Meeting the Global Demand for Green Supply Chains

For global brands, sustainability is no longer just a marketing buzzword—it is a critical component of supply chain management and corporate responsibility. As consumers and regulators in the EU and US increasingly demand transparency, procurement teams face the challenge of sourcing printed materials that align with strict environmental standards without compromising on quality or cost-efficiency.

Transitioning to sustainable printing involves more than just choosing recycled paper. It requires a holistic approach to materials, chemical safety, and manufacturing processes. Whether you are producing packaging, marketing collateral, or hardcover books, understanding the technical specifications of eco-friendly printing is essential for maintaining brand integrity and meeting international compliance requirements.

Core Materials: Paper, Ink, and Adhesives

The foundation of any sustainable print project lies in the raw materials. For B2B buyers, the goal is to balance environmental impact with printability and durability.

FSC-Certified and Recycled Papers

Paper sourcing is the most significant variable in the carbon footprint of a print job. There are two primary categories to consider:

- FSC-Certified Paper: The Forest Stewardship Council (FSC) certifies that wood pulp comes from responsibly managed forests. This is crucial for brands exporting to markets with strict timber regulations.

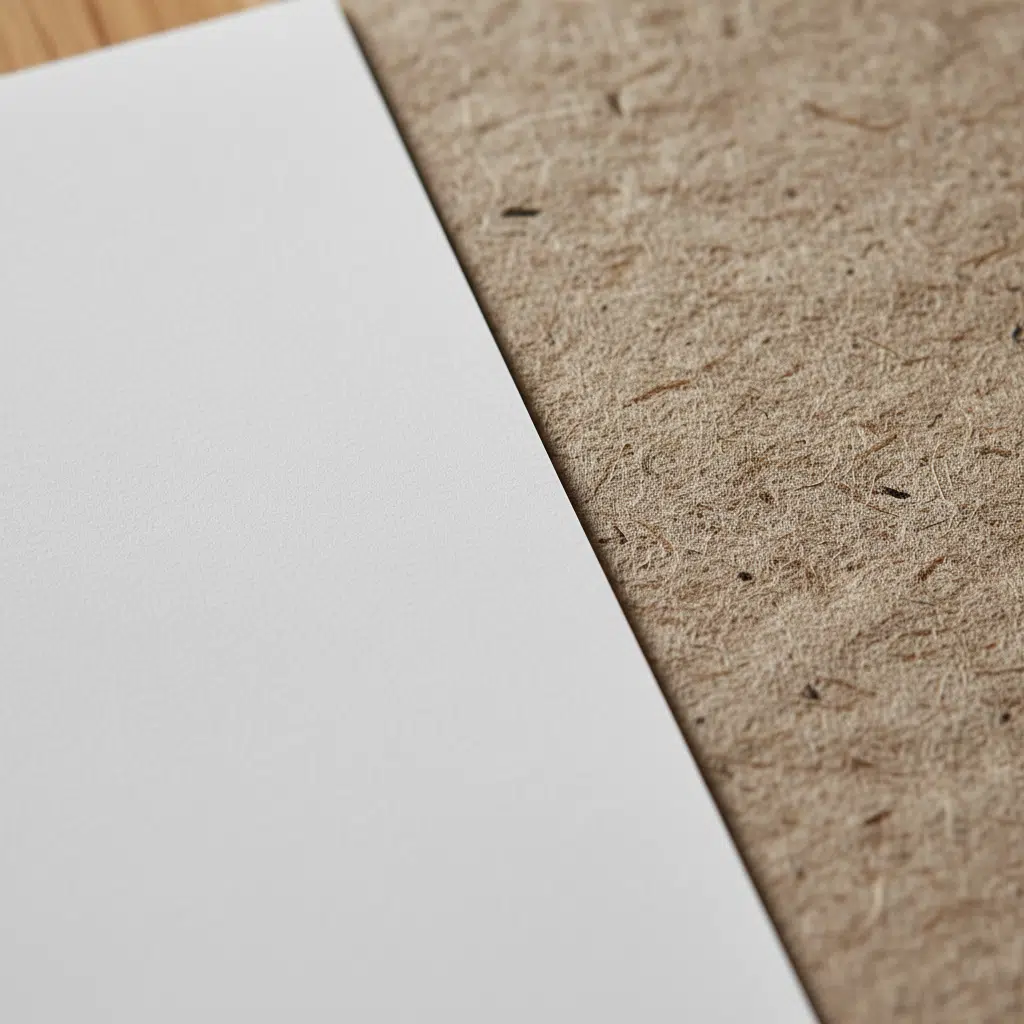

- Post-Consumer Waste (PCW) Recycled Paper: This paper is made from waste paper that has been used and recycled. While 100% PCW offers the highest environmental benefit, it may have a slightly different texture or brightness compared to virgin fiber.

For a deeper dive into how these substrates affect the final product, reading about <a href="Exploring the Benefits of Eco-Friendly Paper for Book Printing“>eco-friendly paper options for book printing can provide specific insights into texture and opacity trade-offs.

Vegetable and Soy-Based Inks

Traditional petroleum-based inks often contain high levels of Volatile Organic Compounds (VOCs), which can be harmful to both the environment and factory workers. The modern industry standard for sustainable printing is the use of vegetable-based inks, primarily soy ink.

Soy inks offer several technical advantages beyond sustainability:

- Vibrancy: Soy oil is clearer than petroleum oil, often allowing pigments to appear more vibrant.

- Recyclability: Paper printed with soy ink is easier to de-ink during the recycling process, closing the loop on the product lifecycle.

To understand how these inks interact with different substrates, refer to our guide on <a href="Impresión sostenible de libros: Guía del papel ecológico y la tinta de soja“>sustainable book printing and soy ink applications.

Regulatory Compliance for EU and US Markets

When importing printed goods into major Western markets, compliance goes beyond voluntary eco-labels. It often involves strict legal frameworks regarding chemical safety and deforestation.

EU Regulations (REACH and EUDR)

For the European Union, compliance is rigorous. The REACH regulation (Registration, Evaluation, Authorisation and Restriction of Chemicals) restricts the use of certain hazardous substances in manufactured goods, including inks and varnishes. Additionally, the upcoming EU Deforestation Regulation (EUDR) will require operators to prove that products like paper and cardboard do not contribute to deforestation.

US Standards (Lacey Act and CPSIA)

In the United States, the Lacey Act prohibits the import of illegally harvested wood products, making a verified Chain of Custody (like FSC) critical for risk mitigation. Furthermore, if your printed materials are intended for children (e.g., board books or educational kits), they must comply with the Ley de mejora de la seguridad de los productos de consumo (CPSIA), which sets strict limits on lead and phthalates in inks and coatings.

Technical Considerations for Sustainable Printing

Switching to eco-friendly materials may require adjustments to your design and production expectations. Here are key technical factors to discuss with your printer:

Drying Times and Production Speed

Vegetable-based inks rely on oxidation to dry, unlike UV inks which cure instantly, or petroleum inks which dry by evaporation and absorption. This can result in slightly longer drying times, particularly on uncoated, recycled stocks. Buyers should account for this in their lead time planning to avoid smudging or set-off issues during finishing.

Paper Absorbency and Color Management

Recycled papers often have higher absorbency than coated virgin papers. This results in “dot gain,” where ink spreads slightly as it soaks in, potentially darkening images. Experienced printers manage this by adjusting the prepress curves and applying color profiles specifically designed for uncoated or recycled stocks.

Buying Guide: How to Source Sustainable Print

Effectively procuring green printing solutions requires clear communication of specifications. Use this checklist when requesting quotes:

1. Define Your “Green” Criteria

Be specific. Do you require 100% recycled content, or is 30% acceptable to maintain brightness? Do you need the FSC logo printed on the artwork? Defining this early prevents delays.

2. Check Minimum Order Quantities (MOQs)

Standard house stocks are usually available in any quantity. However, specialty eco-papers (e.g., specific textures or high PCW content) may require a custom paper order from the mill, which often comes with a higher MOQ (typically 1 to 3 tons of paper depending on the mill).

3. Request Material Safety Data Sheets (MSDS)

If compliance is a major concern, ask your manufacturing partner for MSDS or test reports for the inks and glues used. This ensures they meet heavy metal restrictions for your target market.

Preguntas frecuentes (FAQ)

Is sustainable printing more expensive?

It can be. While soy inks are now competitively priced, high-quality recycled paper or FSC-certified stocks can carry a premium due to processing costs and market demand. However, optimizing the size of your product to reduce paper waste can often offset these material costs.

Can I use metallic or fluorescent colors in eco-friendly printing?

Yes, but with caveats. Metallic inks contain metal particles that can make the paper harder to recycle. Some brands opt for soy-based Pantone colors that simulate a premium look without the use of metallic pigments.

Does recycled paper look “dirty”?

Not necessarily. While some brands prefer the flecked, natural look of recycled paper to signal sustainability, high-quality recycled stocks are available that are nearly indistinguishable from virgin paper in terms of whiteness and smoothness.

How do I verify the printer’s claims?

Ask for their certification codes (e.g., FSC license code) and verify them on the certifying body’s public database. Reputable printers are transparent about their supply chain documentation.

Partnering for a Greener Future

Implementing sustainable printing solutions is a powerful way to align your physical products with your brand values. By selecting the right materials and partnering with a manufacturer who understands the technical and regulatory landscape, you can produce high-quality print materials that satisfy both your customers and the planet.

Ready to start your sustainable print project? Contact us today to request a quote or ask for a sample kit featuring our eco-friendly paper and ink options.