Interactive Print: More Than Just Ink on Paper

For publishers and brand owners, the transition from static board books to interactive sound books represents a significant leap in product value—and manufacturing complexity. Adding audio components transforms a standard reading experience into a sensory one, but it also introduces electronic assembly, battery safety compliance, and precise die-cutting requirements into the production workflow.

This guide addresses the technical and operational realities of manufacturing children’s sound books. We explore the structural integration of sound modules, the differences between activation mechanisms, and the critical safety standards required for international distribution.

Types of Sound Modules and Activation Mechanisms

Selecting the right module is the first step in the engineering process. The choice impacts the book’s thickness, layout, and user experience. Most industrial sound book projects utilize one of two primary technologies.

1. Push-Button Modules (Membrane Switches)

This is the most common mechanism for children’s board books. A carbon pill or metal dome switch is embedded beneath the paper or within a plastic housing.

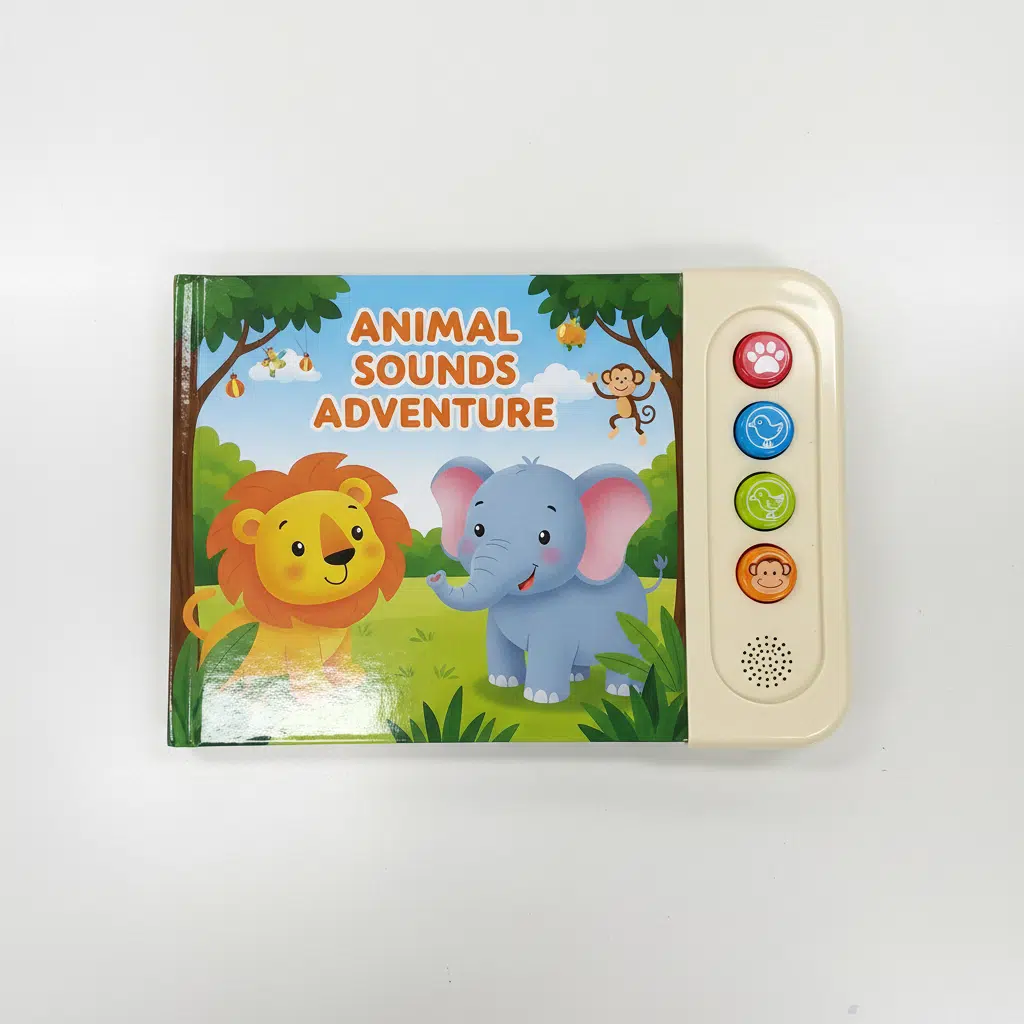

- Side-Panel / Piano Style: The sound module is housed in a visible plastic casing attached to the side or bottom of the book. Buttons are distinct and easy for toddlers to press. This is cost-effective as it requires less complex die-cutting of the book block itself.

- Embedded / Page-Triggered: The mechanism is hidden between layers of board. The reader presses a specific icon on the page to trigger the sound. This requires precise alignment between the printed artwork, the die-cut hole in the board, and the underlying membrane switch.

2. Light Sensor (Photosensitive) Modules

Light sensors are often used in higher-end or novelty books. The sensor is concealed within the spine or a die-cut aperture. When a page is turned, ambient light hits the sensor, triggering the audio file associated with that spread.

- Pros: Creates a magical, seamless experience with no visible buttons.

- Contras: Requires consistent ambient light to function; manufacturing requires extremely tight tolerances to ensure the sensor is not triggered accidentally while the book is closed.

Technical Specifications for Audio Integration

Successful production relies on high-quality source files and appropriate hardware selection.

Audio Duration and Quality

Sound chips vary by memory capacity, typically measured in seconds (e.g., 6s, 12s, 30s, or up to several minutes). Longer audio requires larger memory chips, which impacts unit cost.

- Format: Manufacturers usually require high-fidelity WAV or MP3 files.

- Sampling Rate: Standard toys often use lower sampling rates to save memory, but for educational books (e.g., language learning), a higher sample rate is necessary for clarity.

- Volume Control: Decibel levels must be calibrated to be audible but safe for children’s ears, adhering to standards like EN71.

Speaker and Housing

The speaker size (typically 27mm, 29mm, or 40mm) determines volume and bass response. The plastic housing must be engineered to amplify sound without rattling. For board books, the module is often glued into a die-cut cavity in the back cover, requiring the book block to be thick enough to flush-mount the casing.

Battery Safety and Compliance Standards

Safety is the non-negotiable aspect of sound book manufacturing. Because these products contain small parts (batteries) and are marketed to children, they face strict scrutiny from customs and safety regulators (CPSC, EU standards).

Battery Compartment Security

To prevent ingestion hazards, the battery compartment must be secured with a screw that cannot be removed by a child. Snap-fit covers are generally not compliant for products intended for children under three years old.

Insulation Tabs (Pull-Tabs)

To preserve battery life during shipping and warehousing, a plastic insulation tab is inserted into the circuit to break the connection. This tab is removed by the consumer upon first use. During assembly, ensuring these tabs are correctly inserted is a critical QC checkpoint.

Certification Requirements

Publishers must ensure their manufacturing partner can provide products compliant with:

- CE / EN71 (Europe): Covers mechanical properties and migration of certain elements.

- ASTM F963 (EE.UU.): Especificación normalizada de seguridad de los juguetes para los consumidores.

- RoHS/WEEE: Directives regarding hazardous substances in electronic equipment and waste disposal.

The Manufacturing Workflow

Integrating electronics into paper products changes the traditional binding process.

1. Printing and Die-Cutting

The paperboard is printed and laminated first. Unlike standard books, sound books require complex die-cutting to create cavities for the module and holes for sound to escape (speaker grilles). Precision is vital; a misalignment of 1mm can block a sensor or cover a button.

2. Module Assembly

Sound modules are typically pre-assembled and tested before reaching the bindery line. They are programmed with the client’s audio files and inspected for sound clarity.

3. Mounting and Adhesion

The module is adhered to the book block. For embedded modules, this happens layer by layer. For external housings, the module is glued to the extended back cover. Industrial-grade adhesives are used to ensure the module does not detach during drop tests.

Quality Assurance (QA) Protocols

Defect rates in electronic print products can be higher than standard books if rigorous QA isn’t applied. A robust inspection process includes:

- Function Testing: Every single unit (100% check) is typically tested to ensure all buttons trigger the correct sounds.

- Drop Testing: Random samples are dropped from standard heights to ensure the housing doesn’t crack and the battery compartment remains secure.

- Life-Cycle Testing: ensuring buttons can withstand thousands of presses without failure.

Buying Guide: Preparing for Production

When requesting a quote for sound books, specific details allow manufacturers to provide accurate pricing and timelines.

Key Information Needed

- Trim Size & Extent: Dimensions of the book and number of pages.

- Module Type: Piano, embedded button, or light sensor.

- Number of Sounds: How many distinct buttons/triggers?

- Total Audio Duration: The sum of all sound clips in seconds.

- Order Quantity (MOQ): Electronic components often carry higher MOQs (typically 3,000–5,000 units) due to chip programming and mold setup costs.

Prototyping

Before mass production, request a “white dummy” with the electronic module functioning. This allows you to verify the button pressure, sound volume, and physical feel of the book before artwork is applied.

Preguntas frecuentes

Can I change the batteries in sound books?

Yes, most high-quality sound books feature replaceable batteries (usually AG10/LR1130 or AAA), accessible via a screw-locked compartment on the back cover.

What is the typical lead time for sound books?

Lead times are longer than standard books due to the sourcing of electronic chips. Expect 4–6 weeks for the electronic components and another 4 weeks for printing and assembly, totaling 8–10 weeks post-proof approval.

Do I need to provide the sound files?

Yes, the client provides the final audio files. The manufacturer then programs these onto the chips. It is recommended to provide files at a higher quality than required; the factory engineers will compress them to fit the chip’s memory while optimizing clarity.

How do you ensure the buttons aren’t too hard for children to press?

This is determined by the “activation force” of the membrane switch. Experienced manufacturers calibrate this specifically for children’s products. Testing a physical sample is the best way to verify this.

Ready to bring your interactive book project to life? Contact our team today to discuss specifications, request a sound module sample, or get a custom quote for your next manufacturing run.