In hardcover book manufacturing, the difference between a standard product and a premium edition often lies in the details. While the cover art attracts the initial attention, the endpapers (or endsheets) provide the first tactile and visual interaction once the book is opened. For B2B buyers—whether publishers, corporate brand managers, or independent authors—customizing endpapers is a high-impact strategy to elevate perceived value and reinforce structural integrity.

This guide explores the technical and aesthetic considerations of custom endpapers, from material selection to printing techniques, helping you make informed decisions for your next print run.

The Anatomy and Function of Endpapers

Endpapers are not merely decorative; they are a critical structural component of a case-bound (hardcover) book. They consist of a folded sheet of paper glued partially to the inside of the hardcover case and partially to the book block (the inner pages).

Structural Components

- The Paste-Down: The half of the endsheet that is glued completely to the inside of the hardcover board. It hides the raw edges of the cover material and the board itself.

- The Flyleaf: The free-swinging half of the sheet that sits between the cover and the first page of the text block.

Because endpapers serve as the primary hinge connecting the heavy cover to the interior pages, the paper stock used must be durable. Using paper that is too thin or possesses the wrong grain direction can lead to tearing or warping over time.

Material Selection: Choosing the Right Paper Stock

Selecting the correct paper is the first step in endsheet customization. The choice depends on the intended durability, printing method, and budget.

1. Uncoated Woodfree Paper

This is the most common choice for endpapers. Its fibrous, non-reflective surface bonds well with standard binding glues and offers excellent durability.

- Typical Weight: 120gsm to 160gsm.

- Lo mejor para: Novels, journals, and textbooks where durability is key.

- Aesthetics: Provides a classic, organic feel.

2. Coated Art Paper

If your design requires vibrant, full-color imagery (such as maps or photographic patterns), coated paper helps the ink sit on the surface for sharper detail.

- Typical Weight: 128gsm to 157gsm.

- Lo mejor para: Art books, corporate yearbooks, and graphic novels.

- Consideration: Coated papers can be more prone to cracking at the fold if not properly scored, and they may require specific adhesives during binding.

3. Specialty and Textured Papers

For premium special editions, dyed-through stock (paper that is colored during manufacturing rather than printed) offers a rich, uniform look. Textured papers (laid, linen, or felt finishes) add a tactile dimension that implies luxury.

Design and Printing Options

Once the material is selected, the design process determines how the endsheet contributes to the book’s narrative or brand identity.

Solid Colors vs. Printed Colors

There are two ways to achieve a solid color endsheet:

- Dyed Stock: Buying paper that is already manufactured in a specific color. This ensures the edges of the paper are also colored (no white edges) and provides a very deep, consistent hue. However, color options are limited to the paper mill’s catalog.

- Flood Printing (1C): Printing a solid color ink onto white paper. This allows for exact Pantone (PMS) matching, which is crucial for corporate branding.

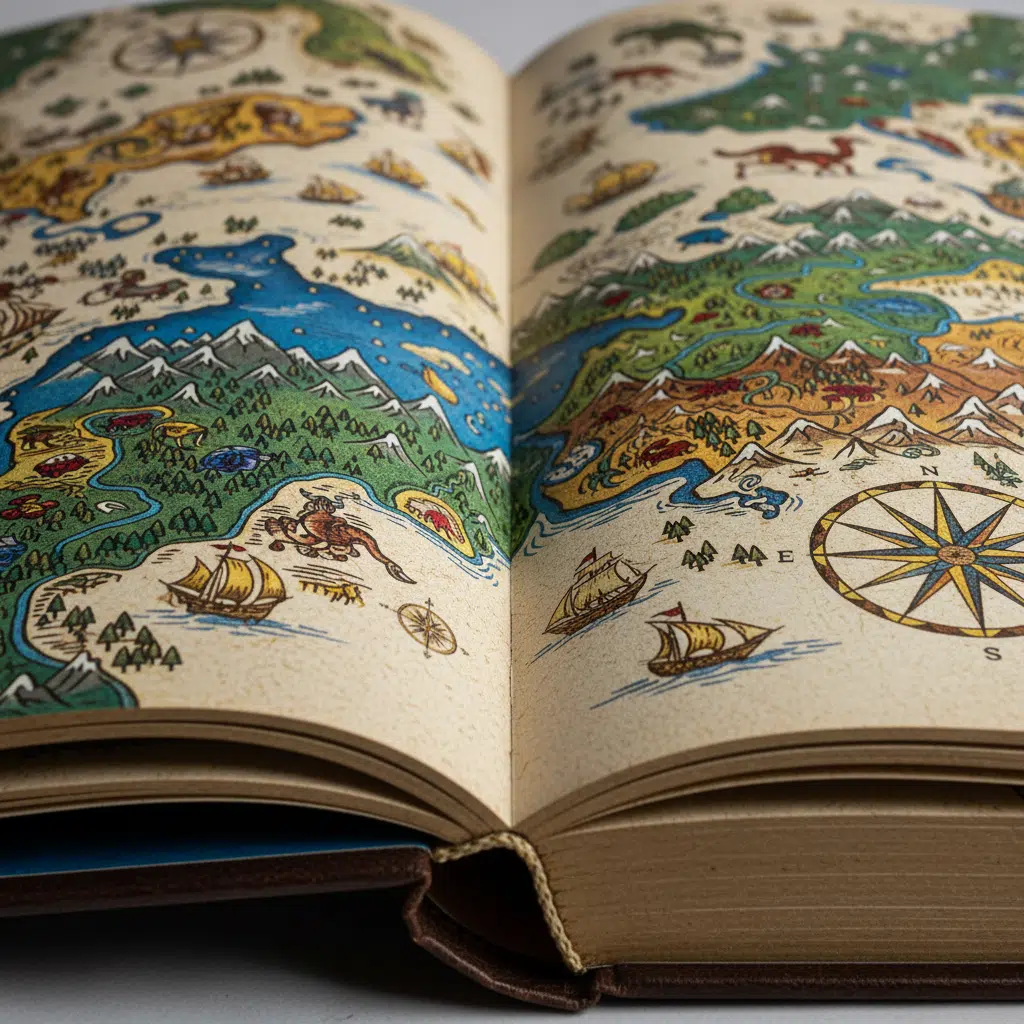

Full-Color (4C) Printing

Printing endsheets in full color (CMYK) transforms unused space into a canvas. Common applications include:

- Maps and Infographics: Essential for fantasy novels or historical non-fiction.

- Repeating Patterns: Logos or thematic motifs that reinforce branding.

- Continuity Designs: Artwork that spans across the paste-down and flyleaf for a panoramic effect.

Technical Manufacturing Considerations

To ensure a high-quality finish, procurement managers and designers must account for specific manufacturing tolerances and requirements.

Dirección del grano

The grain direction of the endpaper is non-negotiable. The grain must run parallel to the spine of the book. If the grain is perpendicular (cross-grain), the paper will fight against the fold, leading to buckling, warping of the cover, or the flyleaf not laying flat when opened. Professional printers will automatically impose this, but it is a vital quality control checkpoint.

Gutter and Bleed

Because part of the endsheet is glued into the spine (the gutter), vital design elements should be kept at least 10–15mm away from the center fold to avoid being lost in the binding. Conversely, background colors and patterns must bleed (extend) beyond the trim edge (typically 3mm to 5mm) to ensure clean edges after trimming.

Glues and Adhesion

The interaction between the paper coating and the adhesive is critical. Heavily coated or varnished papers may repel standard water-based glues. In such cases, printers may need to use stronger hot-melt adhesives or leave specific areas unvarnished (spot varnish) to ensure a secure bond between the endpaper and the greyboard case.

Buying Guide: Ordering Custom Endpapers

When requesting a quote for custom endsheets, clarity on specifications will prevent delays and ensure accurate pricing.

| Factor | Recommendation |

|---|---|

| Paper Weight | Aim for 140gsm. Anything below 120gsm risks tearing; anything above 180gsm may be too stiff for the hinge. |

| Printing Side | Specify if printing is required on one side (facing the reader) or both sides. Note that the side glued to the board is never printed. |

| MOQ (Minimum Order Quantity) | Custom printed endsheets typically become cost-effective at run lengths of 500+ or 1,000+ units due to setup costs. |

| Files | Supply high-resolution PDFs (300 DPI) with bleed included. |

Preguntas frecuentes

Can I use the same paper for endsheets as the interior text pages?

Generally, no. Interior text paper (often 80gsm or 100gsm) is usually too light to support the weight of the hardcover case. Endpapers require a heavier, sturdier stock (120gsm+) to function as a durable hinge.

What is the difference between “self-ended” and separate endsheets?

“Self-ended” means the first and last pages of the text block are glued to the cover. This is common in softcover or lower-cost hardcover binding but is less durable. Separate endsheets are distinct sheets of paper added during binding, offering superior strength and aesthetic flexibility.

Is it more expensive to print on endsheets?

Yes, printing on endsheets adds a step to the production process (printing separate sheets before binding). Using standard white unprinted stock is the most economical option. However, the cost difference is often marginal compared to the increase in perceived product value.

Can I add foil stamping to endpapers?

Yes, foil stamping or spot UV can be applied to endpapers for a luxury finish. This is typically done on the paper before it is trimmed and glued into the book.

Conclusión

Custom printed and colored endpapers are a powerful tool in book manufacturing, bridging the gap between functional necessity and artistic expression. Whether you choose a subtle dyed stock to match a corporate color palette or a vibrant map to immerse readers in a story, the investment in quality endsheets significantly elevates the final product.

Ready to enhance your next hardcover project? Contact our team today to discuss paper options, request samples, or get a quote for your custom specifications.