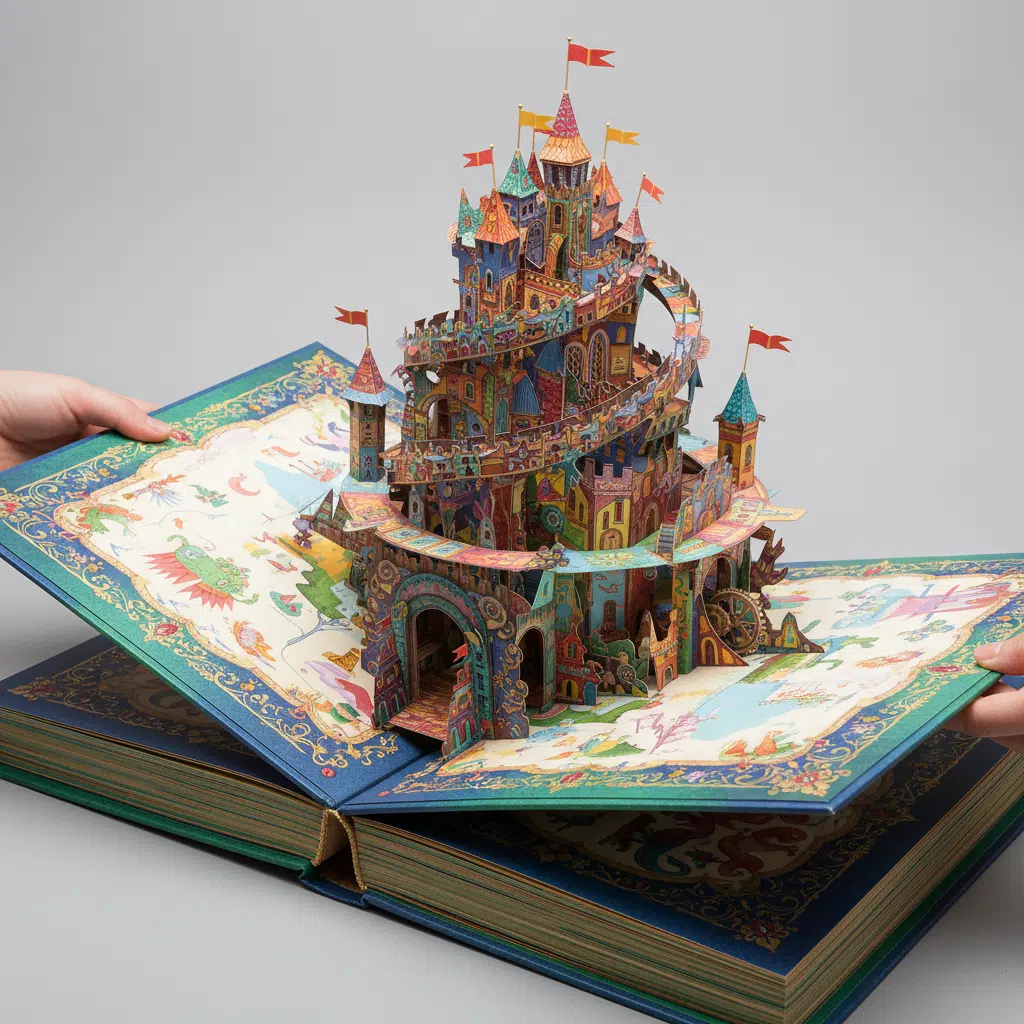

Pop-up books are among the most complex and engaging print products on the market. Unlike standard flat books, they require a unique blend of creative artistry, structural engineering, and precise manufacturing. For publishers and independent authors, bringing a pop-up book to life is not just about printing ink on paper; it is a three-dimensional construction project that demands rigorous planning and skilled labor.

Choosing the right manufacturing partner is critical. The difference between a functional, durable pop-up book and one that tears upon the first opening often lies in the quality of the cardstock, the precision of the die-cutting, and the expertise of the hand assembly team. This guide explores the end-to-end process of custom pop-up book printing, from the initial paper engineering to final quality assurance.

The Role of Paper Engineering

Before a single sheet is printed, the mechanics of the book must be perfected. This phase is known as paper engineering. While the illustrator provides the visual art, the paper engineer designs the folding mechanisms (V-folds, parallelograms, pull-tabs, and wheels) that make the illustrations move.

From Concept to White Dummy

The standard industry practice begins with a “white dummy.” This is a full-scale, unprinted prototype constructed from the actual cardstock intended for production. It serves several purposes:

- Feasibility Check: It ensures that the pop-ups fold flat when the book is closed without bulging or tearing.

- Nesting Layout: It helps the factory determine how to arrange the different parts on a press sheet to minimize paper waste.

- Cost Estimation: The complexity of the assembly directly impacts labor costs. A white dummy allows the manufacturer to calculate exactly how many manual gluing points and assembly steps are required.

Publishers should approve the white dummy before finalizing any artwork files to ensure the die-lines match the physical mechanics perfectly.

Material Selection for Durability

Interactive children’s books face rigorous handling. Standard text paper is insufficient for the structural elements of a pop-up. The choice of material dictates the book’s longevity and the “snap” of the pop-up action.

Recommended Paper Stocks

- C1S Art Board (250gsm – 350gsm): Coated on one side, this is the standard for pop-up elements. It offers stiffness for structural integrity while allowing glue to adhere effectively to the uncoated side.

- Solid Bleached Sulfate (SBS): A premium grade board that provides excellent elasticity, ensuring pop-ups spring back into shape repeatedly without cracking at the fold lines.

It is also crucial to select the right adhesives. Industrial-grade, non-toxic glues are required to ensure parts stay attached even after hundreds of openings, while complying with international safety standards for children’s products.

The Manufacturing Process: Precision and Labor

Manufacturing a pop-up book is vastly different from producing a standard hardcover. It involves three distinct stages: printing, die-cutting, and assembly.

1. High-Fidelity Offset Printing

Because pop-up books are visual-heavy, color consistency is paramount. Offset printing is the preferred method, offering sharp resolution and vibrant colors. Sheets are often printed with a protective coating (lamination or aqueous varnish) to prevent cracking when the paper is folded.

2. Precision Die-Cutting

This is where accuracy is non-negotiable. Every individual piece of the pop-up—whether it’s a character, a tree, or a pull-tab—must be cut out of the press sheet using a custom-made steel die. Even a millimeter of deviation can cause a mechanism to jam. The die-cutting machine punches out the shapes and scores the fold lines simultaneously.

3. Hand Assembly (The Critical Differentiator)

Unlike standard binding, which is automated, pop-up books are largely assembled by hand. Skilled workers sit at assembly lines, folding, gluing, and inserting tabs into slots. Complex books may require dozens of assembly steps per page.

This labor-intensive process is why lead times for pop-up books are longer than standard books. A factory with experienced assembly teams is essential to maintain consistency across thousands of units.

Quality Control and Safety Testing

For B2B buyers and publishers, quality assurance (QA) is the final hurdle. Defective pop-ups can lead to high return rates and brand damage.

Standard QA checks include:

- Functionality Testing: Opening and closing the book repeatedly to ensure mechanisms do not catch or tear.

- Tension Checks: Ensuring pull-tabs move smoothly but have enough friction to stay in place.

- Safety Compliance: Verifying that small parts are securely attached (choke hazard prevention) and that inks/glues meet safety standards like EN71 or ASTM.

Buying Guide: Key Considerations for Publishers

When requesting a quote for custom pop-up book printing, providing detailed specifications is essential for an accurate price.

| العامل | التوصية |

|---|---|

| موك (الحد الأدنى لكمية الطلب) | Due to complex setup and hand assembly, MOQs are typically higher (often 1,000+ units) to make the unit cost viable. |

| المهلة الزمنية | Allow 4–8 weeks for production after the white dummy is approved, depending on complexity. |

| إعداد الملفات | Separate layers for print design and die-lines (cut lines vs. fold lines). |

الأسئلة الشائعة (FAQs)

Can you help design the pop-up mechanisms?

Most printing manufacturers focus on production. While some may offer structural advice, publishers typically need to hire a specialized paper engineer to create the initial mechanics. The factory then adapts these designs for mass production.

Why is the white dummy stage mandatory?

The white dummy confirms that the 2D design works in 3D reality. It allows the factory to identify potential failures and accurately price the manual assembly labor required.

What affects the cost of a pop-up book most?

The number of “points of assembly” (gluing spots) is the biggest cost driver. A book with 5 complex pop-ups per page will cost significantly more to assemble than one with 1 simple pop-up per page, regardless of the page count.

How do I ensure the books are safe for children?

Work with a manufacturer experienced in children’s book exports. Specify that materials must pass safety standards (like CPSIA or EN71) and request compliance testing if necessary.

Ready to Print Your Interactive Book?

Producing a custom pop-up book requires a partnership with a manufacturer who understands the intricacies of paper engineering and manual assembly. At YBJ Printing, we combine advanced offset capabilities with skilled hand-craftsmanship to deliver durable, high-quality movable books.

Contact us today to discuss your project or request a sample of our previous work.