When finalizing a print project, particularly for book covers, catalogs, or rigid boxes, the choice of lamination is not merely an aesthetic decision—it is a functional one. The finish you select determines how the product handles wear, how colors appear, and the immediate tactile impression it makes on the end-user.

For procurement managers and publishers, the debate often comes down to two distinct options: the high-shine durability of gloss lamination versus the premium, velvet-like feel of soft touch lamination. Both offer protection against moisture and tearing, but they interact with ink and handling very differently.

This guide compares soft touch and gloss lamination across durability, scuff resistance, and production costs to help you specify the right finish for your next bulk printing order.

Understanding the Basics: What is Print Lamination?

In commercial printing, lamination involves bonding a thin plastic film (typically polypropylene or polyester) to the printed paper surface using heat and pressure. This process adds rigidity, water resistance, and tear strength.

- Gloss Lamination: A shiny, reflective finish that enhances color saturation and contrast. It is the industry standard for textbooks, flyers, and children’s books.

- Soft Touch Lamination: A specialty matte finish (often called "velvet" lamination) that offers a unique tactile experience. It has no shine and feels akin to short-nap velvet or soft peach skin.

1. Visual Impact and Color Vibrancy

The interaction between the laminate film and the underlying ink is the primary driver for visual aesthetics.

Gloss: Maximum Vibrancy

Gloss lamination acts like a varnish that deepens blacks and makes colors pop. It reflects light, which draws the eye to images and high-contrast designs. If your artwork relies on photography, vibrant gradients, or needs to stand out on a crowded retail shelf, gloss is often the safer choice.

Soft Touch: Sophisticated Elegance

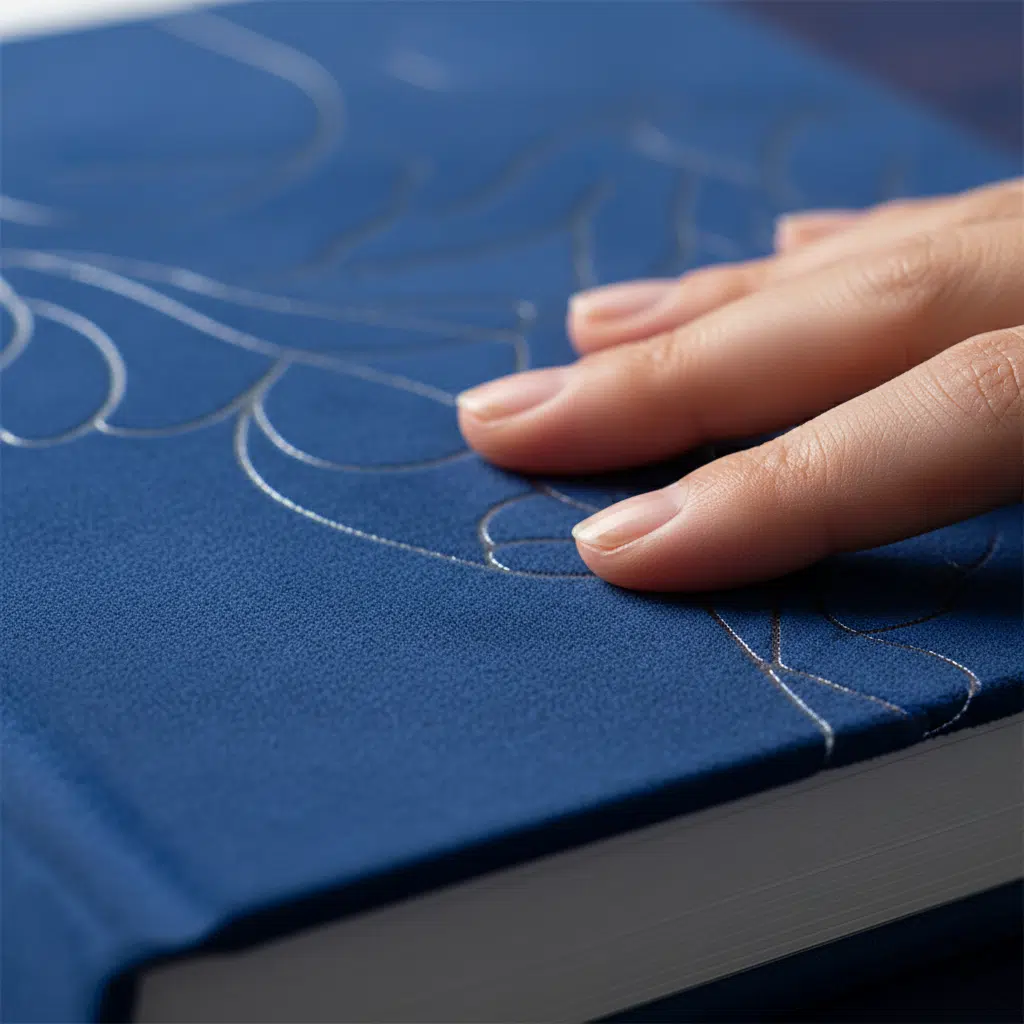

Soft touch is a type of matte lamination. Like standard matte, it diffuses light rather than reflecting it. This can slightly "flatten" the color palette, reducing contrast but creating a sophisticated, muted look. It is highly favored for art books, luxury corporate reports, and high-end packaging where the goal is understated elegance rather than shouting for attention.

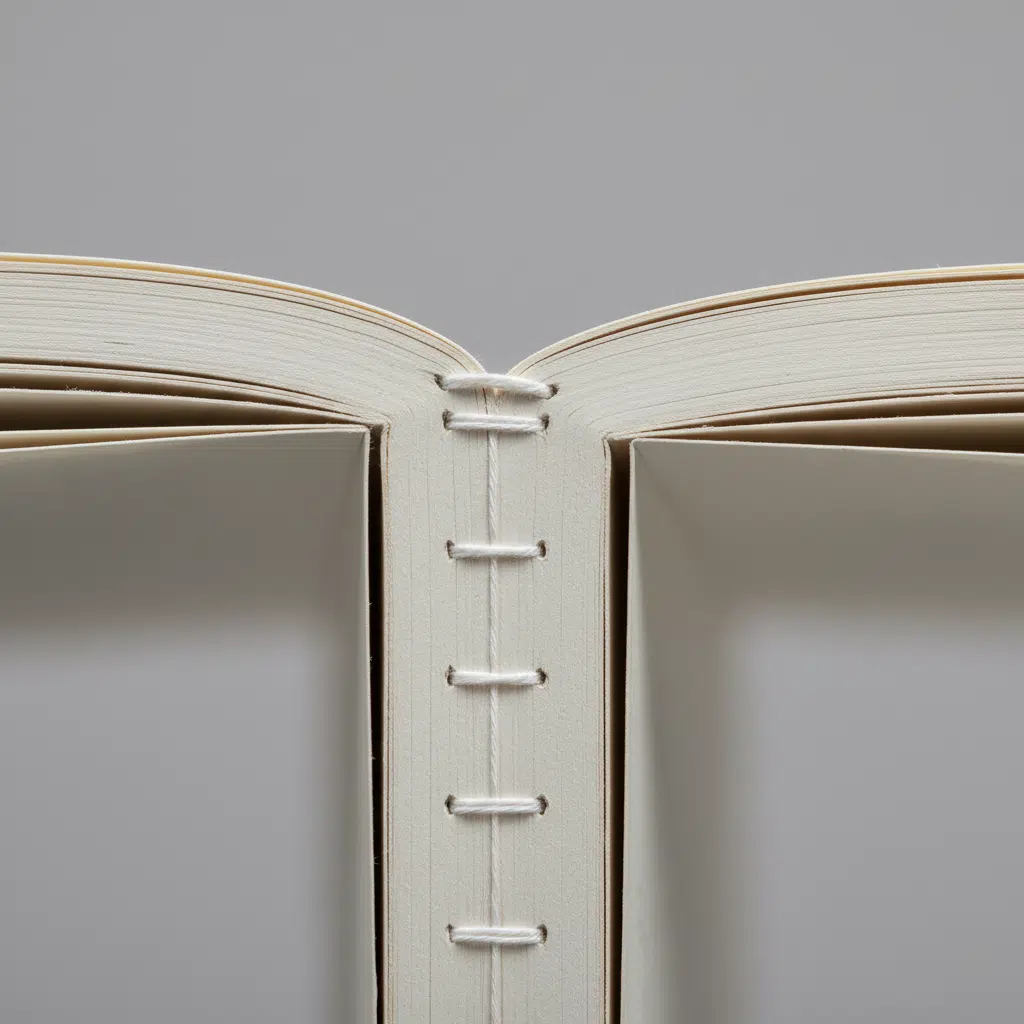

2. Tactile Experience: The "Feel" Factor

In the B2B context, particularly for luxury packaging and coffee table books, the tactile experience is a crucial differentiator.

Soft Touch is engineered specifically for touch. The bi-oriented polypropylene (BOPP) film used in soft touch lamination has a special coating that creates a velvety friction. When a customer picks up a soft-touch book, the perceived value immediately increases. It implies luxury and exclusivity.

Gloss feels slick and smooth. It is functional and familiar. While it doesn’t offer a "premium" tactile surprise, its smoothness is associated with cleanliness and durability.

3. Durability and Scuff Resistance

For items that will be handled frequently—such as training manuals, menus, or school yearbooks—durability is the priority.

Scratch and Scuff Resistance

- Gloss Lamination: Extremely durable. The slick surface deflects scratches well, and because it reflects light, minor micro-scratches are often hidden by the shine. It wipes clean easily.

- Soft Touch Lamination: While standard matte films are notorious for showing scuffs, high-quality soft touch films are generally more resistant to scratches than standard matte. However, they are not invincible. Heavy handling can eventually smooth out the texture in high-contact areas.

The Fingerprint Issue

This is a critical consideration for dark covers (black, navy, deep red).

- Gloss: Shows fingerprints readily, but they are easy to wipe off.

- Soft Touch: Standard matte finishes show oily fingerprints aggressively. However, premium soft touch films are often treated to be fingerprint-resistant. Despite this, on solid black backgrounds, oils from hands can still be visible over time.

4. Production and Cost Considerations

When calculating the unit cost for a large production run, the finish can impact the budget.

Cost Implications

Soft touch is a specialty film. It typically costs more than standard gloss or matte lamination—often ranging from 10% to 25% higher depending on the specific film brand and supplier volume. For massive runs (e.g., 50,000+ units), this cost difference becomes significant. For smaller runs or luxury items, the increase in perceived value usually outweighs the raw material cost.

Post-Print Effects (Spot UV and Foil)

If your design includes UV directo (a glossy clear coat over specific areas) or Hot Foil Stamping, the substrate matters.

- Best Combination: Soft Touch Lamination + Spot UV. The contrast between the ultra-matte velvet background and the high-gloss UV coating creates a stunning visual and tactile effect. This is a top trend in book cover design.

- Standard Combo: Gloss Lamination + Spot UV is rarely done because there is insufficient contrast between the gloss laminate and the gloss UV.

Comparison Summary: At a Glance

| Característica | Laminación brillante | Soft Touch Lamination |

|---|---|---|

| Visual Finish | High shine, reflective, vibrant colors | Ultra-matte, non-reflective, muted elegance |

| Tactile Feel | Slick, smooth, glass-like | Velvety, soft, peach-skin texture |

| Scuff Resistance | High (hides scratches well) | Moderate to High (better than standard matte) |

| Fingerprints | Visible but wipes off easily | Resistant, but oils can show on dark colors |

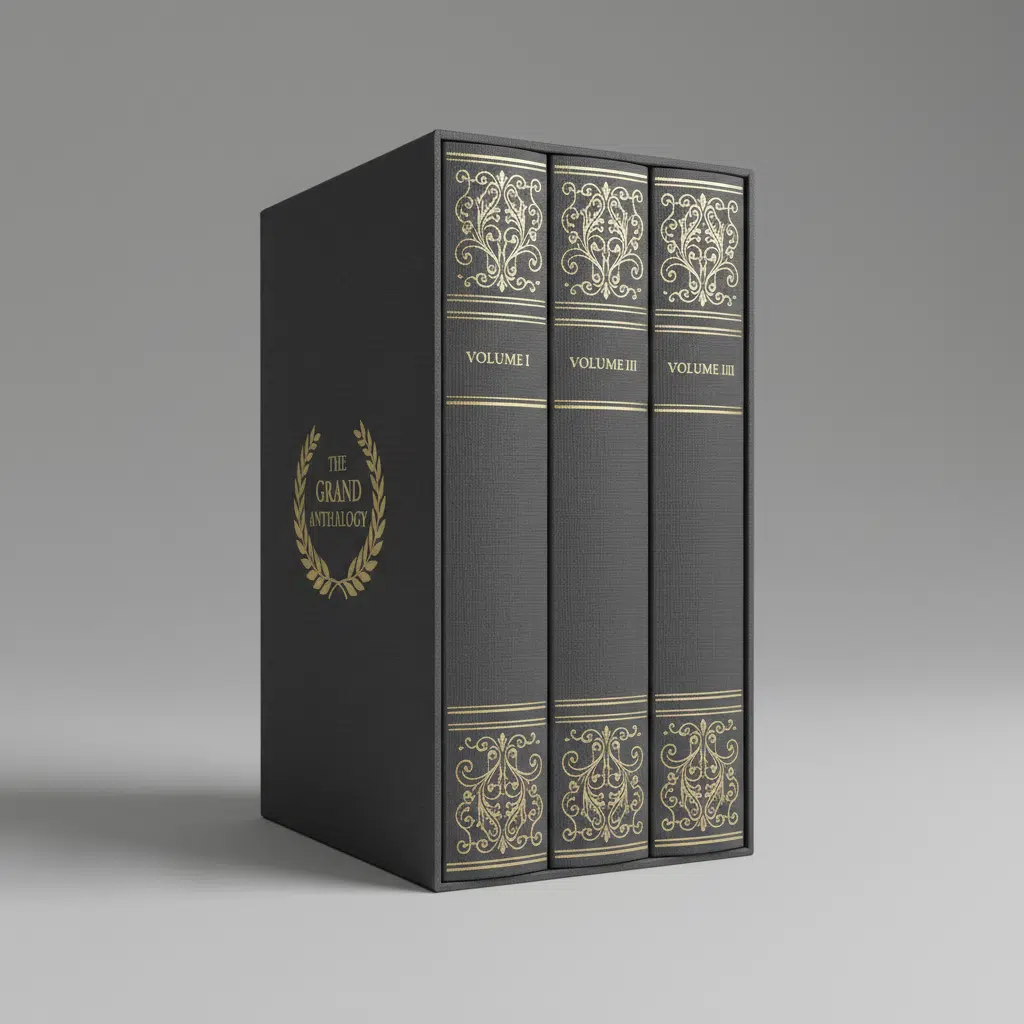

| Best for | Textbooks, flyers, children’s books | Luxury packaging, art books, novels |

| Cost | Standard / Economical | Premium (higher cost) |

Buying Guide: Which Should You Choose?

Choose Gloss Lamination if:

- Durability is #1: The item will be thrown in backpacks, used in kitchens, or handled by children.

- Budget is tight: You need the most economical protection for a large print run.

- Colors need to pop: Your design uses bright, neon, or highly saturated photography.

Choose Soft Touch Lamination if:

- First impressions matter: You are selling a premium product, and the unboxing experience is part of the brand promise.

- You are using special finishes: You plan to use Spot UV or foil stamping to create contrast.

- Glare is an issue: The product will be read under bright lights (e.g., a museum guide or luxury catalog) where reflection makes text hard to read.

FAQs About Print Lamination

Can soft touch lamination be applied to both sides of the sheet?

Yes, soft touch can be applied to one or both sides (duplex). For book covers, it is typically applied only to the outer side, while the inside remains uncoated or standard sealed.

Is soft touch the same as matte lamination?

No. Standard matte lamination lacks the "velvet" tactile property. Soft touch is a specific type of matte film with a tactile coating. It feels physically different, whereas standard matte just feels like smooth paper.

Does lamination affect the recycling of the book?

Most modern laminates are plastic-based (BOPP). While technically recyclable in specialized facilities, lamination can complicate standard paper recycling streams. However, biodegradable cellulose-based laminates are becoming available. Ask your printer about eco-friendly lamination options if sustainability is a priority.

Ready to Start Your Print Project?

Choosing between gloss and soft touch lamination depends on the balance between durability, aesthetics, and budget. At YBJ Printing, we specialize in high-quality offset printing and finishing services for global clients.

Not sure which finish is right for your brand? Contact our team today to discuss your specifications or request a sample kit to feel the difference yourself.