Pour les responsables des achats, les propriétaires de marques et les équipes de production, le choix entre l'impression offset et l'impression numérique est rarement une simple question de préférence - c'est un calcul d'économie unitaire, d'exigences en matière de délais et de spécifications de qualité. Si l'impression numérique a comblé son retard en termes de qualité au cours de la dernière décennie, l'impression offset reste la norme industrielle pour les gros tirages commerciaux.

Making the wrong choice can lead to inflated budgets on long runs or missed deadlines on short ones. This guide provides a technical comparison of offset printing vs digital printing, offering a decision framework to help you optimize your supply chain for books, packaging, and marketing collateral.

The Fundamental Difference: Mechanics and Process

To understand the cost structure, one must first understand the mechanics. The primary distinction lies in how the image is transferred onto the substrate (paper or board).

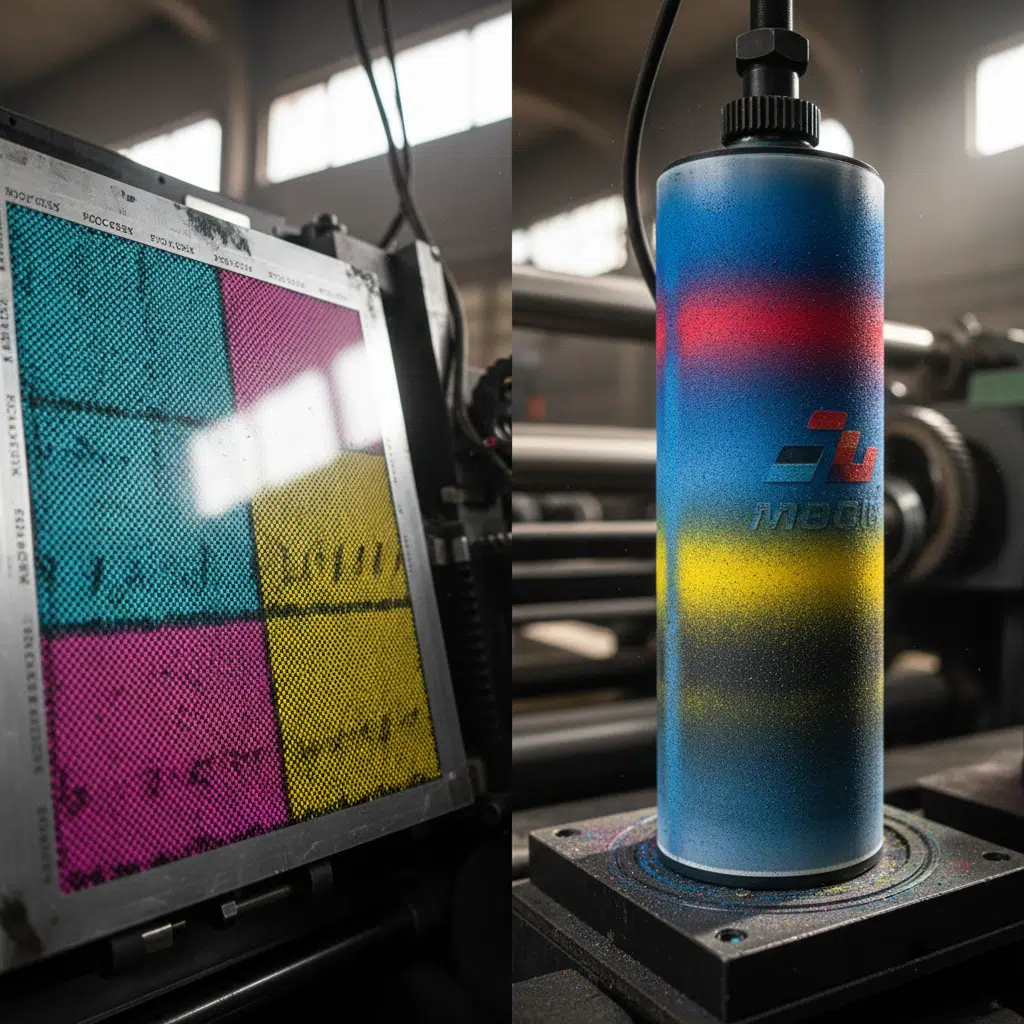

Offset Printing (Lithography)

Offset printing is an analog process. It uses etched metal plates (one for each color: Cyan, Magenta, Yellow, and Key/Black) to transfer ink onto a rubber blanket, which then rolls the image onto the paper. This process requires significant setup time, known as “make-ready,” which includes imaging plates and calibrating the press for color registration.

Because of this setup, Qu'est-ce que l'impression offset ? La norme pour les tirages commerciaux de haute qualité is typically the most cost-effective method for large quantities. Once the press is running, the variable cost per sheet is negligible compared to digital methods.

Impression numérique

Digital printing eliminates plates entirely. It uses electrostatic rollers (toner) or inkjet heads to apply color directly to the paper from a digital file. This allows for “print-on-demand” agility. There is almost no setup time, meaning the first sheet costs roughly the same as the thousandth sheet.

For a broader overview of how these methods fit into the wider publishing landscape, see our Un guide complet des méthodes d'impression de livres : Offset, numérique et POD.

Cost Analysis: The “Crossover Point”

In B2B printing procurement, the most critical concept is the “crossover point.” This is the specific quantity where offset printing becomes cheaper per unit than digital printing.

- Low Volume (Under 500 units): Digital is generally more economical. You avoid the fixed costs of plate production and press setup.

- Mid-Range (500 – 1,000 units): This is the typical crossover zone. The decision here often depends on the specific dimensions, page count, and finishing requirements.

- High Volume (1,000+ units): Offset becomes significantly cheaper. As volume increases to 5,000, 10,000, or 50,000 units, the unit price drops dramatically because the fixed setup costs are amortized over a larger number of copies.

If you are sourcing from overseas, specifically when you Pourquoi choisir une imprimerie chinoise pour les commandes en gros ? Avantages stratégiques pour les acheteurs mondiaux, the economies of scale with offset printing are even more pronounced. Large-scale factories are optimized for long runs, utilizing large-format offset presses that can print 16 or 32 pages on a single sheet, drastically reducing press time and cost.

Quality and Substrate Versatility

While cost is a primary driver, technical specifications often dictate the method.

Color Accuracy (Pantone vs. CMYK)

Offset printing is the superior choice for brand fidelity. It allows for the use of pre-mixed Pantone (PMS) inks. If your corporate branding requires a specific spot color (e.g., Coca-Cola Red or Tiffany Blue), offset ensures a 100% match. Digital printing simulates these colors using CMYK toner, which can get close but rarely achieves a perfect match for bright or metallic hues.

Paper and Material Options

Offset presses can handle a vast array of substrates, from lightweight bible paper to heavy rigid boxboard, as well as textured, rough, or synthetic stocks. Digital presses have tighter restrictions on paper weight and texture. For specialized products like board books, the heavy cardstock and durability requirements almost exclusively demand offset production. Learn more about the nuances of Découvrir l'art et l'artisanat de l'impression de livres cartonnés : Un guide complet.

Decision Framework: When to Choose Which

Use this table to guide your procurement strategy based on your project constraints.

| Factor | Choose Digital If… | Choose Offset If… |

|---|---|---|

| Quantité | 1 – 500 copies | 500 – 100,000+ copies |

| Retournement | Urgent (24–48 hours) | Standard (5–10 days + logistics) |

| Personalization | Variable Data (names/codes per sheet) | Static content (identical copies) |

| Color Precision | Standard CMYK is acceptable | Pantone (PMS) matching is critical |

| Matériau | Standard papers (80gsm – 300gsm) | Heavy board, textured, plastic, metallic |

| Taille | Standard A4/A3 formats | Large format (Posters, Packaging) |

Strategic Considerations for Bulk Orders

For international buyers managing bulk orders, the manufacturing process involves more than just hitting “print.” Here is how to navigate the workflow effectively.

1. Sampling and Proofing

A common hybrid strategy involves using digital printing for proofs and offset for the final run. However, be aware that a “digital proof” may look slightly different than the final “offset run” due to the different ink technologies. For critical color matching, request a “wet proof” (a short run on the actual offset press), though this incurs setup costs.

2. Timeline Management

Offset printing requires time for plate imaging, mounting, and drying (if not using UV inks). When planning your supply chain, factor in:

- File Prep: 1-2 days

- Proofing & Approval: 3-7 days (depending on shipping of physical proofs)

- Production: 7-15 days (depending on complexity and finishing)

3. Minimum Order Quantities (MOQ)

While a factory may accept an order of 300 units for offset, the unit price will be high. To maximize ROI, target an MOQ of at least 1,000 units. This volume justifies the machine setup and freight consolidation.

Questions fréquemment posées

Can I use Variable Data Printing (VDP) with offset?

No. Offset plates are static. If you need unique codes, names, or addresses on each piece, you must use digital printing or a hybrid method (printing the shell via offset and overprinting variable data digitally).

Is the print quality of digital comparable to offset?

For standard text and images, modern high-end digital presses (like HP Indigo) produce results indistinguishable to the untrained eye. However, for large solid blocks of color, gradients, and very fine text, offset generally produces a smoother, sharper result.

Does offset printing take longer to dry?

Traditional offset inks soak into the paper and oxidize, which takes time. However, modern offset presses often use UV curing, which dries ink instantly using ultraviolet light, speeding up the bindery process.

Conclusion

Choosing between offset and digital printing is a strategic balance of cost, volume, and quality requirements. Digital offers speed and agility for short runs and prototypes, while offset remains the undisputed king of high-volume, high-quality commercial manufacturing.

At YBJ Printing, we specialize in helping global clients navigate these decisions to ensure their packaging, books, and marketing materials are produced efficiently and to specification.

Ready to optimize your next print run? [CTA_TEXT] today to discuss your project specifications and receive a custom cost analysis.