مقدمة

In the commercial printing industry, the method of image transfer defines the cost structure, turnaround time, and quality of the final product. For procurement managers and packaging engineers, distinguishing between pressure printing (contact) و non-pressure printing (non-contact) is critical for optimizing supply chains.

While traditional pressure-based methods rely on physical plates and mechanical force to transfer ink, modern non-pressure technologies utilize digital signals to deposit color without direct contact. Understanding the technical nuances of الطباعة بالضغط والطباعة بدون ضغط. helps businesses decide whether to invest in the high-setup, low-unit-cost model of traditional printing or the agile, low-setup model of digital printing.

1. What is Pressure Printing (Contact Imprint)?

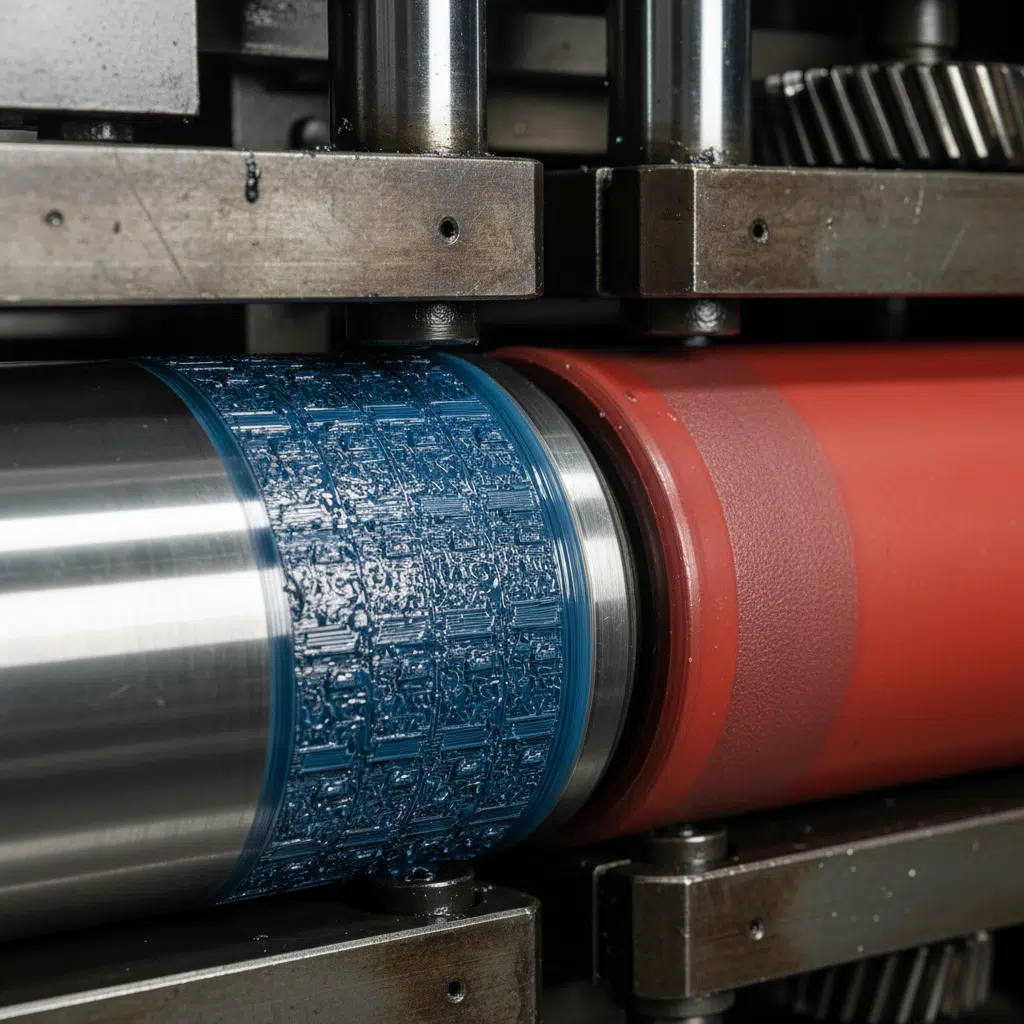

Pressure printing, historically known as contact imprint printing, is the foundation of industrial manufacturing. It operates on a mechanical principle: a physical carrier (the printing plate) transfers graphic information to a substrate (paper, plastic, metal) using direct physical pressure.

This process generally involves five core elements:

- The Substrate: The material being printed on.

- The Plate: The physical relief or chemical surface holding the image.

- The Ink: Viscous or liquid colorants.

- The Machinery: Presses that apply tons of force to ensure transfer.

- Accessories: Blankets, rollers, and dampening systems.

Key Types of Pressure Printing

Based on the structure of the printing plate, contact printing is categorized into four main industrial classes:

- Letterpress (Relief): The image area is raised. Ink is applied to the raised surface and pressed directly onto the paper. While less common for mass commercial work today, it remains popular for luxury stationery and labels due to the tactile indentation it creates.

- Intaglio (Gravure): The image area is etched في the plate (recessed). Ink fills the cells, excess is wiped off, and high pressure pulls the ink out onto the substrate. This is standard for high-volume packaging and currency.

- Lithography (Planographic): The image and non-image areas are on the same flat plane, separated by chemical properties (oil vs. water). Offset lithography is the dominant method for publishing and packaging, using a rubber blanket to transfer the image from plate to paper.

- Stencil (Screen Printing): Ink is forced through a mesh screen. While often manual, industrial rotary screen printing uses pressure to push ink through the stencil onto the substrate.

2. What is Non-Pressure Printing (Non-Contact)?

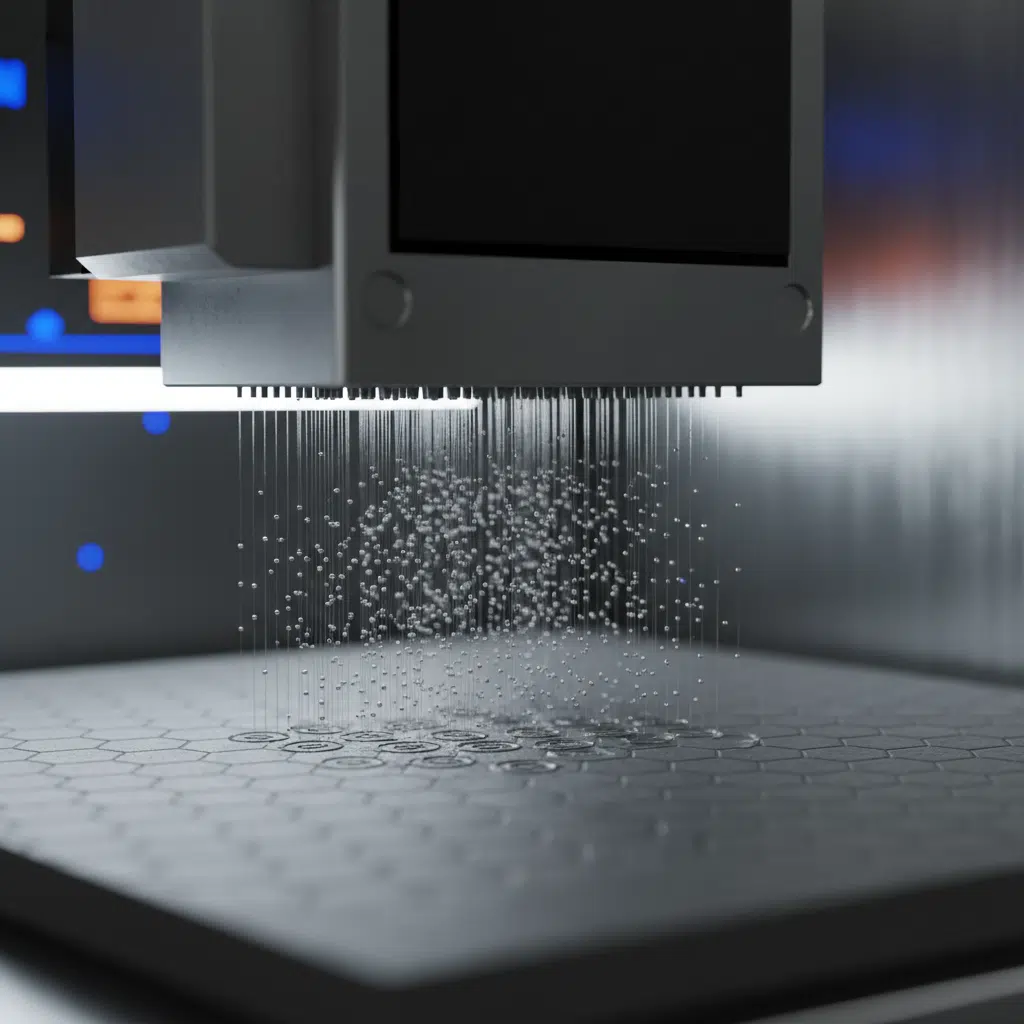

Non-pressure printing, commonly referred to as digital or non-contact printing, eliminates the physical printing plate. Instead of mechanical pressure transferring a static image, this method uses computer-controlled systems to deposit toner or ink droplets directly onto the substrate.

This technology is driven by electronic data, allowing for Variable Data Printing (VDP), where every impression can be different without stopping the press. It is ideal for office environments, short-run packaging, and rapid prototyping.

Key Types of Non-Pressure Printing

- Inkjet Printing: Micro-nozzles spray tiny droplets of ink onto the material. Industrial inkjet heads can print on corrugated board, plastics, and ceramics without touching the surface, preserving the integrity of fragile materials.

- Laser (Electrostatic) Printing: A laser beam creates a static charge on a drum, attracting toner particles which are then fused to the paper using heat. This is the standard for document printing and short-run brochures.

- Thermal Printing: Heat is used to transfer color from a ribbon (thermal transfer) or to activate a heat-sensitive coating on the paper (direct thermal). This is widely used in logistics for barcode labels.

3. Comparative Analysis: Choosing the Right Method

When selecting a vendor or process, buyers must weigh the trade-offs between setup costs and running costs.

| الميزة | Pressure Printing (Contact) | Non-Pressure Printing (Non-Contact) |

|---|---|---|

| تكلفة الإعداد | High (Plates, Make-ready) | Low to None (File-to-print) |

| تكلفة الوحدة | Decreases significantly with volume | Remains relatively flat |

| Speed | Slower setup, extremely fast output | Instant setup, moderate output speed |

| Quality | Superior color accuracy (Pantone) | High quality, but Pantone simulation varies |

| التخصيص | Static images (Same every print) | Variable data (Unique every print) |

| Substrate Variety | Extremely high (Paper, Metal, Foil) | Growing, but limitations exist on textures |

When to Choose Pressure Printing

Pressure printing (specifically Offset or Flexo) is the correct choice when:

- Volume is High: If you are printing 5,000+ copies of a book or 50,000 packaging boxes, the unit cost of pressure printing is a fraction of digital.

- Specific PMS Colors are Required: Brand consistency often requires pre-mixed Pantone inks, which are best applied via offset or flexo stations.

- Special Finishes are Needed: Heavy embossing or metallic foiling often requires the mechanical pressure inherent in these legacy processes.

When to Choose Non-Pressure Printing

Non-contact methods are superior when:

- Speed is Priority: If you need 500 flyers within 24 hours, non-pressure printing bypasses the plate-making process entirely.

- Personalization is Key: Direct mail campaigns requiring unique names or addresses on each piece must be done digitally.

- Substrate is Delicate: Printing on 3D objects or uneven surfaces (like bottles or electronics) is often easier with inkjet heads that do not physically touch the part.

4. Manufacturing and Quality Considerations

For industrial buyers, understanding the quality control (QC) parameters of these methods is essential for drafting specifications.

Registration and Tolerances

In pressure printing, mechanical registration is critical. The substrate must be gripped and moved through multiple color stations (CMYK). Modern presses hold tight tolerances, but slight shifts can occur. In non-pressure printing, registration is digital and often more precise on a single pass, though banding (lines in solid colors) can be a defect in inkjet systems.

Drying and Curing

Pressure printing often uses oxidative drying inks or UV-cured inks. This requires time or high-energy UV lamps. Non-pressure systems, particularly laser, fuse toner instantly with heat, allowing for immediate finishing (cutting/folding). However, toner can sometimes crack on fold lines if not properly scored.

5. Buying Guide: Lead Times and MOQs

الحد الأدنى لكميات الطلبات (MOQ):

- Pressure: Expect MOQs ranging from 1,000 to 5,000 units depending on the complexity. The cost of making plates makes small runs economically unviable.

- Non-Pressure: MOQs can be as low as 1 unit. This allows for “Just-in-Time” (JIT) manufacturing strategies, reducing inventory warehousing costs.

Artwork Preparation:

- For pressure printing, files must be separated into color plates (CMYK + Spots) with bleed and trap settings carefully managed.

- For non-pressure, standard high-resolution PDFs are usually sufficient, as the RIP (Raster Image Processor) handles color management.

الأسئلة المتداولة

Is non-pressure printing cheaper than pressure printing?

It depends on volume. For short runs (e.g., under 1,000 units), non-pressure is cheaper because there are no plate costs. For long runs, pressure printing is significantly cheaper per unit.

Can I use Pantone colors in non-contact printing?

Most non-contact digital presses simulate Pantone colors using CMYK (or extended gamuts like CMYKOV). While close, they are not 100% accurate matches compared to the pre-mixed inks used in pressure printing.

Which method is better for eco-friendly packaging?

Both have merits. Non-pressure printing reduces waste by eliminating plates and chemicals associated with make-ready. However, pressure printing uses vegetable-based inks and is more efficient for mass production, reducing the carbon footprint per unit.

Does non-contact printing last as long as contact printing?

Generally, yes. Modern UV-cured inkjet and fused toner are highly durable. However, for outdoor applications exposed to direct sunlight, specific UV-resistant inks (often used in screen pressure printing) may still offer superior longevity.

الخاتمة

The distinction between pressure and non-pressure printing lies in the mechanics of transfer: physical force versus digital deposition. For large-scale industrial runs, packaging, and publishing, the economies of scale provided by contact methods like offset and flexography remain unbeatable. Conversely, for rapid turnaround, variable data, and short runs, non-contact digital solutions offer unmatched flexibility.

Selecting the right method requires analyzing your project’s volume, substrate, and timeline.

Need help determining the best printing method for your next project? طلب عرض أسعار or contact our technical team today to discuss your specifications.