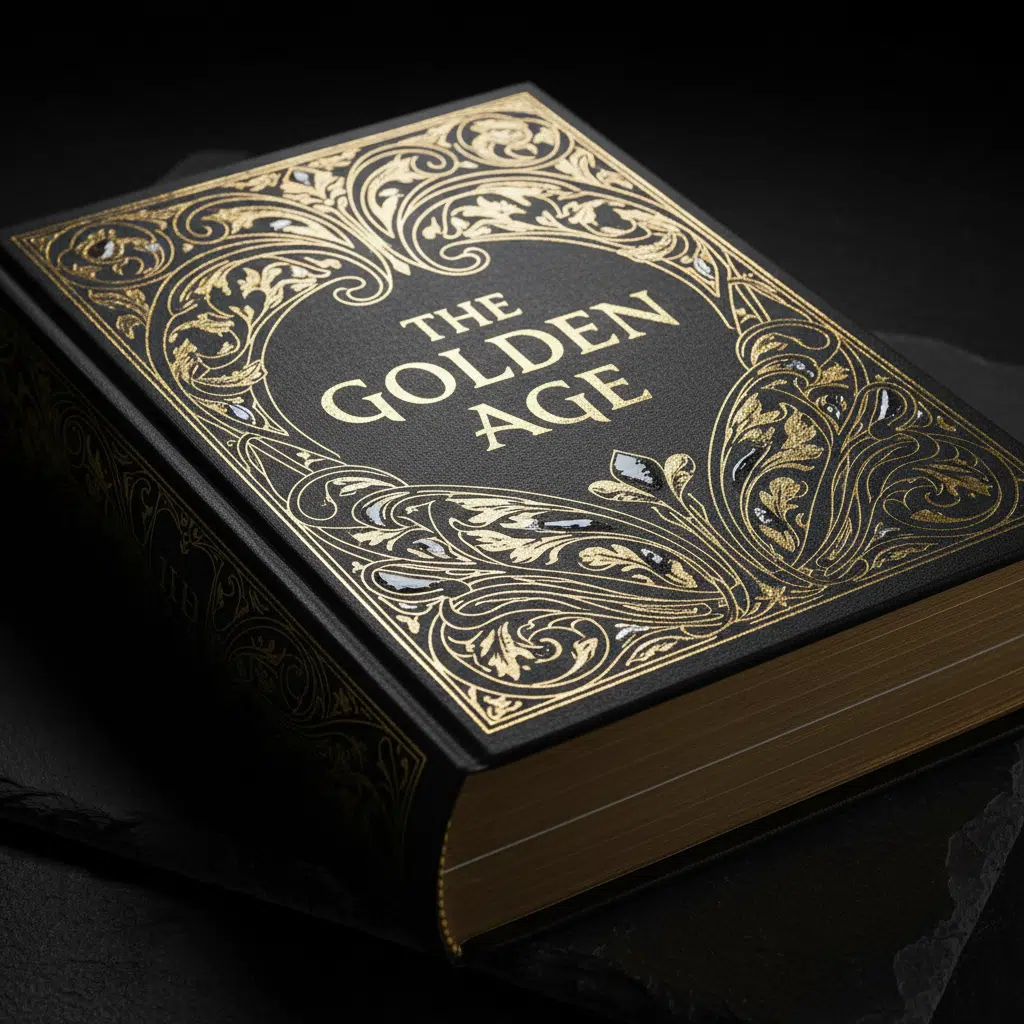

In the competitive world of publishing and retail, a book cover acts as the primary interface between the product and the buyer. For publishers, brand owners, and procurement specialists, selecting the right post-press finishing techniques is not merely an aesthetic choice—it is a strategic investment in perceived value and shelf presence.

While full-color printing lays the visual foundation, tactile finishes like Spot UV, foil stamping, and embossing transform a standard print job into a premium product. These techniques require precise file preparation and an understanding of manufacturing constraints to execute correctly. This guide outlines the technical differences, application best practices, and production considerations for these high-impact custom book finishes.

The Mechanics of Premium Finishes

Understanding how each finish is applied is crucial for determining its suitability for your specific paper stock and design goals.

Spot UV Coating

Spot UV (Ultraviolet) involves applying a clear, high-gloss varnish to specific areas of the cover, which is then cured instantly using UV light. This technique creates a dramatic contrast in texture and sheen.

- Best Application: Applied over matte or soft-touch lamination. The contrast between the velvety matte background and the high-gloss UV area creates a striking visual pop.

- Variations:

- Flat Spot UV: Lies flush with the surface.

- Raised (3D) Spot UV: Uses a thicker layer of varnish to add a tactile, embossed-like feel without modifying the paper fibers.

Estampación

Foil stamping uses heat and pressure to transfer metallic or pigmented foil from a carrier film onto the book cover. Unlike metallic ink, which can appear dull on uncoated stocks, foil sits on top of the paper, providing 100% opacity and true reflectivity.

- Hot Foil Stamping: Requires a custom metal die. It provides the most crisp, durable finish and is ideal for textured stocks.

- Cold Foil: Applied inline during the printing process using adhesive. It is generally faster and allows for gradients, but lacks the slight debossed feel of hot stamping.

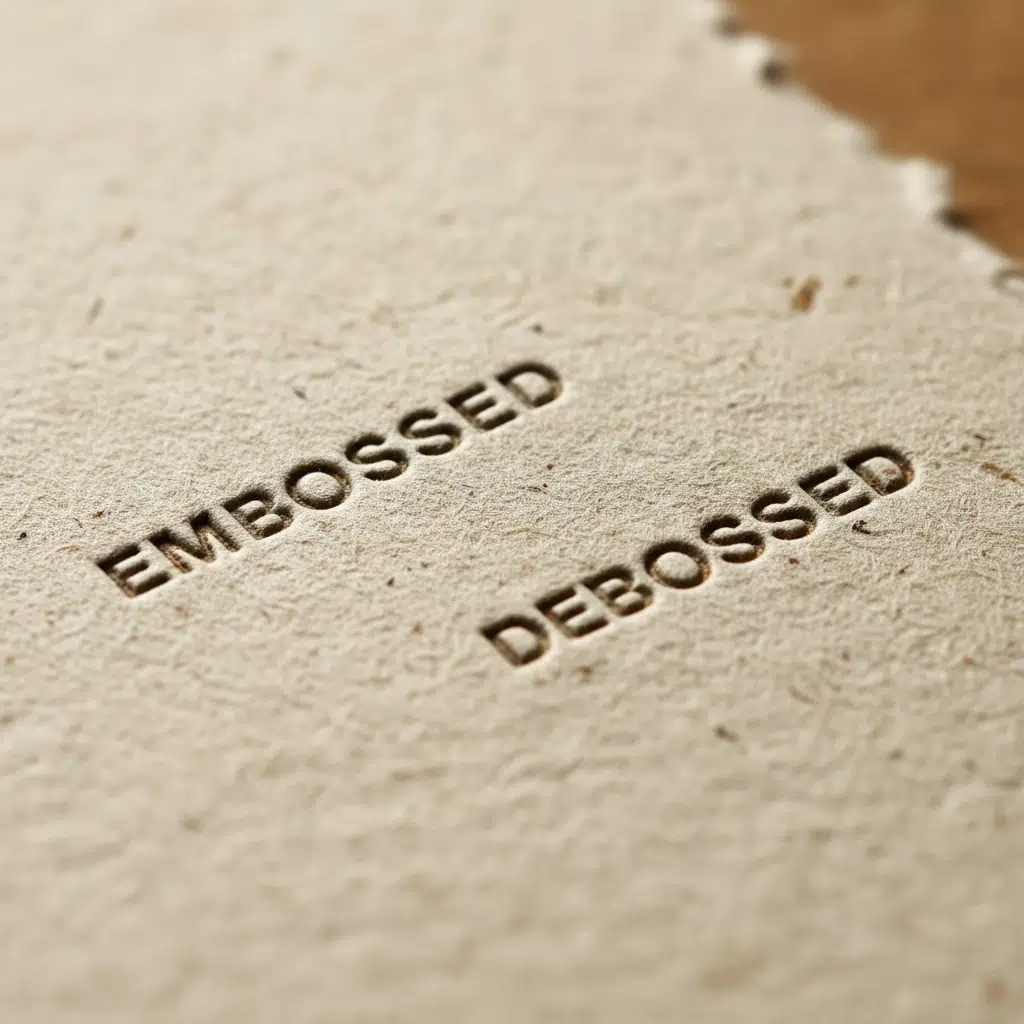

Embossing and Debossing

These processes mechanically reshape the paper stock using male and female dies.

- Embossing: Pushes the paper stock upward, creating a raised relief.

- Debossing: Presses the design downward into the stock, creating an indentation.

- Blind vs. Registered: "Blind" embossing/debossing is applied to unprinted paper for a subtle textural effect. "Registered" aligns the die with a printed element or foil stamp to accentuate a logo or title.

Technical Design & File Preparation

For designers and prepress engineers, the success of these finishes depends heavily on file setup. Improperly prepared files can lead to registration errors, filled-in details, or tooling issues.

Vector Requirements

All finishing elements must be created as vector paths (not raster images) to ensure crisp edges for die-casting or screen creation. Create a separate layer in your design software (e.g., Adobe InDesign or Illustrator) specifically for the finish.

Spot Colors and Overprinting

Assign a custom spot color (often 100% Magenta or Cyan) to the finishing elements to distinguish them from the CMYK artwork. Label this swatch clearly (e.g., "Gold_Foil" or "Spot_UV") and set the attributes to "Overprint" to prevent the underlying artwork from being knocked out during the RIP process.

Minimum Line Weights and Spacing

Physical limitations of dies and screens dictate minimum tolerances:

- Estampación: Avoid lines thinner than 0.25pt. Large solid areas of foil can sometimes blister; incorporating a texture or pattern can help.

- Gofrado/grabado en relieve: Requires slightly thicker lines (0.5pt minimum recommended) to prevent the paper from cracking or tearing under pressure.

- Espaciado: Ensure a minimum gap of 1–2mm between the finish and the trim line or fold to avoid cracking during binding.

Material Compatibility and Lamination

The choice of substrate (paper) and lamination significantly impacts the quality of the finish.

Coated vs. Uncoated Stock

UV directo works best on coated stocks (C1S or C2S). On uncoated paper, the varnish may soak into the fibers, resulting in a dull, uneven look unless a primer is applied first. Foil stamping y gofrado are versatile and perform exceptionally well on both coated and uncoated textured stocks, offering a premium feel on natural papers.

The Role of Lamination

Lamination is almost mandatory for book covers featuring Spot UV or foil to prevent the paper from cracking and to provide a smooth base. Soft-touch lamination is the industry standard for pairing with Spot UV, as the tactile difference between the rubbery matte surface and the slick gloss varnish maximizes the effect.

Manufacturing and Cost Considerations

When budgeting for custom book finishes, consider the following production factors:

Tooling Costs

Foil stamping and embossing require the fabrication of metal dies (magnesium, copper, or brass). This is a one-time setup cost. If you plan to reprint the book later, the dies can often be reused, reducing the cost of subsequent runs. Spot UV typically uses screens or digital print heads, which have lower setup costs compared to metal dies.

Registration Tolerances

No manufacturing process is perfect. Standard registration tolerance is typically ±0.5mm to ±1mm. Designers should avoid tight registration where a foil outline must perfectly trace small text, as slight shifts during the print run can be noticeable. "Blind" techniques or designs with generous bleed allowances are safer for mass production.

MOQ (Cantidad mínima de pedido)

Due to the setup times involved in calibrating dies and UV stations, these finishes are most cost-effective for runs of 500 to 1,000 units or more. For ultra-short runs (e.g., 50 copies), digital foiling or digital varnish options exist but may differ in quality from traditional offset methods.

Buying Guide: Ordering Custom Book Covers

To ensure your project proceeds smoothly, address the following during the procurement phase:

- Request Material Samples: Before committing, ask for a sample book or swatches of the specific foil color and paper stock. Photos often fail to capture the true reflectivity of foil or the depth of embossing.

- Proofing Limitations: Creating a single "wet proof" with actual foil and embossing is prohibitively expensive because it requires full production setup. Most printers provide a digital PDF proof for layout and a separate material sample for finish reference.

- Specify Direction: For embossing, clearly state if you want the image raised (emboss) or recessed (deboss). Confusion here is a common source of error.

Preguntas frecuentes

Can I combine Spot UV and Foil Stamping on the same cover?

Yes, combining these effects creates a highly luxurious look. However, they should generally not overlap directly unless tested, as the UV varnish may not adhere well to the foil surface. It is safer to keep them as separate design elements.

Does embossing affect the inside of the book cover?

Yes. Standard embossing pushes the paper up, leaving a debossed (indented) reverse image on the other side. If the cover is a paperback (softcover), this will be visible on the inside cover. For hardcovers (case bound), the board prevents this from showing through to the endpapers.

What is the difference between blind embossing and foil embossing?

Blind embossing uses no ink or foil; it relies entirely on light and shadow created by the relief. Foil embossing (combination stamping) applies foil and embosses the paper simultaneously, creating a raised, metallic 3D effect.

Is Spot UV durable?

Standard Spot UV is durable but can crack if placed directly over a fold line or spine. It is best kept to flat areas of the front or back cover.

Ready to Elevate Your Book Projects?

High-quality finishing transforms a book from a simple document into a premium asset. Whether you need the subtle elegance of blind debossing or the high-contrast impact of Spot UV, our team can guide you through the material selection and file preparation process.

Contact us today to request a quote or get a sample pack of our premium cover finishes.