From Digital Design to Physical Ink: Why Pre-Press Matters

In the world of professional offset printing, the transition from a digital file on a screen to a physical book, box, or deck of cards is a critical phase. Unlike digital printing, which allows for quick, low-cost adjustments, offset printing involves the creation of physical plates and significant setup time. An error in the manuscript file—such as incorrect color modes or missing bleeds—can result in production delays or costly reprints.

For self-publishers, brand owners, and procurement managers, understanding the technical requirements of industrial printing is essential. A well-prepared "print-ready" file ensures that the final product matches the designer’s vision and flows smoothly through the manufacturing process without interruption.

1. Color Mode: Converting RGB to CMYK

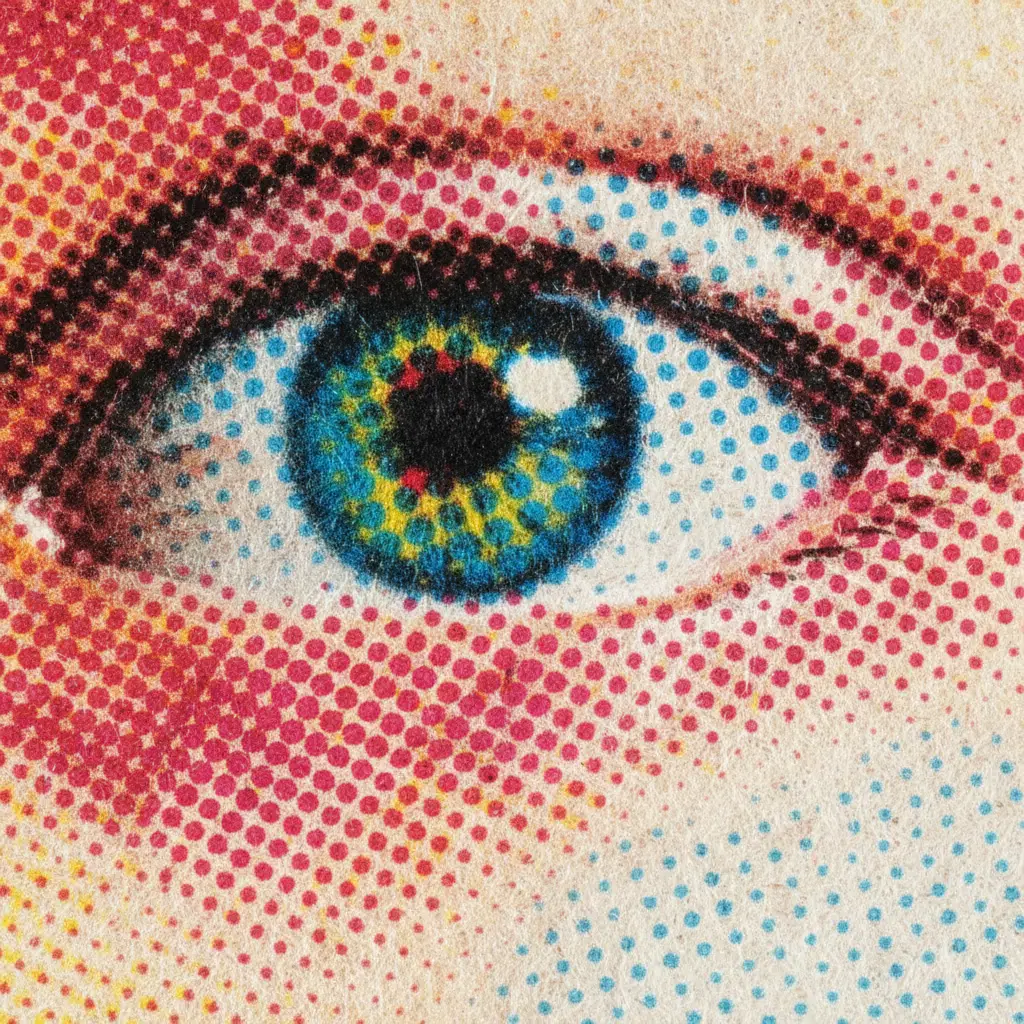

The most common error in file preparation is submitting artwork in RGB (Red, Green, Blue). RGB is an additive color model used for screens, where light is projected to create color. Offset printing, however, is a subtractive process using physical ink on paper, specifically the four-color process: Cyan, Magenta, Yellow, and Key (Black), known as CMYK.

The Color Gamut Shift

Many bright, neon-like colors visible on a computer monitor fall outside the printable CMYK gamut. If you submit an RGB file, the ripping software (RIP) at the print factory will automatically convert it to CMYK. This automated conversion often results in duller, muddy colors that do not match your expectations.

Action Step: Convert all images and document color modes to CMYK before finalizing your layout. If you require a specific brand color that cannot be achieved via CMYK (such as a fluorescent or metallic hue), you must specify a Pantone (PMS) spot color.

2. Resolution: The 300 DPI Standard

Screen resolution is typically 72 DPI (dots per inch), which looks crisp on a monitor but pixelated and blurry when printed on an offset press. For professional high-quality printing, all raster images (photos, textures) must be at least 300 DPI at their actual print size.

- Vector Graphics: Logos and text should ideally be vector-based (AI, EPS, or PDF). Vectors are resolution-independent and will remain sharp at any size.

- Upscaling Warning: Do not simply change the resolution setting of a low-quality image in Photoshop. This does not add detail; it merely adds blur. You must source high-resolution assets from the start.

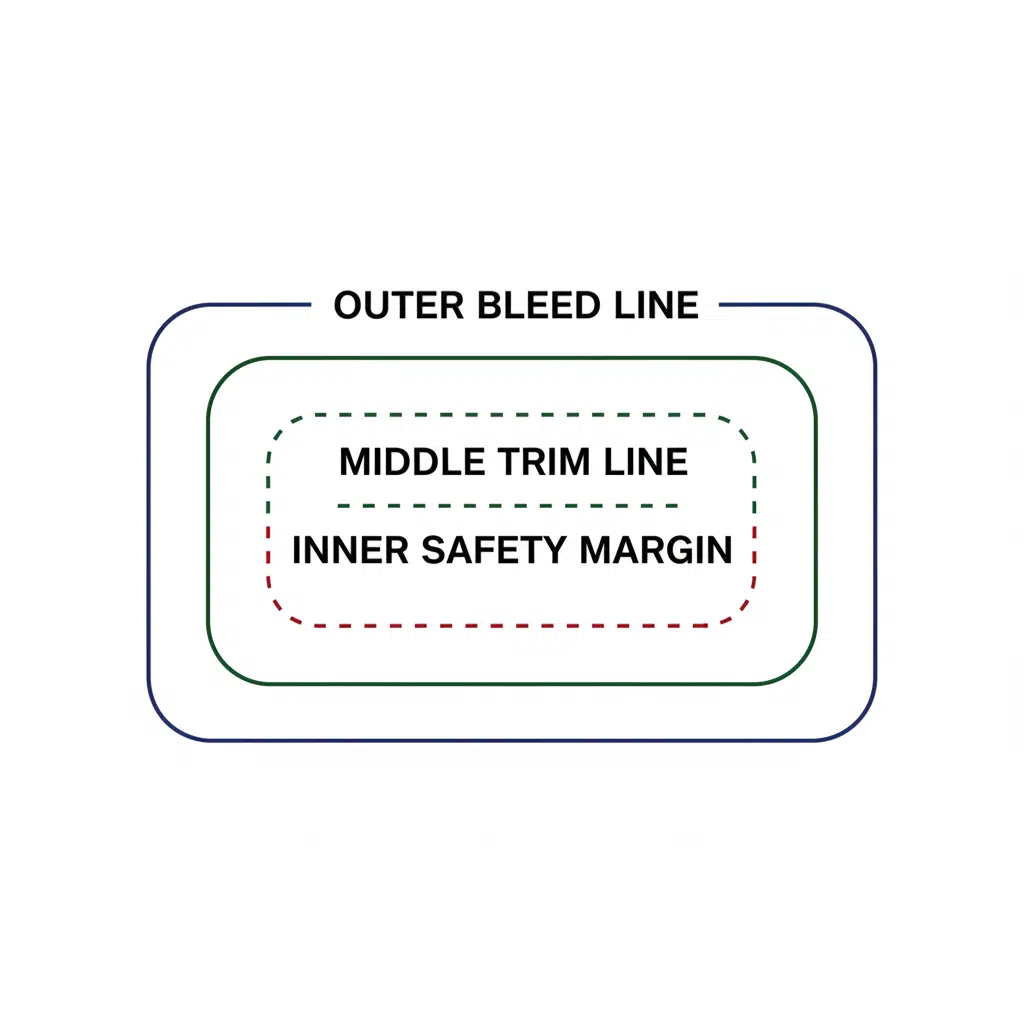

3. Bleed, Trim, and Safety Margins

Industrial cutting machines handle thousands of sheets at once. While modern guillotines are precise, there is always a mechanical tolerance (often ±1mm). To account for this, your file must include specific structural elements.

Understanding the Terminology

- Trim Line: The final size of the product after cutting.

- Bleed Area: Artwork that extends beyond the trim line. Standard bleed is usually 3mm (0.125 inches) on all sides. If your design has a background color or image that goes to the edge of the page, it must extend into the bleed area to prevent thin white strips from appearing if the cut shifts slightly.

- Safety Margin (Safe Zone): A buffer zone inside the trim line, typically 3mm to 5mm. Critical elements like page numbers, text, and logos must be kept within this zone to ensure they are not cut off.

4. Managing Black Values: Rich Black vs. Standard Black

In offset printing, not all blacks are created equal. Using the wrong type of black can affect readability and drying times.

Standard Black (100% K)

Use this for body text, barcodes, and thin lines. It uses only black ink, ensuring crisp edges. If you use a composite black for small text, slight misregistration between the four plates can cause the text to look blurry or have colored halos.

Rich Black (e.g., C:60 M:40 Y:40 K:100)

Use this for large backgrounds or solid blocks of black. Standard black can look dark gray or washed out when covering large areas. Adding percentages of Cyan, Magenta, and Yellow creates a deeper, darker "Rich Black." However, avoid exceeding a Total Ink Limit (TIL) of 300%, as this can cause ink smearing and drying issues.

5. PDF Export Settings for Manufacturing

When your layout is complete, the final step is exporting the file. We recommend adhering to the PDF/X-1a:2001 standard, which is widely accepted in the industry. This standard flattens transparency and embeds fonts, reducing the risk of errors.

Checklist for Export:

- تضمين جميع الخطوط: Ensure all typefaces are embedded so they render correctly on the factory’s system.

- Flatten Layers: Complex transparencies should be flattened to prevent rendering glitches.

- Single Pages vs. Spreads: Generally, printers require files as single pages in consecutive order, not reader spreads (e.g., page 2 and 3 side-by-side). The imposition software at the factory will arrange the pages for the printing plates.

6. The Proofing Process

Once you submit your files, the pre-press department will typically provide a proof. Understanding the type of proof is vital for quality assurance.

- Soft Proof (Digital Proof): A PDF sent via email to check content, text accuracy, and pagination. It is not accurate for color matching due to screen calibration differences.

- Hard Proof (Wet Proof or Digital Print): A physical sample. A "wet proof" is printed on the actual offset press (expensive), while a high-quality digital print (Epson proof) is common for checking color approximate to the final output.

Summary: Your Pre-Press Checklist

| Element | Requirement |

|---|---|

| Color Mode | CMYK (No RGB or Spot colors unless intended) |

| Resolution | Minimum 300 DPI for images |

| Bleed | 3mm (0.125″) on all sides |

| Text Black | 100% K (C0 M0 Y0 K100) |

| File Format | PDF (Single pages, fonts embedded) |

الأسئلة الشائعة (FAQs)

Can I use Canva for offset printing files?

While Canva is great for digital assets, it often defaults to RGB and lacks advanced control over bleed and color separation. If you must use it, ensure you export with "PDF Print" settings and select "Crop marks and bleed," but professional software like Adobe InDesign is preferred for bulk manufacturing.

What is the difference between coating and lamination in file setup?

Usually, these finishes do not require changes to the artwork layer itself, but if you are using Spot UV or Foil Stamping, you must provide a separate layer or file in 100% K (black) indicating exactly where the finish should be applied.

Why do colors look different on paper than on my screen?

Screens emit light (RGB), while paper reflects light (CMYK). Additionally, the paper stock (coated vs. uncoated) affects ink absorption. Uncoated paper absorbs more ink, causing colors to appear slightly darker and less vibrant than on coated glossy paper.

Do I need to include crop marks?

Most professional printers prefer files without crop marks, provided the document page size includes the bleed. However, always confirm this with your account manager before exporting.

Preparing a manuscript for offset printing requires attention to detail, but it guarantees a professional, durable result that stands out in the market. If you are ready to move from design to production, our team is here to guide you through the technical specifications.