Enhancing Value Through Functional Customization

In the competitive stationery market, the difference between a generic notebook and a premium product often lies in the finishing details. For procurement officers and brand managers, understanding the manufacturing nuances of custom notebook accessories is essential. Accessories like elastic closures, ribbon markers, and expandable pockets are not merely decorative; they determine the functionality, durability, and perceived value of the final product.

This guide addresses the technical specifications, material options, and quality considerations for the most requested add-ons in custom planner printing. Whether you are sourcing for a retail stationery brand or a large-scale corporate gifting project, selecting the right accessories ensures your product meets international standards for quality and usability.

1. Elastic Band Closures: Materials and Attachment

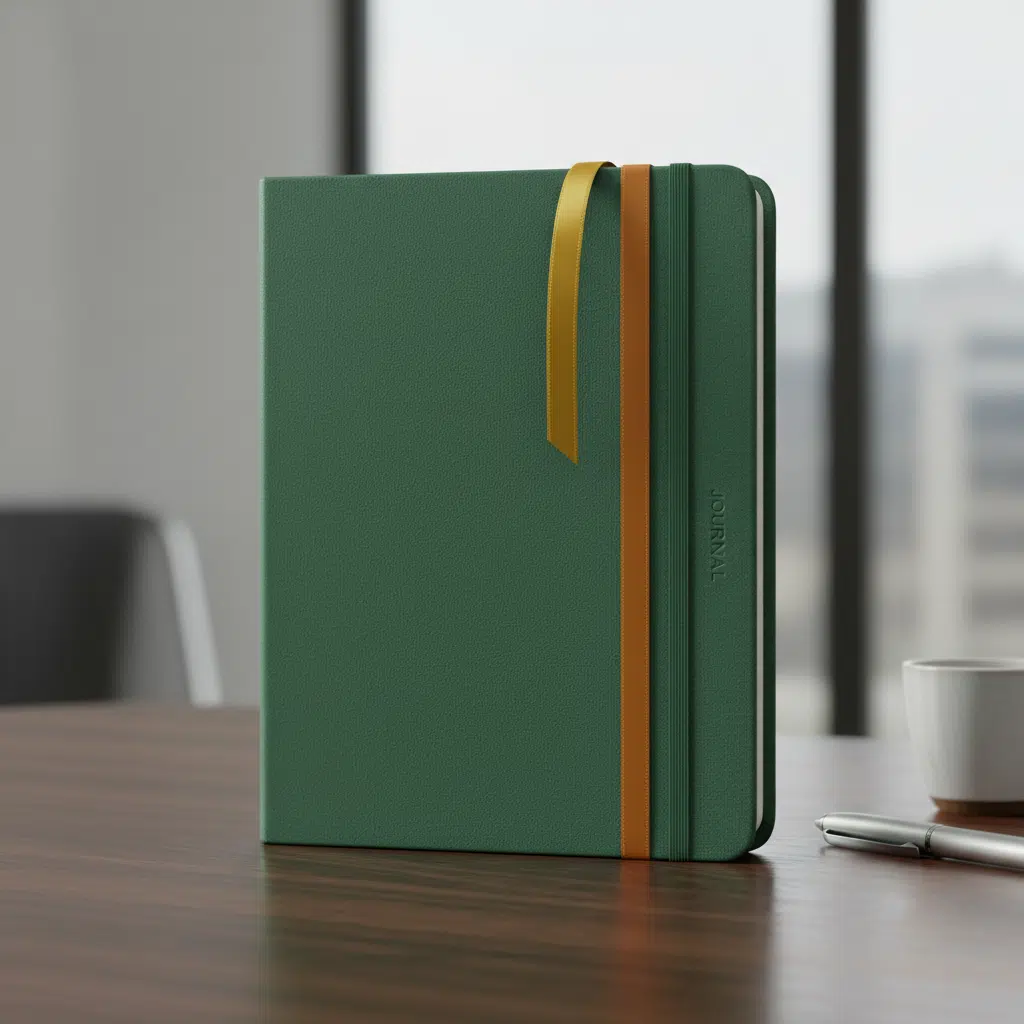

The elastic band closure is a standard feature for hardcover journals, serving to keep the book closed and protect the pages. However, the quality of elastic varies significantly between manufacturers.

Material Composition

Most industrial elastic bands used in journal printing in China are composed of polyester or nylon fibers woven over rubber cores.

- Polyester: Cost-effective and durable. It holds color well but has a slightly coarser texture.

- Nylon: Offers a smoother, shinier finish and higher elasticity retention over time. It is often preferred for luxury segments.

Mounting Styles

Back Cover Mounting: The standard method involves threading the elastic through two punched holes in the back cover board before the endpaper is glued down. This hides the attachment points, providing a clean look.

Spine Mounting: Less common for hardcovers but seen in some softcover designs, where the band wraps vertically.

Technical Considerations

- Width: Standard widths are 7mm, 10mm, and 15mm. Heavier books (e.g., A4 daily planners) require 10mm or wider bands to maintain tension without rolling.

- Tension: The band must be cut to a precise length relative to the book thickness. If too tight, it warps the cover; if too loose, it slides off.

- Color Matching: Bands can be dyed to specific Pantone (PMS) codes. Note that custom dyeing usually requires higher Minimum Order Quantities (MOQ) compared to stock colors (black, white, navy, red).

2. Ribbon Markers (Bookmarks)

Ribbon markers add immediate utility to planners and diaries. While they seem simple, fraying ends and poor attachment are common failure points in low-quality manufacturing.

Ribbon Types

The two primary weaves used in professional bookbinding are:

- Satin Ribbon: Smooth, glossy surface. Available in single-face (glossy on one side) or double-face (glossy on both). Double-face satin is the industry standard for premium journals.

- Grosgrain Ribbon: Ribbed texture, matte finish. Highly durable and offers a distinct tactile feel, often used for tactical or rugged-style notebooks.

Manufacturing Specs

- Attachment: Ribbons are glued to the head of the book block (the spine edge) before the cover is cased in. High-quality adhesive must be used to prevent the ribbon from pulling out under tension.

- Heat Sealing: To prevent fraying, the exposed end of the ribbon must be heat-cut or heat-sealed. Diagonal cuts are standard, but V-cuts are also an option.

- Quantity: Multi-ribbon markers (2 or 3 per book) are trending for complex planners, allowing users to mark monthly, weekly, and daily sections simultaneously.

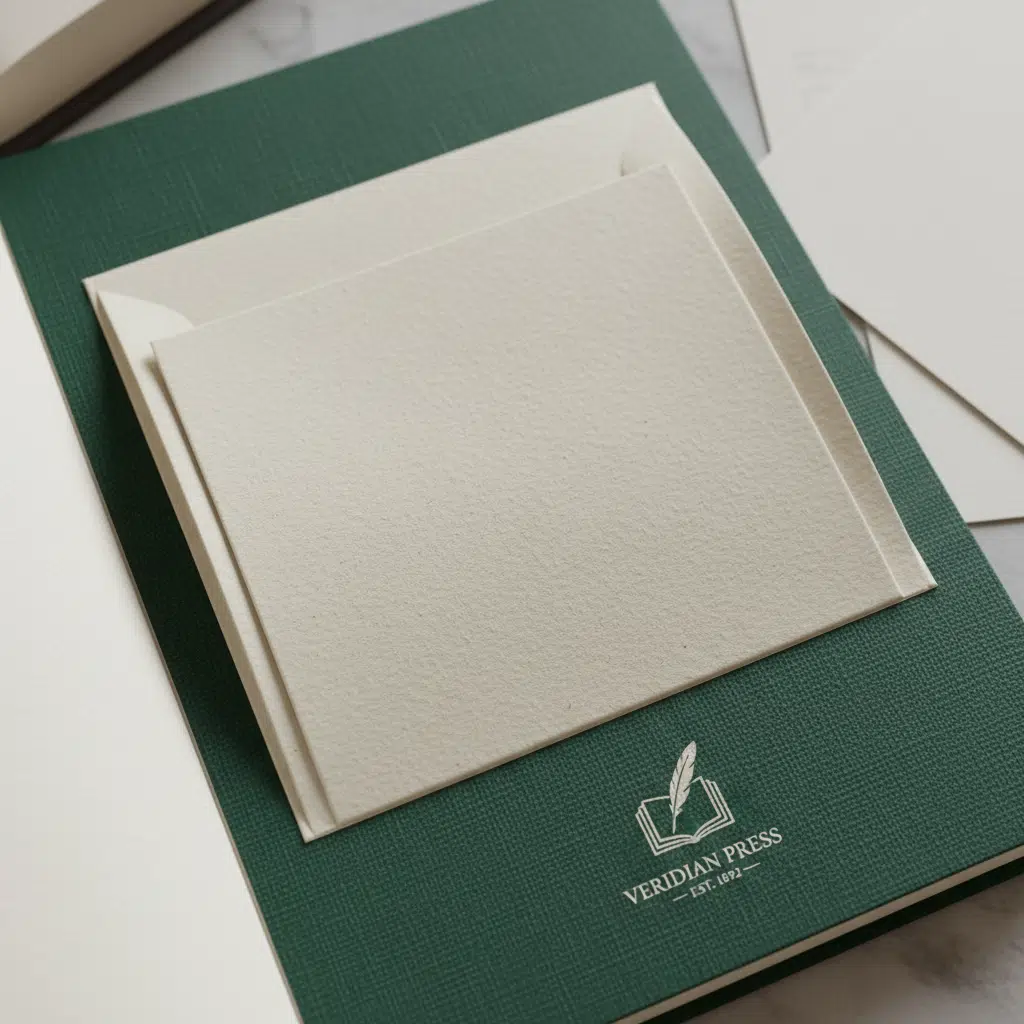

3. Expandable Inner Pockets

Located on the inside back cover, expandable pockets are complex components requiring precise die-cutting and assembly. They are typically used to store loose notes, receipts, or business cards.

Construction

The pocket is usually made from the same cardstock as the endpapers, or a slightly heavier weight (e.g., 180gsm to 250gsm) to ensure structural integrity. The “gussets” (the folding sides) are often reinforced with a durable fabric strip or tear-resistant paper to withstand repeated opening and closing.

Quality Checkpoints

- Adhesion: The pocket must be securely glued to the back endpaper. Insufficient glue leads to separation when the pocket is stuffed.

- Clearance: The pocket must be sized correctly so it does not interfere with the book closing or protrude beyond the cover edge.

4. Additional Functional Add-ons

Pen Loops

Pen loops solve the perennial problem of lost writing instruments.

- Elastic Loops: A loop of elastic sewn into a tag and glued between the endpaper and cover board.

- Adhesive Loops: Sold separately or attached during packing.

- Integration: Ensure the loop size (diameter) matches the target pen type. A standard 15mm flat elastic loop fits most ballpoints, but may be tight for fountain pens.

Die-Cut Tabs and Indexing

For dated planners, die-cut thumb indices allow quick navigation to specific months. This requires specialized cutting dies and precise registration during the printing process to ensure the text aligns with the cut.

Comparison: Standard vs. Custom Accessories

| الميزة | Stock Options | Fully Custom Options |

|---|---|---|

| Color | Limited range (Black, White, Grey, Navy, Red) | Exact Pantone (PMS) Match |

| موك | Lower (often 500-1,000 units) | Higher (often 3,000+ units depending on material) |

| المهلة الزمنية | Standard production timeline | Adds 7-10 days for dyeing/sourcing |

| Branding | None | Printed logos on ribbons; woven logos on elastic |

Manufacturing and Quality Assurance

When outsourcing custom planner printing, it is crucial to define quality standards in your purchase order. A professional manufacturer should perform the following checks:

- Pull Testing: Elastic bands and ribbons are subjected to tension tests to ensure they do not detach from the binding.

- Fray Testing: Ribbons are inspected for proper heat sealing.

- Functionality Check: Random samples are checked to ensure pockets open fully without tearing and elastic bands provide the correct tension (neither warping the cover nor hanging loose).

Buying Guide for Custom Notebooks

الحد الأدنى لكميات الطلب (موك)

While basic notebooks can be produced in smaller batches, highly customized accessories often drive up the MOQ. For example, custom-dying elastic to a specific brand color usually requires a minimum procurement of material that translates to 1,000 to 3,000 books. If your volume is lower, consider choosing a complementary stock color instead of a direct match.

Artwork and Specifications

When submitting your design files:

- Specify the Pantone code for all non-paper elements (elastics, ribbons).

- Indicate the positioning of the elastic (distance from the edge).

- For printed ribbons, provide vector artwork (AI or PDF) of the logo to be repeated.

الأسئلة المتداولة

Can I print my logo on the elastic band?

Yes. Logos can be screen printed (silicone print) onto the elastic, or woven directly into the fabric (jacquard weave). Woven options are more durable but require higher MOQs.

Are expandable pockets standard in all journals?

No, they are an add-on. You must request them specifically. They add slightly to the unit cost and the thickness of the book block.

What is the best ribbon width for an A5 notebook?

The standard is 7mm or 8mm. For a bolder look, 10mm ribbons are used. Oversized A4 planners may use 15mm ribbons.

Can I mix and match accessory colors?

Absolutely. A popular design trend is to have the elastic band color contrast with the cover color, or to have two ribbon markers in different shades.

How do I ensure the elastic doesn’t lose its stretch?

Specify “high-density nylon elastic” in your tech pack. This material retains elasticity significantly longer than standard polyester options.

Ready to produce premium custom planners?

Selecting the right accessories is key to creating a product that stands out in the market. At YBJ Printing, we specialize in high-specification journal printing in China, offering a wide range of custom materials and finishes.

طلب عرض أسعار today or ask for a sample kit to see our accessory quality firsthand.