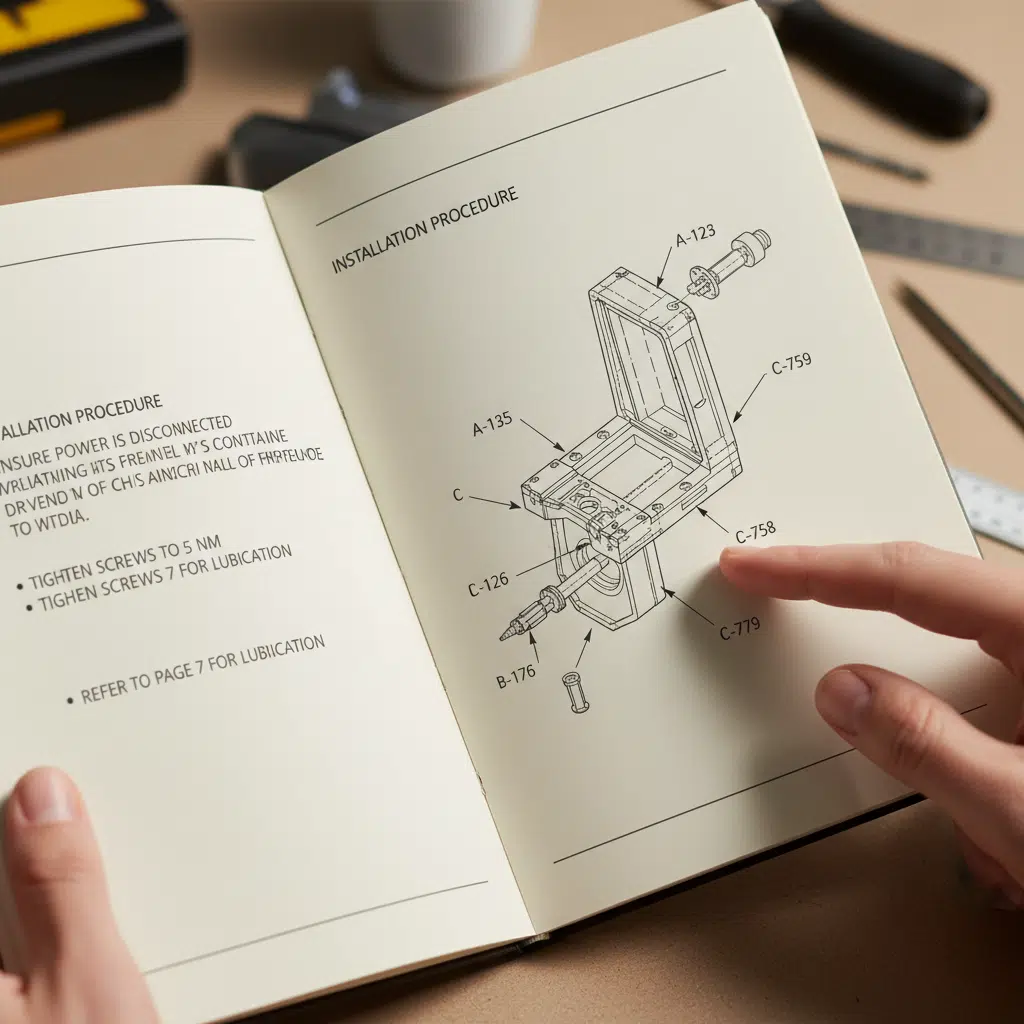

More Than Just Paper: The Role of Documentation in Manufacturing

For Original Equipment Manufacturers (OEMs) and product brands, the printed materials inside the box are as critical as the product itself. Whether it is a comprehensive instruction manual, a quick-start guide, or a warranty card, these packaging inserts serve two primary functions: compliance and customer experience.

A poorly printed manual with smudged ink or confusing folds reflects poorly on the brand. Conversely, a crisp, professional booklet enhances perceived value and ensures users can operate equipment safely. This guide covers the technical specifications, material choices, and strategic considerations for manufacturers sourcing custom instruction manual printing and packaging inserts.

Types of Packaging Inserts and Manuals

Choosing the right format depends on the volume of information, the size of the product packaging, and the budget. Here are the standard formats used in industrial and consumer packaging.

1. Saddle-Stitched Booklets

This is the most common format for instruction manuals ranging from 8 to 64 pages. Sheets are folded and stapled through the fold line. It is cost-effective and lies relatively flat, making it ideal for consumer electronics, kitchen appliances, and power tools.

2. Folded Leaflets (Mini-Fold/Map Fold)

When packaging space is tight—such as in cosmetics, pharmaceuticals, or small electronics—a large sheet folded down to a compact size is the standard solution. Complex folding techniques (like cross-folding or accordion folding) allow manufacturers to include extensive regulatory text and multilingual instructions without adding bulk.

3. Perfect Bound Manuals

For automotive guides, complex machinery documentation, or extensive software manuals (often exceeding 60-80 pages), perfect binding provides a square spine and a professional look similar to a paperback book. This method is durable and suitable for high-page-count documents.

4. Wire-O or Spiral Binding

For technical manuals that must lie completely flat on a workbench during use (e.g., maintenance logs or assembly guides), wire binding is the superior choice. It prevents the book from closing automatically, allowing hands-free reading.

5. Single Sheet Inserts & Cards

Warranty cards, “Thank You” notes, and Quick Start Guides often use heavier cardstock. These stand out from the standard paper manual and are often the first thing a customer sees.

Material Specifications: Paper Weight and Finish

Selecting the right paper stock impacts readability, durability, and cost. In B2B printing, we typically categorize paper by weight (GSM – grams per square meter) and finish.

Common Paper Weights

- 60gsm – 80gsm (Uncoated Woodfree): The standard for black-and-white text manuals. It is lightweight, cost-effective for high-volume runs, and easy to read without glare.

- 105gsm – 128gsm (Coated Art Paper): Often used for higher-end consumer products where color diagrams or photos are included. It feels smoother and more premium.

- 200gsm – 300gsm (Cardstock): Used for covers of thicker manuals or for standalone warranty cards and packaging inserts.

Coated vs. Uncoated

- Uncoated: Best for text-heavy technical documents. It absorbs ink well and has no glare, making it easier to read under bright factory or office lights.

- Matte/Gloss Coated: Gloss enhances colors in photographs but can cause glare. Matte coating offers a sophisticated, non-glare finish that protects the ink from smudging.

Strategic Considerations for OEMs

Multilingual Layouts vs. Regional Versions

Manufacturers exporting globally face a choice: print separate manuals for each region or combine all languages into one “global” manual.

Combined Manuals: Increases page count and weight but simplifies inventory management (one SKU for all markets).

Regional Manuals: Reduces printing costs per unit (fewer pages) but complicates logistics and inventory tracking.

Compliance and Safety Markings

Packaging inserts are often legal requirements. Ensure your artwork files include up-to-date compliance logos (CE, FCC, RoHS, UKCA) and safety warnings. Professional printers will check for print clarity on these critical small icons, but the accuracy of the content remains the responsibility of the manufacturer.

Kitting and Assembly

Consider how the manual fits into the final box. If your assembly line uses automated insertion, the manual must lie perfectly flat. If manual insertion is used, the paper must be durable enough to withstand handling without creasing.

Buying Guide: Ordering Custom Manuals

1. Minimum Order Quantity (MOQ)

Offset printing offers the lowest unit price but typically requires MOQs of 500 to 1,000 units to absorb setup costs. Digital printing is available for smaller batches or prototyping but comes at a higher unit cost.

2. Artwork Preparation

To ensure production quality, submit files as high-resolution PDFs (300 DPI) with bleed (usually 3mm). For black text, ensure it is set to 100% K (Black) rather than a rich black (CMYK mix) to ensure crisp, sharp text, especially for small font sizes.

3. Turnaround Time

Production times vary based on complexity. Standard saddle-stitched booklets can often be produced in 5-7 days after proof approval, while complex folded leaflets or perfect bound books may take longer. Always factor in shipping time for international orders.

FAQ: Printing Manuals & Inserts

What is the most cost-effective paper for instruction manuals?

For standard black-and-white manuals, 70gsm or 80gsm uncoated offset paper is the industry standard. It balances cost, opacity, and readability perfectly.

Can you print manuals on recycled paper?

Yes, many manufacturers now opt for recycled paper or FSC-certified paper to align with corporate sustainability goals. Soy-based inks are also an option for eco-friendly printing.

How do I choose between saddle stitching and perfect binding?

Use saddle stitching (staples) for documents under 64 pages. Use perfect binding (glued spine) for documents over 60-80 pages to ensure the book holds together and looks professional.

Do you handle kitting or packaging assembly?

Many printing partners offer fulfillment services, but this depends on the specific project scope. It is best to discuss kitting requirements during the quotation phase.

What information is needed for a quote?

To get an accurate quote, provide: final size (e.g., A4, A5), page count, quantity, paper preference (weight/type), binding style, and whether the artwork is ready.

Request a Quote for Your Printing Needs

Reliable documentation is a sign of a reliable product. Ensure your packaging inserts and instruction manuals match the quality of your manufacturing.

Contact us today to discuss your project specifications, request a sample pack, or get a competitive quote for your next production run.