Merging Tactile Engagement with Precision Manufacturing

Touch-and-feel books are a staple in early childhood development, bridging the gap between a toy and a reading experience. For publishers and brand owners, however, producing these books requires far more than standard offset printing. It involves a complex assembly process known as "handwork" or manual assembly, where distinct materials—faux fur, felt, silicone, corrugated paper, or mirrors—are physically integrated into the board book structure.

Unlike standard picture books, touch-and-feel production is a multi-disciplinary manufacturing challenge. It demands strict adherence to die-cutting tolerances, specialized adhesive selection, and rigorous safety testing to ensure that added parts do not become choking hazards. This guide outlines the technical steps, material considerations, and quality control measures necessary to manufacture high-quality sensory books for the international market.

The Anatomy of a Touch-and-Feel Book

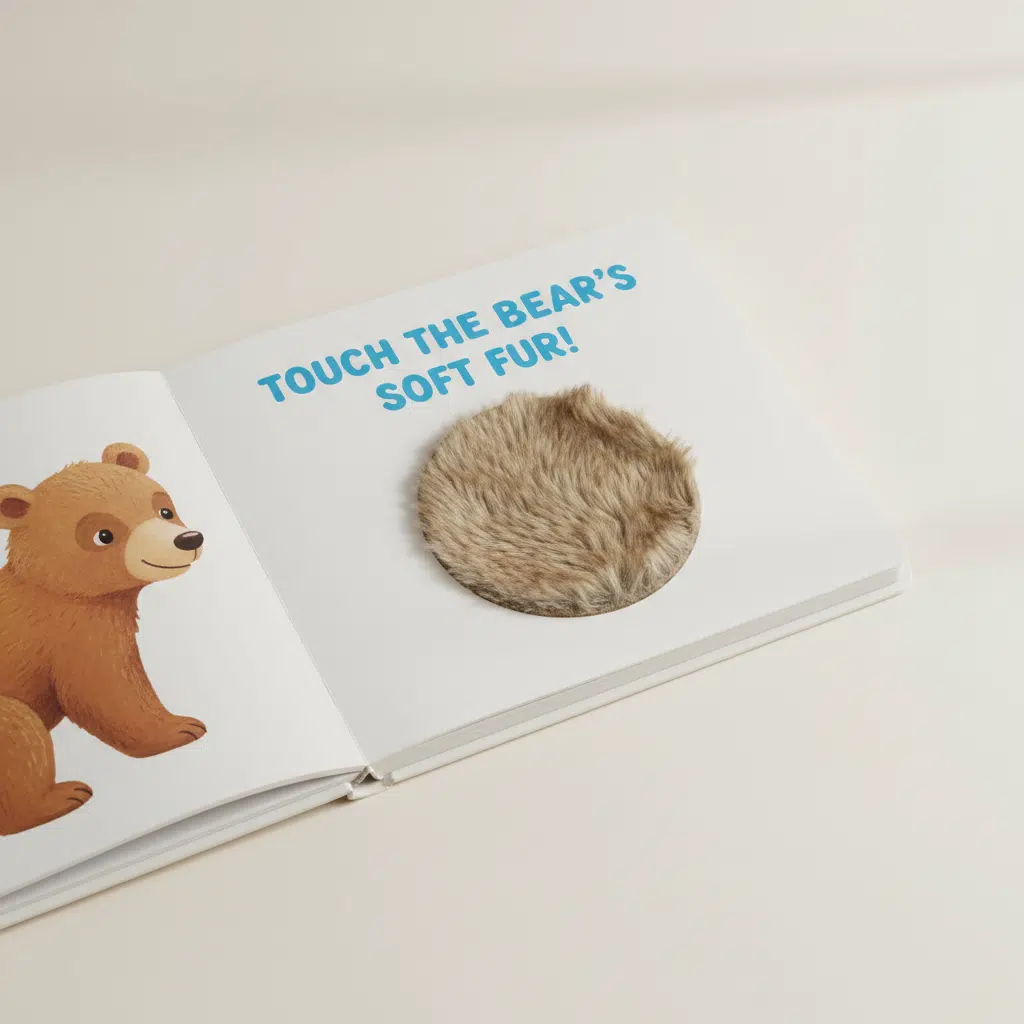

To understand the manufacturing complexity, one must first look at the construction. A standard board book consists of two sheets of C1S (Coated One Side) art paper mounted onto a greyboard core (or two C1S sheets mounted together for lighter weights). A touch-and-feel book modifies this structure significantly:

- Top Sheet (Die-Cut Layer): The visible page features a precise die-cut "window" where the texture will appear.

- Texture Insert: The fabric or material swatch is positioned behind the window. It is usually slightly larger than the opening (bleed) to ensure clean edges.

- Base Sheet (Mounting Layer): A backing sheet or the next board layer seals the texture in place, hiding the raw edges of the fabric and the glue points.

This "sandwich" construction increases the book’s spine thickness and requires careful calculation of the total bulk to ensure the cover binds correctly.

Material Selection: Balancing Aesthetics and Safety

The choice of materials dictates both the manufacturing cost and the safety profile of the final product. Common sensory elements include:

- Fabrics: Short-pile plush, long-pile faux fur, wool felt, and satin. These must be shed-resistant to prevent ingestion.

- Foils and Films: Holographic foils or "crinkle" materials (often Mylar) placed inside pages to create sound.

- Specialty Surfaces: Corrugated cardboard, EVA foam, sandpaper (simulated rough texture), or silicone patches.

- Mirrors: Safe, shatterproof plastic mirrors (usually acrylic or PET) are commonly used. These require protective film removal during or after assembly.

Note on Sourcing: Manufacturers typically source these accessories from specialized textile suppliers. It is critical that all raw materials—not just the paper and ink—pass chemical safety tests (such as EN71-3 or CPSIA) before mass production begins.

The Manufacturing Process Step-by-Step

1. Printing and Surface Finishing

Production begins with high-quality offset printing. Because touch-and-feel books are handled aggressively by toddlers, a protective coating is mandatory. Lamination (gloss or matte) is the industry standard as it prevents the paper from cracking during the die-cutting and mounting phases. UV varnishes are generally avoided for the main surface as they can crack at the spine, though spot UV is often used for visual contrast.

2. Precision Die-Cutting

This is the most critical mechanical step. The die-cutting tool creates the windows through which the textures will be felt.

- Tolerance: The die-cut position must align perfectly with the artwork. A shift of even 1-2mm can ruin the visual effect.

- Clean Edges: Dull blades can cause frayed paper edges around the window. Regular tooling maintenance is essential to ensure crisp cuts.

- Waste Removal: The "chad" or cutout piece must be fully removed (stripped) before assembly to prevent it from getting stuck in the final book.

3. Manual Assembly and Gluing

Unlike standard binding, inserting textures is primarily a manual or semi-automated process. This labor-intensive stage influences the lead time and cost.

- Adhesive Application: Workers apply glue to the back of the die-cut sheet. The glue must be strong enough to permanently secure the fabric but formulated to avoid "bleeding" through the fabric or soaking into the paperboard.

- Placement: The texture swatch is placed by hand over the glue area. Precision is key; if the fabric is misaligned, the underlying white board might show through the window.

- Drying Time: Sufficient curing time is required before the pages are mounted together to prevent warping or mold development, particularly if water-based glues are used.

4. Mounting and Binding

Once the textures are secured, the pages are collated and mounted (glued back-to-back). The book block is then trimmed to the final size. For board books, round cornering is a mandatory safety step to eliminate sharp points.

Safety and Quality Control Considerations

For children’s products targeting ages 0-3, safety is non-negotiable. Manufacturing defects in this category can lead to product recalls.

Pull Testing (Tension Test)

The most common failure point in touch-and-feel books is the detachment of the textured element. Manufacturers should conduct internal pull tests where a specific force (e.g., 90N) is applied to the texture to ensure it does not detach. If a child can pull a piece of plastic or button off, it becomes a choking hazard.

Chemical Compliance

All components must meet international standards. This includes:

- Heavy Metals: Inks and papers must be free of lead and heavy metals (EN71-3).

- Phthalates: Plastic elements and glues must be phthalate-free.

- Piezas pequeñas: Any added embellishment must be large enough not to fit in a small parts cylinder, or securely permanently attached so it cannot be removed.

Buying Guide: Preparing for Production

Prototypes and White Dummies

Before committing to mass production, request a "white dummy" with the actual materials inserted. This allows you to verify the thickness of the book and the tactile feel of the fabrics. Standard digital proofs cannot convey the physical bulk of a touch-and-feel book.

Die-Lines and Artwork

When preparing files, designers must include a separate layer for the die-cut lines. Ensure that the texture artwork (if printed behind the texture) extends well beyond the window (bleed) to account for slight manufacturing shifts.

Cantidades mínimas de pedido (CMP)

Due to the manual labor and material sourcing involved, MOQs for touch-and-feel books are often higher than standard booklets. Sourcing 10 different types of custom fabrics for a run of 500 books is often cost-prohibitive. Discuss material consolidation with your printer to optimize costs.

Preguntas frecuentes

Can I use my own fabrics?

While possible, it is logistically difficult. It is usually more efficient to specify the desired texture (e.g., "white short-pile fur") and allow the manufacturer to source compliant materials from their verified supply chain.

How does the texture affect the book’s spine?

Textures add bulk. If every page has a thick element, the spine will be significantly wider than the fore-edge, causing the book to fan open (wedge shape). Manufacturers compensate for this by adding spacers at the spine or staggering the position of textures across pages.

What is the typical lead time?

Touch-and-feel books generally require 1-2 weeks longer than standard board books due to the manual assembly and material procurement phases.

Are these books suitable for all ages?

They are primarily designed for infants and toddlers (0-3 years). Therefore, they must meet the strictest safety standards for this demographic.

Ready to produce high-quality interactive children’s books? Contact us today to discuss your specifications, request material samples, or get a custom quote.