In an era dominated by digital media and mass-market paperbacks, the tactile experience of a physical book has become a primary differentiator for luxury publishers. Cloth bound books—specifically those utilizing linen, silk, or high-end rayon blends—signal permanent value and archival quality. For art book creators, corporate archivists, and limited-edition publishers, the choice of cover material is not merely aesthetic; it is a structural decision that impacts the binding process, decoration options, and longevity of the final product.

This guide explores the technical and aesthetic considerations of manufacturing cloth bound books, focusing on material properties, foil stamping compatibility, and production requirements for high-quality B2B printing projects.

Why Choose Fabric for Hardcover Binding?

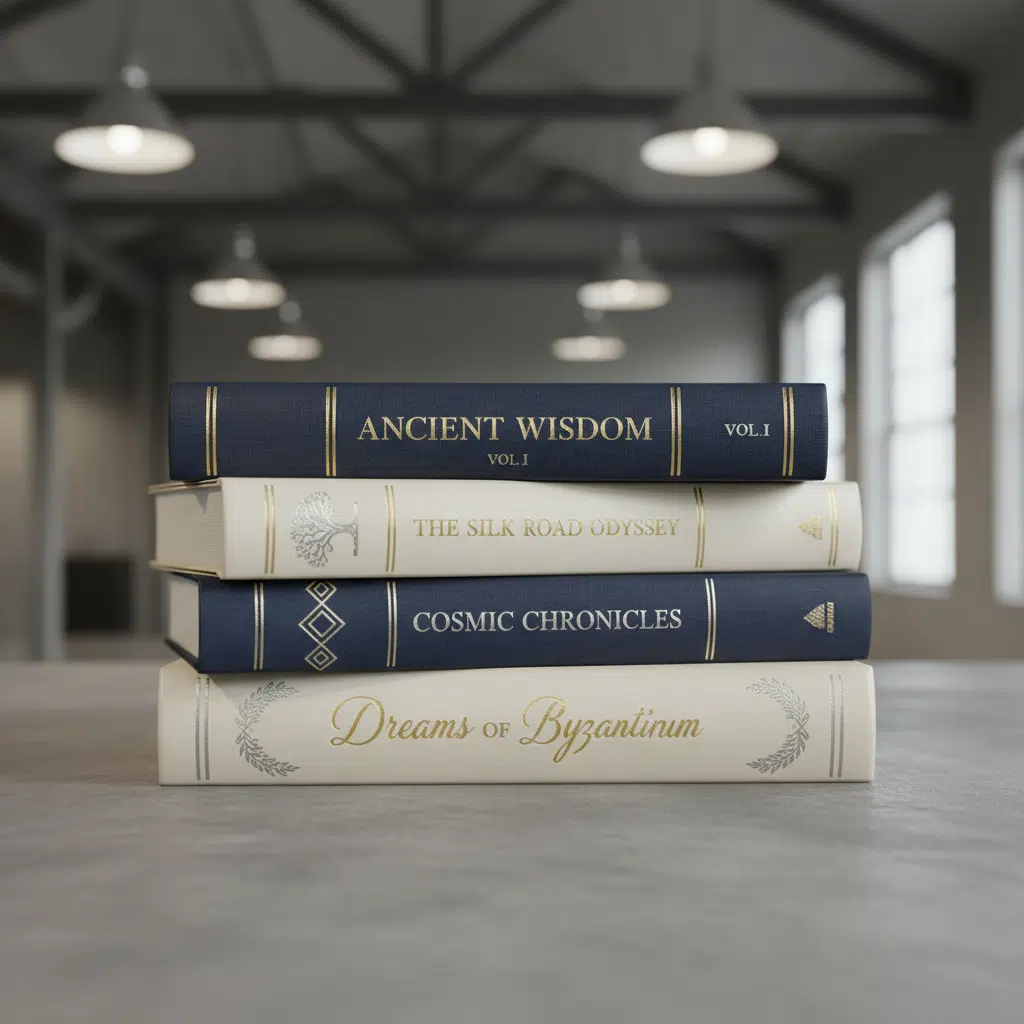

Fabric binding, historically known as "quarter binding" or "full cloth binding," elevates a publication beyond the standard printed paper case (PPC). While a printed cover allows for full-color photography, cloth offers texture, durability, and a classic sensory appeal that printed lamination cannot replicate.

From a manufacturing perspective, premium book cloth is engineered specifically for the casing-in process. Unlike raw fabric purchased from a textile shop, bookbinding cloth comes backed with paper (paper-backed). This backing is critical for two reasons:

- Glue Barrier: It prevents adhesives from seeping through the weave and staining the fabric surface.

- Dimensional Stability: It reduces stretching and warping during the mechanical casing-in process, ensuring the cover boards remain flat.

Material Comparison: Linen vs. Silk and Fine Fabrics

Selecting the right fabric involves balancing texture, durability, and cost. Here is how the most common options compare in an industrial printing context.

Linen and Cotton Blends

Linen is the most popular choice for premium editions. It is derived from the flax plant (or simulated with high-quality cotton blends) and offers a natural, matte finish.

- Textura: Ranges from "fine weave" (tight, smooth, suitable for detailed stamping) to "coarse" or "canvas" style (rough, highly tactile).

- Durabilidad: Excellent scuff resistance and tensile strength.

- Las mejores aplicaciones: Art monographs, heritage editions, corporate yearbooks, and coffee table books.

- Production Note: Coarse weaves may require deeper foil stamping dies to ensure the foil adheres to the valleys of the fabric texture.

Silk, Rayon, and Satin Finishes

When publishers request "silk," the industry standard is often a high-quality rayon or viscose blend that mimics the luster of silk but offers superior durability and colorfastness. Real silk is fragile and sensitive to light.

- Textura: Smooth, lustrous, and elegant. It reflects light differently than linen.

- Durabilidad: More delicate. These fabrics are prone to water spotting and fraying if not handled correctly during production.

- Las mejores aplicaciones: Luxury fashion lookbooks, jewelry catalogs, and limited-edition poetry collections.

- Production Note: Due to the smooth surface, these materials are excellent for fine-line foil stamping and screen printing but require strict quality control to avoid fingerprints during assembly.

Decoration Techniques for Cloth Covers

Cloth covers cannot be printed on using standard offset lithography. Instead, they require post-press decoration techniques that physically alter the surface or adhere material to it.

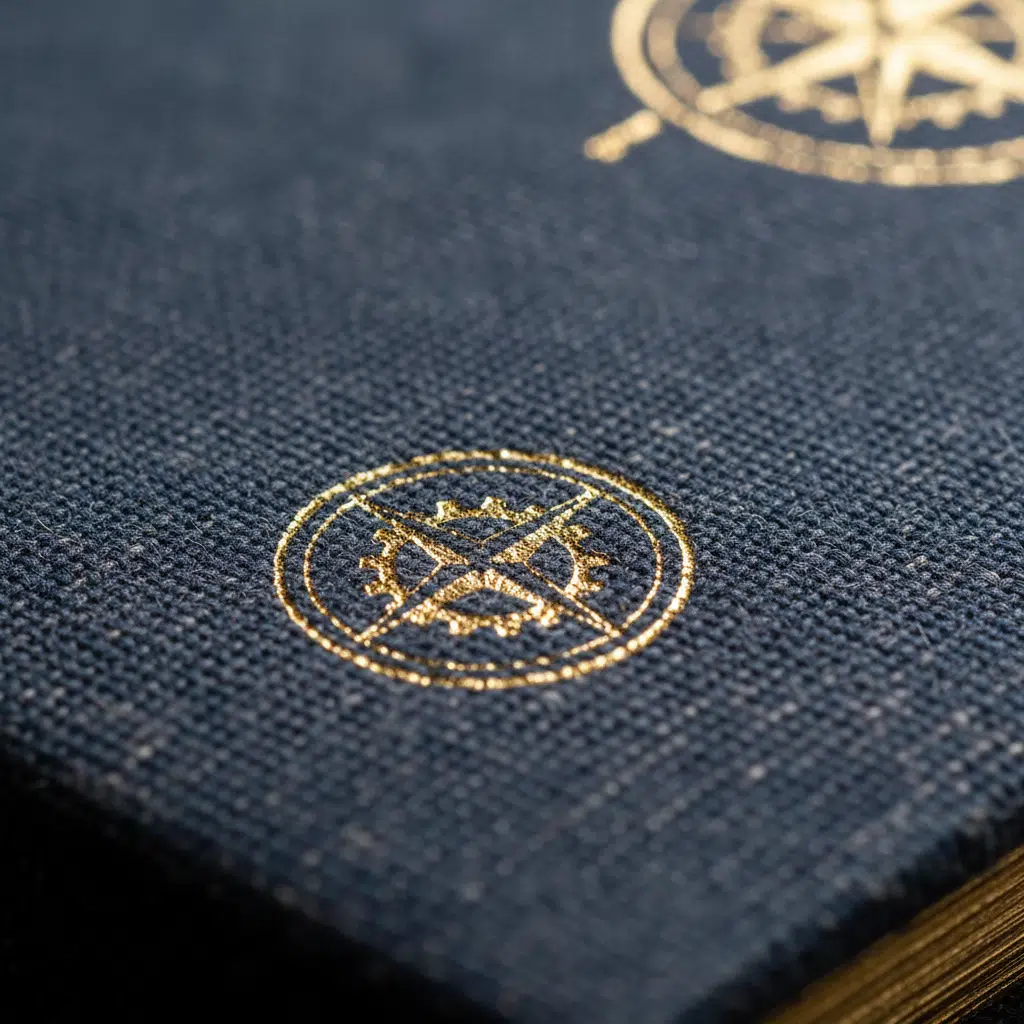

Hot Foil Stamping

Foil stamping is the definitive method for titling cloth books. A heated metal die transfers a thin layer of metallic or pigment foil onto the fabric.

- Metallic Foils: Gold, silver, copper, and rose gold are standard. They provide high contrast against dark linens.

- Pigment Foils: Matte colors (white, black, red) used for a modern, minimalist look.

- Technical Requirement: The "dwell time" and pressure must be calibrated based on the fabric’s weave. A rough linen requires more pressure to break the grain than a smooth silk.

Debossing (Blind Stamping)

Debossing presses a design into the cover board without ink or foil, creating a sunken relief. On cloth, this creates a subtle, tactile effect. It works best on thicker fabrics where the shadow play highlights the texture.

Tipping-In Images

Since photos cannot be printed directly onto dark cloth with high fidelity, a common solution is "tipping in." A printed image (usually on high-quality coated paper) is manually glued into a debossed area (a "well") on the front cover. This combines the tactile luxury of cloth with the visual impact of full-color photography.

Production and Quality Considerations

Manufacturing a cloth bound book involves specific quality control steps to ensure the final product meets premium standards.

Dirección del grano

The grain of the greyboard, the endpapers, and the book cloth must all run parallel to the spine. If the grain directions cross, the cover will warp (curl) when exposed to humidity changes. This is a non-negotiable specification for professional book manufacturing.

Board Thickness

Premium cloth books typically use greyboard ranging from 2.5mm to 3.5mm thick. Thicker boards provide a substantial, heavy feel appropriate for the cost of the materials.

Rub Testing

Before mass production, we recommend performing rub tests on the foil stamping. Cloth surfaces can be abrasive; the foil must adhere strongly enough that it does not flake off when the book is slid in and out of a shelf or slipcase.

Buying Guide for Publishers

When requesting a quote for cloth bound projects, consider the following parameters to ensure accurate pricing and lead times.

- Material Selection: Do you need a standard stock color (lower MOQ, faster lead time) or a custom-dyed fabric (high MOQ, longer lead time)?

- Dust Jackets vs. Slipcases: Cloth books often forgo dust jackets to show off the fabric. However, a slipcase (also cloth-wrapped or printed) offers excellent protection and increases the perceived value.

- Head & Tail Bands: These small fabric strips at the top and bottom of the spine should color-match or contrast intentionally with the cover cloth.

- Preparación del expediente: Artwork for foil stamping must be vector-based (AI or EPS) with no gradients. Lines should typically be at least 0.5pt thick to ensure the die can hold the detail.

FAQ: Cloth Bound Book Manufacturing

Q: What is the Minimum Order Quantity (MOQ) for custom cloth colors?

Typically, custom dyeing requires ordering full rolls of fabric (often 1,000+ meters). However, standard stock colors are available for smaller print runs (e.g., 500–1,000 units).

Q: Can you print full color on cloth?

Direct offset printing is not possible on most book cloths. Screen printing is possible for simple spot colors. For full-color imagery, we recommend tipping-in a photo or using a printed dust jacket.

Q: Is linen more expensive than printed paper cases?

Yes. The material cost is higher, and the assembly process (especially with foil stamping and debossing) is slower and more labor-intensive.

Q: How do I choose the right foil color?

We advise testing. A foil color might look different on a dark blue linen compared to a white silk due to contrast and light reflection. Ask for a swatch test or a wet proof of the cover.

Start Your Premium Edition Project

Cloth bound books remain the gold standard for luxury publishing. Whether you require the rugged authenticity of natural linen or the refined sheen of silk, selecting the right materials and decoration techniques is vital for a successful print run.

Ready to explore material options? Contact us today to request a quote or view our sample books containing a wide range of fabric swatches and foil applications.