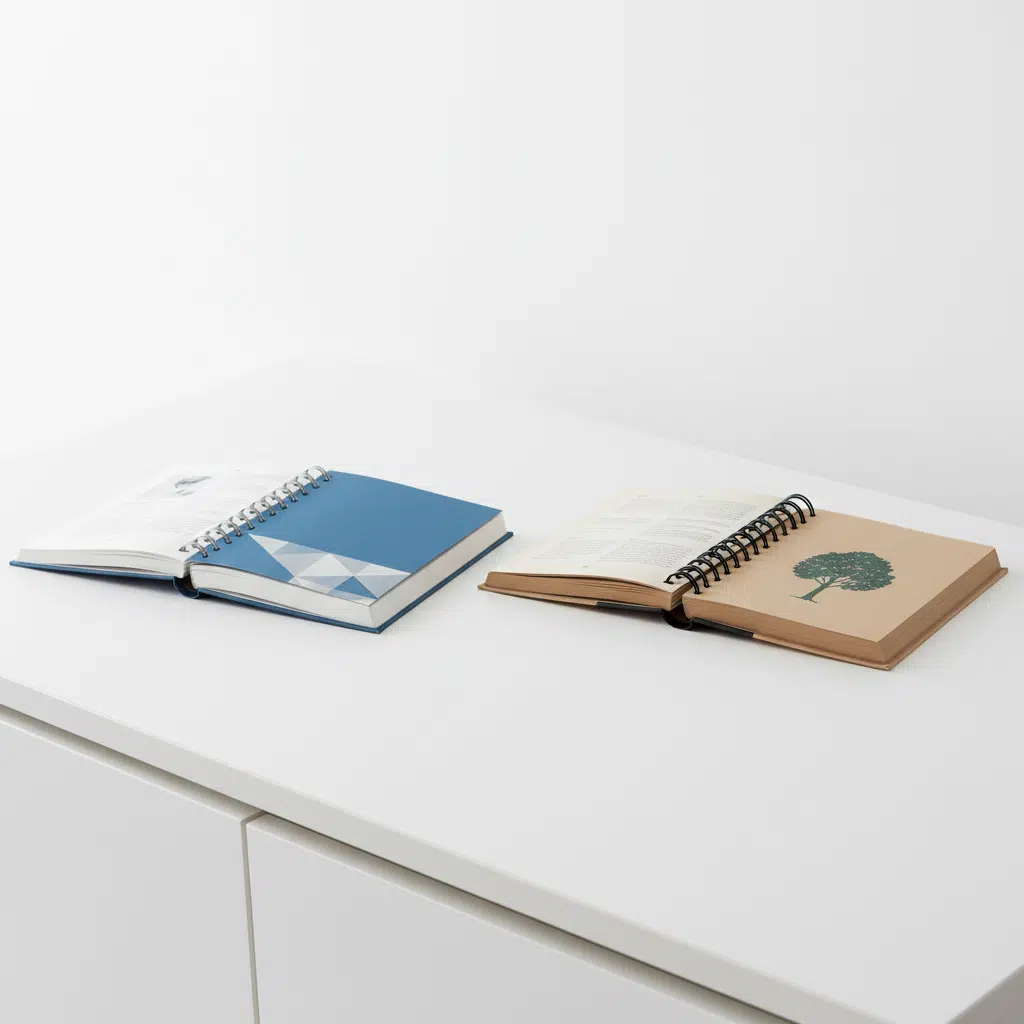

For functional publications like technical manuals, cookbooks, workbooks, and corporate planners, the binding method is not just an aesthetic choice—it is a functional necessity. These documents are tools; they must remain open hands-free, withstand frequent handling, and allow for easy navigation.

Two of the most popular mechanical binding solutions for B2B printing projects are Wire-O binding (also known as Twin-Loop or Double-Loop wire) and Reliure spirale (Plastic Coil). While they share the ability to open 360 degrees and lay completely flat, their durability, cost profiles, and visual presentations differ significantly.

This guide compares Wire-O and Spiral binding to help procurement managers and print buyers select the right specification for their project.

Defining the Contenders: Wire-O vs. Spiral

What is Wire-O Binding?

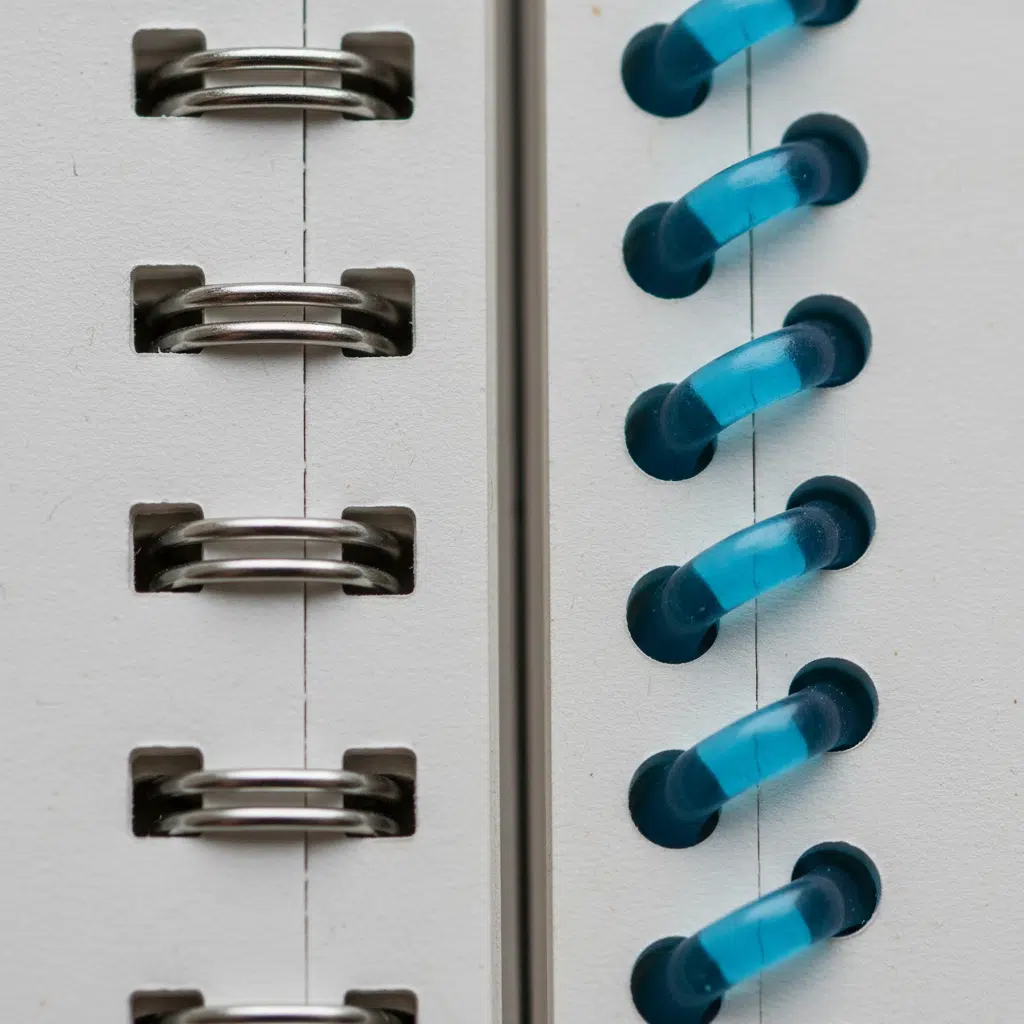

Wire-O binding uses a pre-formed metal wire that forms a “C” shape. The wire is inserted into square or round holes punched along the edge of the book block and then mechanically squeezed closed to form a round double-loop. It is widely regarded as the professional standard for corporate reports, high-end calendars, and presentation documents.

What is Spiral (Coil) Binding?

Spiral binding involves a continuous piece of plastic (PVC) filament formed into a helix (coil). This coil is spun through a series of closely spaced round holes along the binding edge. The ends of the coil are crimped to prevent it from spinning back out. It is commonly used for educational materials, restaurant menus, and industrial manuals due to its resilience.

Comparison at a Glance

| Fonctionnalité | Wire-O Binding | Spiral (Coil) Binding |

|---|---|---|

| Primary Material | Coated Metal Wire | Flexible PVC Plastic |

| Durabilité | Moderate (wire can bend/crush) | High (bounces back, crush-proof) |

| Aesthetics | Professional, Sleek, Corporate | Functional, Casual, Colorful |

| Page Alignment | Perfect registration (good for crossovers) | Slight step-up (offset) on open pages |

| Max Page Count | Typically up to 1.25″ thick | Can accommodate thicker books (up to 2″+) |

| Cost | Slightly higher premium | Generally more economical |

Deep Dive: Durability and Longevity

When selecting a binding method, consider the environment where the book will be used.

Spiral Binding: The Industrial Workhorse

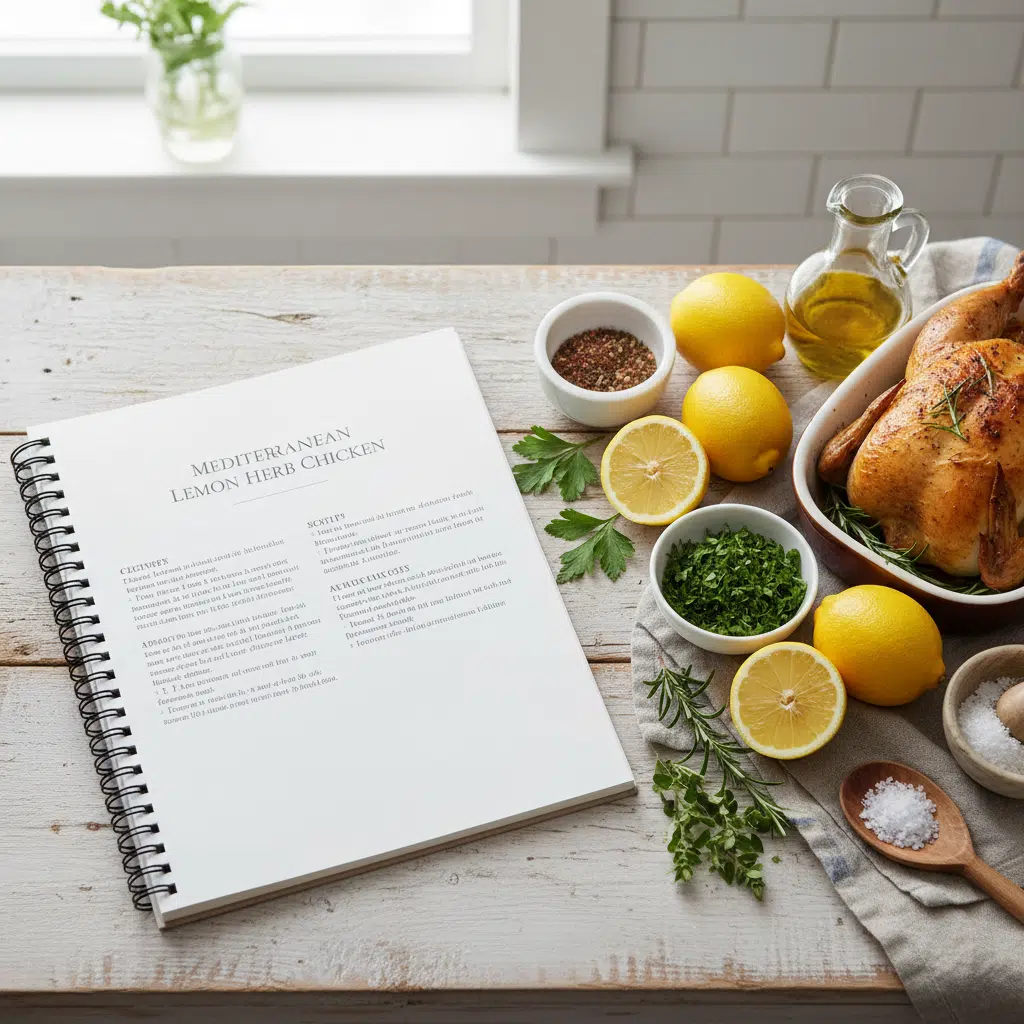

Plastic spiral binding is virtually indestructible in normal use. If a spiral-bound manual is dropped, stepped on, or shoved into a tight shipping box, the plastic coil flexes and springs back to its original shape. This makes it the superior choice for:

- Industrial safety manuals used on factory floors.

- School workbooks handled daily by students.

- Restaurant menus that face constant opening and closing.

Wire-O: Handle with Care

While Wire-O is sturdy, the metal loops can be crushed if heavy pressure is applied directly to the spine. Once the wire is bent out of shape, pages may become difficult to turn. Therefore, Wire-O is better suited for office environments, boardrooms, or products sold in protective packaging (like slipcases or shrink-wrap).

Aesthetics and Branding Considerations

Wire-O is generally preferred for projects where brand perception is paramount. The double-wire look is cleaner and more sophisticated. It is the standard for annual reports, architectural proposals, and high-end planners. Colors are typically restricted to black, white, silver, or pewter, keeping the look neutral and professional.

Reliure spirale offers more versatility in color matching but looks more utilitarian. The continuous coil can be manufactured in dozens of PMS colors to match a company logo or book cover design. However, the plastic finish can sometimes be perceived as less “premium” than metal.

Functionality: Crossovers and Registration

One technical detail often overlooked is crossover alignment—images or text that span across two facing pages (the spread).

- Wire-O: Keeps pages perfectly aligned horizontally. If you have a map or diagram spreading across the left and right pages, Wire-O ensures the lines meet accurately.

- Spiral: Because the coil travels in a helix, the left page is always slightly higher or lower than the right page when the book is open. This creates a “step” effect. Designers should avoid critical crossovers in spiral-bound documents to prevent misalignment.

Spécifications techniques pour les acheteurs

When requesting a quote for mechanical binding, specificity helps avoid delays.

Pitch and Hole Patterns

The “pitch” refers to the number of holes per inch.

- Wire-O Pitch: Typically 3:1 (3 holes per inch) for thinner books and 2:1 (2 holes per inch) for books thicker than 5/8 inch. Using the wrong pitch for the book thickness can result in difficult page turning.

- Spiral Pitch: Standard is usually 4:1 (4 holes per inch). The tighter hole spacing provides excellent tear resistance for the paper.

Cover Options

Both binding styles support various cover configurations:

- Soft Cover: Standard cardstock covers (C1S or C2S).

- Hard Cover (Exposed): A rigid board cover where the binding goes through the board itself.

- Semi-Concealed: The binding is visible on the inside back cover but hidden on the spine, offering a printable spine for shelf visibility (more common with Wire-O).

Manufacturing and Quality Control

At YBJ Printing, we emphasize strict quality control for mechanical binding to prevent common defects.

- Wire Closure: For Wire-O, the “C” wire must be closed into a perfect circle. If under-closed, pages fall out; if over-closed, pages won’t turn. We use automated binding lines to ensure consistent closure pressure.

- Coil Crimping: For spiral binding, the ends must be cut and crimped at a precise angle. Improper crimping leaves sharp plastic tails that can scratch users or snag on clothing.

Buying Guide: Lead Times and MOQ

When planning your order, consider the following:

- MOQ (Minimum Order Quantity) : While digital printing allows for lower volumes, industrial binding setups are most cost-effective at volumes of 500+ units.

- Colors: Standard black/white wire or coil is always in stock. Custom PMS colors for plastic coils may require longer lead times and higher minimums.

- Expédition : Wire-O books often require interleaving or careful packing to prevent the wire loops from scratching adjacent books or interlocking during transit.

Questions fréquemment posées

Which binding is cheaper?

Spiral binding is generally less expensive than Wire-O due to lower material costs and faster production speeds, though the difference narrows on short runs.

Can I print on the spine?

Neither standard Wire-O nor Spiral binding allows for a printable spine. If spine text is required for shelf display, ask about “semi-concealed” Wire-O or consider perfect binding instead.

What is the maximum thickness?

Spiral coils can bind books up to 2 inches (50mm) thick or more. Wire-O is typically limited to about 1.25 inches (32mm); beyond that, the wire becomes unstable and prone to opening.

Are these bindings eco-friendly?

Metal Wire-O is often coated with nylon but the core is steel, which can be recycled if separated. Plastic coils are typically PVC. For strict eco-requirements, ask about PET filament options or biodegradable alternatives.

Whether you need the durability of a spiral coil for a busy kitchen cookbook or the sleek precision of Wire-O for a corporate training manual, choosing the right binding ensures your product succeeds in the field.

Ready to start your project? Contact our team today to discuss your specifications and receive a custom quote.