Maximizing Value with Split-Run Manufacturing

For publishers, Kickstarter creators, and brand owners, the demand for exclusive content is higher than ever. Collectors and backers often seek "Deluxe" or "Limited Edition" versions of art books, RPG manuals, and graphic novels. However, producing two completely separate print runs—one for the standard edition and one for the premium edition—can be prohibitively expensive due to doubling up on setup costs.

The solution lies in split-run book printing. This manufacturing strategy allows you to produce a high volume of identical interior text blocks while differentiating the final product through cover materials, binding styles, or packaging. By leveraging economies of scale on the interior printing while customizing the exterior, you can offer tiered products at a fraction of the cost of two independent production runs.

This guide outlines the technical strategies for executing a successful split run, ensuring high-quality results for both standard and deluxe editions.

The Core Concept: Shared Interiors, Divergent Exteriors

In offset printing, the most significant upfront costs are the "make-ready" and plate creation for the interior pages (the text block). If you are printing 1,000 copies, the press runs most efficiently if the interior content remains static.

In a split run, the factory prints the interior signatures for the total quantity (e.g., 2,000 units) in one continuous pass. The differentiation occurs during the binding and finishing stages. The production line is paused to change cover materials or casing-in settings, allowing you to split the total volume into different variations, such as:

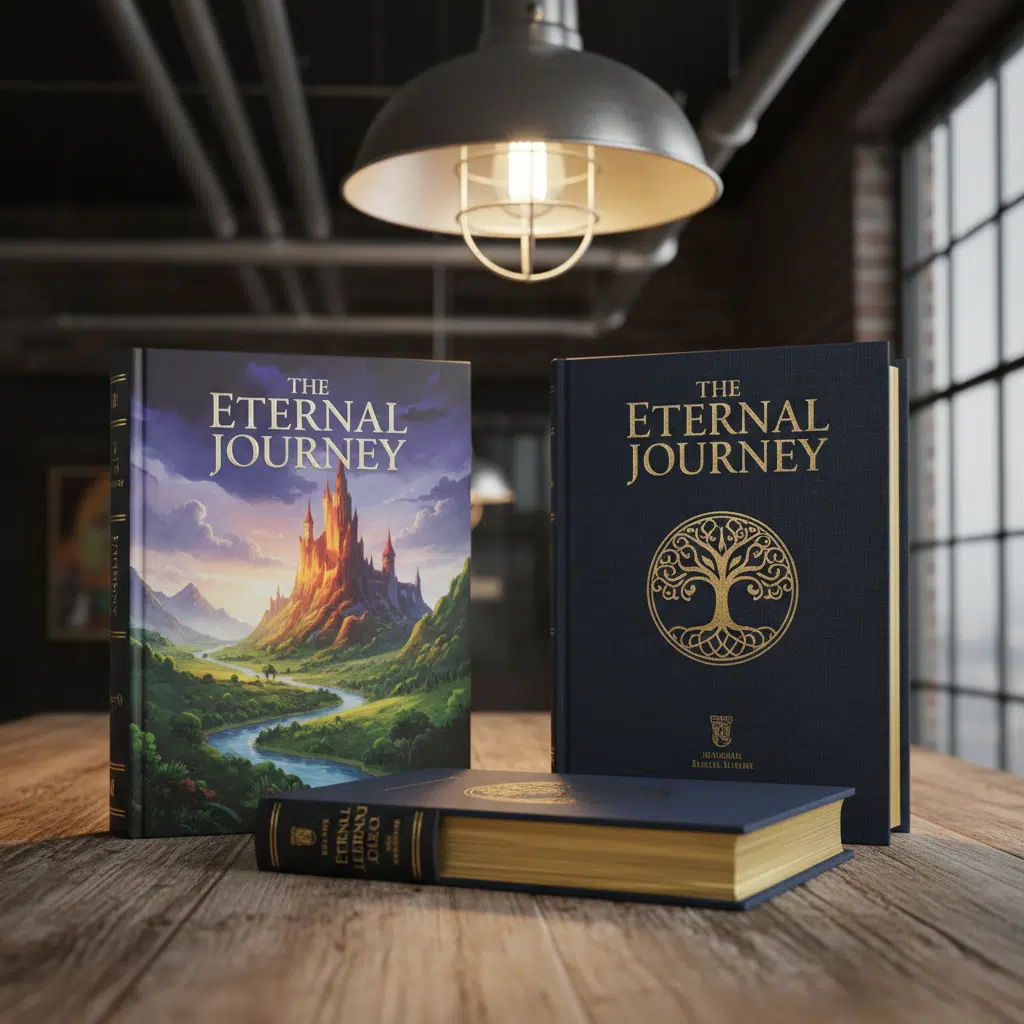

- Standard Edition (1,500 units): Printed paper case (PPC) with gloss lamination.

- Deluxe Edition (500 units): Cloth binding with gold foil stamping and a dust jacket.

Strategic Differentiation Methods

To create a high-value limited edition without altering the expensive interior plates, consider the following manufacturing upgrades.

1. Cover Material Variance

Changing the cover material is the most common method for split runs. While the interior block remains the same, the "case" (hardcover) can be swapped.

- Standard: 157gsm art paper wrapped over 2.5mm greyboard (Printed Paper Case).

- Deluxe: PU leather, linen cloth, or bonded leather wrapped over the same board thickness. This often requires a separate foil stamping die for the title, as ink printing is rarely used on cloth.

2. Dust Jackets and Belly Bands

A cost-effective way to differentiate editions is to use the same hardcover binding for all copies but apply different dust jackets. Alternatively, the deluxe edition might receive a dust jacket while the standard does not. Special finishes like Spot UV, embossing, or soft-touch lamination on the deluxe jacket add perceived value.

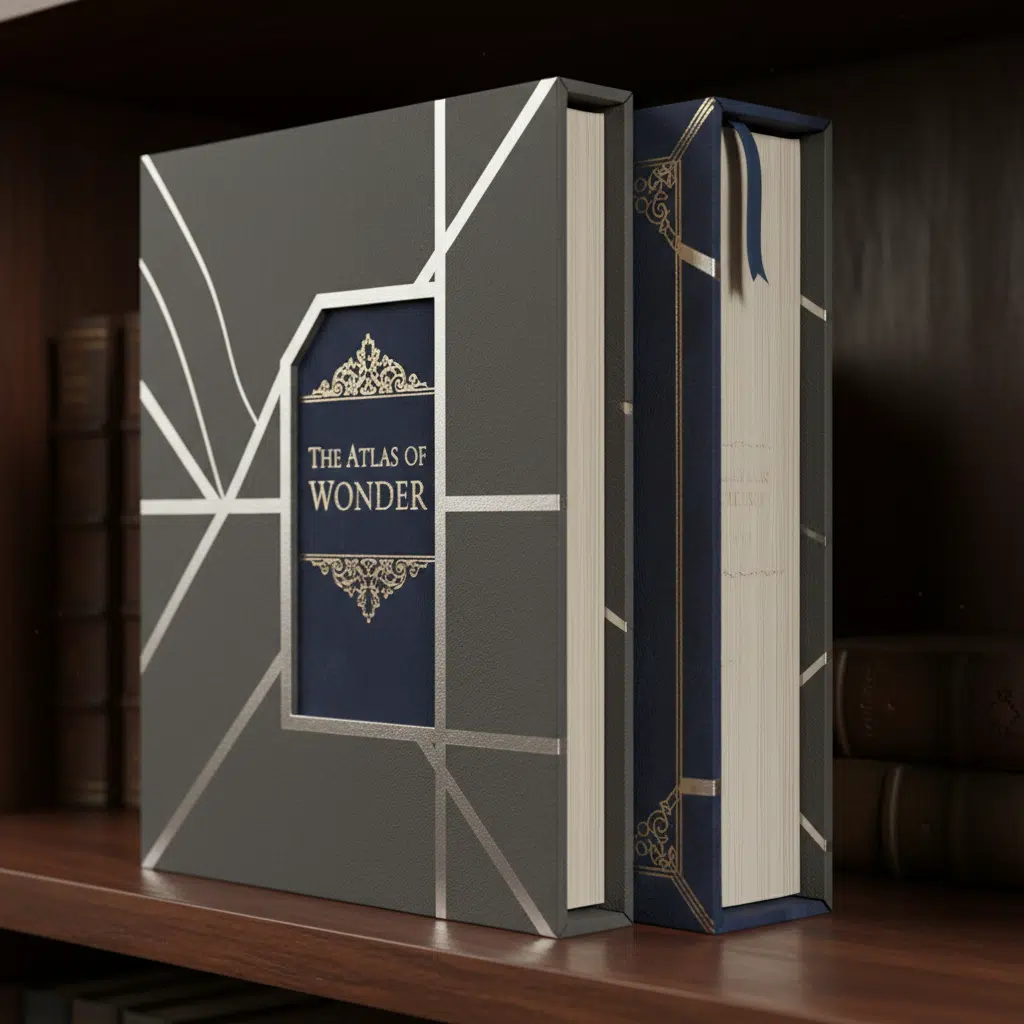

3. Custom Slipcases and Clamshell Boxes

Adding a structural element is a powerful way to justify a higher price point. You can manufacture the books identically, but package the limited edition portion inside a custom slipcase or clamshell box. This protects the book and offers a larger canvas for artwork. Since the box is an external component, it does not interfere with the high-speed binding of the book blocks.

4. Endpapers and Tip-in Sheets

Guardas: The sheets gluing the text block to the cover can be changed during the binding process. Standard copies might use plain white wood-free paper, while deluxe copies use printed artwork or textured colored stock. Note that this requires stopping the binding line to swap the endpaper rolls or stacks.

Tip-in Sheets: For signed limited editions, a "tip-in" page (often signed by the author) can be glued into the front of the deluxe text blocks before binding. This allows the author to sign loose sheets rather than shipping heavy books back and forth.

5. Edge Finishing

Sprayed edges (coloring the edges of the book block) or gilding (applying foil to the edges) are premium features. You can apply these finishes only to the limited edition batch. For example, the standard edition has plain edges, while the deluxe edition features metallic gold edges.

Technical & Cost Considerations

While split runs save money compared to two separate orders, they do introduce specific costs and constraints.

| Cost Factor | Explanation |

|---|---|

| Changeover Fees | The factory charges a fee to stop the machine, wash up (if changing ink), and swap materials (e.g., switching from printed covers to cloth). |

| MOQ Per Version | While the total run might be 1,000, binding lines often have a minimum efficiency threshold. A split of 950/50 is harder to manage than 800/200 due to material waste during setup. |

| Die Costs | If the deluxe version uses foil stamping on cloth, you must pay for the metal die mold. The standard version (printed) does not require this. |

| Assembly Time | Manual tasks like inserting books into slipcases or applying belly bands will increase labor costs for the deluxe portion. |

Cantidades mínimas de pedido (CMP)

In offset printing, the typical MOQ is often 500 or 1,000 units. For split runs, manufacturers usually require a minimum per variation to cover the setup waste. For example, a manufacturer might require at least 200–300 units for the "Deluxe" variation to ensure the binding line runs smoothly. Always confirm the specific minimums for binding variations with your account manager.

Buying Guide: How to Request a Split Run

When requesting a quote for a split run project, clarity is essential to avoid pricing errors. Use the following checklist when communicating with your printing partner:

- Total Quantity: State the aggregate number (e.g., "Total 2,000 books").

- The Split: Clearly define the breakdown (e.g., "1,500 Standard / 500 Deluxe").

- Shared Specs: List the specifications that remain constant (Trim size, page count, paper stock, interior printing colors).

- Divergent Specs: Create a separate section detailing the differences.

Example: “Standard Cover: 157gsm gloss art paper. Deluxe Cover: Black linen cloth with gold foil.” - Packaging: Specify if the deluxe version requires shrink-wrapping individually or insertion into a slipcase.

Preguntas frecuentes (FAQ)

Can I change the content of the book for the limited edition?

Technically, yes, but it negates the main cost benefit. Changing the interior text or images requires making new printing plates for those pages. If you want to add content to a deluxe edition without re-plating the whole book, consider adding a separate 8-page or 16-page signature at the end of the book, or using a tip-in sheet.

Is a split run cheaper than Digital (POD) printing for the limited edition?

If the limited edition quantity is very low (e.g., under 100 copies), digital printing might be cheaper upfront, but the quality of binding and finishing (like foil stamping or cloth) is often restricted in digital workflows. For runs over 200–300 units, a split offset run usually offers better unit pricing and superior quality.

Does a split run increase production time?

Slightly. The sourcing of different cover materials (especially specialized cloth or leather) can add lead time. Additionally, the bindery must perform two distinct setups. However, since the interior printing happens simultaneously, it is faster than scheduling two completely separate production slots.

Can I use different paper weights for the interior in a split run?

No. The interior paper runs through the press in one batch. To use different paper, the printer would have to stop the press, change paper rolls/pallets, and make-ready again, which is essentially treated as two separate orders.

Start Your Custom Project

Split-run printing is the smart way to diversify your product offering and increase revenue without doubling your investment. Whether you are fulfilling a Kickstarter campaign or stocking a corporate gift shop, we can guide you through the material options and technical specifications.

Ready to explore your options?