Elevating Art Through Print Specification

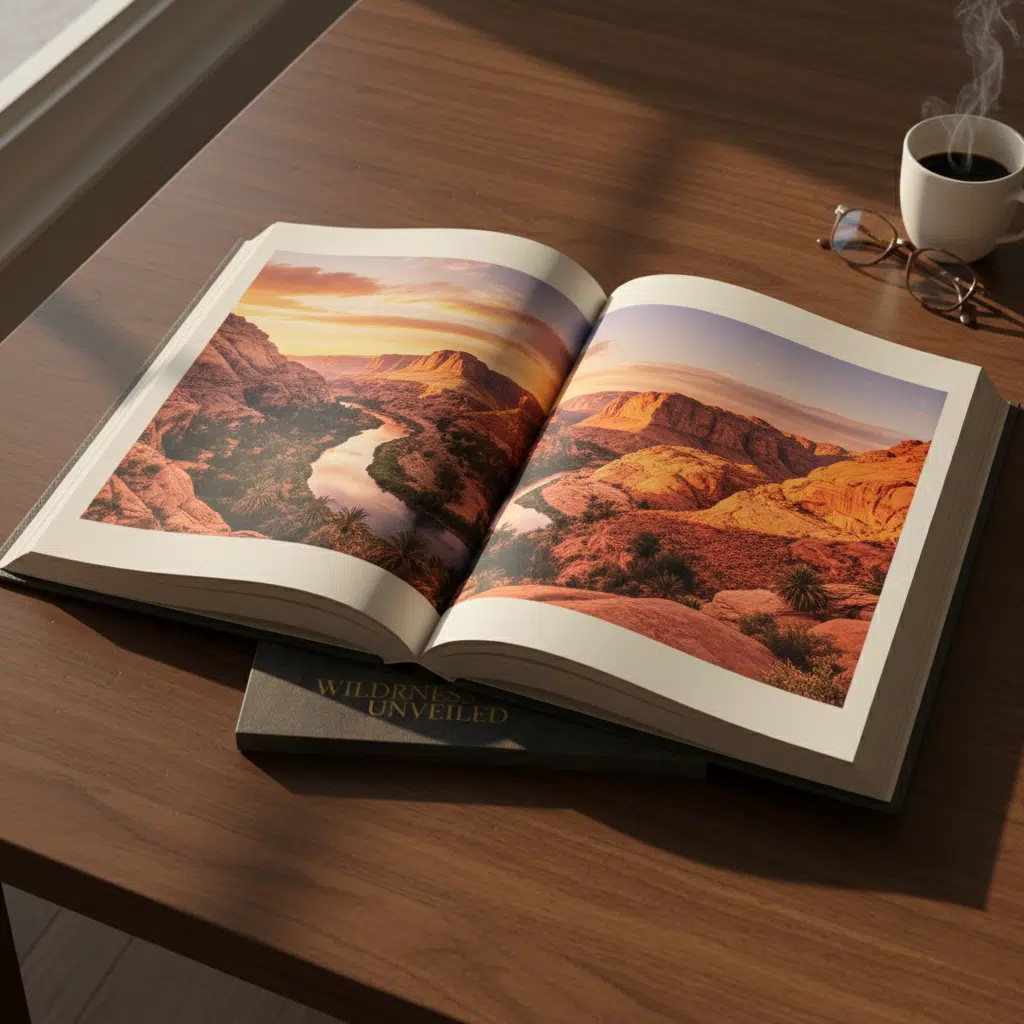

For photographers, artists, and gallery owners, a coffee table book is more than a portfolio—it is a physical extension of the artwork itself. The perceived value of these publications relies heavily on tactile qualities: the weight of the page as it turns, the way light interacts with the ink, and the durability of the binding.

In the world of B2B offset printing, achieving a "luxury" feel requires precise specification of paper density (GSM) and surface treatments. Standard commercial printing settings often fall short for visual-heavy projects. This guide outlines the technical choices required to produce gallery-quality coffee table books that stand the test of time.

Understanding Paper Weight (GSM) for Art Books

Paper weight is measured in Grams per Square Meter (GSM). In the context of luxury coffee table books, the goal is to prevent show-through (opacity) while ensuring the pages drape elegantly when the book is open.

Standard vs. Luxury Text Block Weights

- 128gsm – 157gsm: This is the industry standard for high-quality brochures and magazines. While cost-effective, 128gsm may feel too flimsy for a premium art book. 157gsm is a safe baseline for substantial feel without excessive bulk.

- 170gsm – 200gsm: This range represents the "sweet spot" for luxury photography books. The paper is thick enough to support heavy ink coverage without warping or bleeding through to the reverse side. It provides a stiffness that signals quality to the reader.

- Above 200gsm: While impressive, paper heavier than 200gsm can make a book difficult to browse if the binding method isn’t adjusted. It is best reserved for books with lower page counts (under 100 pages) to prevent the spine from becoming unwieldy.

Cover Board Thickness

For hardcover (case-bound) books, the internal greyboard determines the rigidity of the cover. A standard hardcover might use 2mm or 2.5mm board. For a truly substantial, luxury feel—especially for large-format books (e.g., 11×14 inches)—specifying a 3mm greyboard adds significant heft and durability.

Surface Finishes: Balancing Vibrancy and Readability

The interaction between ink and paper surface defines the final image quality. Choosing between gloss, matte, and uncoated stocks is a strategic decision based on the type of art being reproduced.

Gloss Art Paper

Meilleur pour : High-contrast photography, landscapes, and commercial product imagery.

Gloss coating keeps the ink on the surface of the paper rather than letting it absorb. This results in the sharpest details and most vibrant colors. However, the high reflectivity can cause glare under direct light, which may distract from the reading experience in text-heavy sections.

Matte Art Paper

Meilleur pour : Portraits, fine art, and black-and-white photography.

Matte paper offers a sophisticated, non-reflective surface that feels smooth to the touch. It is excellent for readability. The trade-off is that matte coatings can slightly flatten color contrast compared to gloss. To counter this, high-quality offset printing often employs "spot gloss varnish" on the images themselves to bring back the pop while keeping the surrounding paper matte.

Silk or Satin Finish

Meilleur pour : The versatile middle ground.

Silk (often called satin) is the most popular choice for modern luxury coffee table books. It offers excellent color reproduction similar to gloss but without the harsh glare. It provides a refined, premium texture that works well for both text and images.

Uncoated Woodfree Paper

Meilleur pour : Artistic illustrations, watercolors, and organic subjects.

Uncoated paper has a rougher, natural texture. It absorbs more ink, resulting in softer images and a slight loss of sharpness (dot gain). While not recommended for high-precision technical photography, it conveys an organic, artisanal aesthetic highly valued in specific niche markets.

Binding and Special Effects

The manufacturing process for luxury books involves more than just printing pages. The construction and finishing touches are critical.

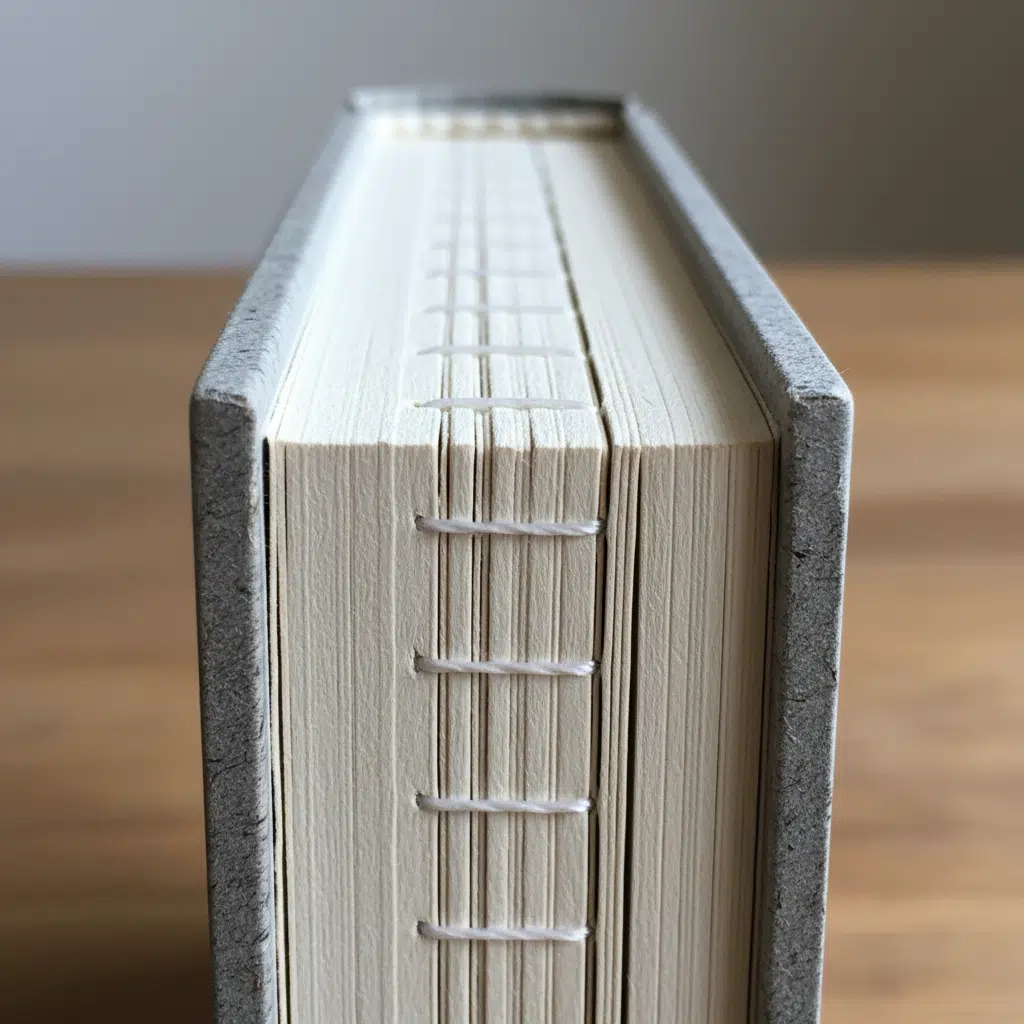

Smyth Sewn Binding (Section Sewn)

For any coffee table book, Smyth sewn binding is mandatory. Unlike perfect binding (glue only), sewn binding allows the book to lay completely flat when open. This is essential for panoramic photos that span across a two-page spread (crossover images), ensuring no detail is lost in the gutter.

Cover Treatments

To differentiate a book on the shelf, consider these post-press finishes:

- Marquage à la feuille : Applying metallic gold, silver, or colored foil to the title or logo.

- Debossing/Embossing: Creating a tactile depression or raised relief on the cover material (often linen or cloth).

- Spot UV : A high-gloss clear varnish applied only to specific areas (like a photo on a matte cover) to create contrast.

- Dust Jackets: A removable paper wrap that adds an extra layer of protection and marketing space.

Pre-Press and Quality Assurance

When manufacturing thousands of copies, consistency is key. Professional printers use specific protocols to ensure the final output matches the artist’s vision.

Color Management

Files must be prepared in CMYK color mode. RGB files (used for screens) have a wider color gamut than physical ink; converting them properly prevents unexpected color shifts. High-end printing houses will request high-resolution PDFs (300 DPI minimum).

Proofing Stages

- Digital Proof (Soft Proof): A PDF to check layout, text, and pagination. Not used for color accuracy.

- Hard Proof (Plotter/Ozalid): A low-resolution physical mock-up to check page order and binding structure.

- Wet Proof (Contract Proof): For luxury projects, requesting a wet proof for critical images is advisable. This involves printing a few pages on the actual production machine and paper. It is the most expensive option but the only way to guarantee exact color matching before the full run.

Buying Guide: Logistics and Timelines

Quantités minimales de commande (QMC)

Offset printing entails significant setup costs (plate making, machine calibration). Consequently, the typical MOQ for custom luxury books is 500 to 1,000 units. While lower quantities are possible via digital printing, the paper options and binding quality generally do not match offset standards for luxury tiers.

Délais de production

A typical timeline for a luxury coffee table book project includes:

- Examen des dossiers et épreuvage : 1-2 semaines

- Production de masse : 2–4 weeks (depending on complexity and finishing)

- Expédition : 4–6 weeks (for international sea freight)

Summary Checklist for Premium Books

| Component | Recommendation for Luxury |

|---|---|

| Inner Paper | 157gsm – 200gsm Matte or Silk Art Paper |

| Cover Board | 3mm Greyboard wrapped in printed paper or cloth |

| Reliure | Smyth Sewn (Lay-flat) Hardcover |

| Finishing | Spot UV, Foil Stamping, or Debossing |

Questions fréquemment posées

What is the difference between C1S and C2S paper?

C1S stands for "Coated One Side," typically used for postcards or packaging boxes where the back is unprinted. C2S ("Coated Two Sides") is the standard for book pages, ensuring both sides of the sheet have a uniform finish for double-sided printing.

Can I print a sample copy before ordering 500?

Yes, most printers can provide a digitally printed sample. However, be aware that digital samples may differ slightly in color and texture from the final offset production run. For critical color matching, ask about GMG color proofs.

How do I prepare files for foil stamping?

Foil stamping requires a separate vector layer in your design file (usually a spot color named "Foil"). This indicates exactly where the die should be created. Ensure these elements are set to "overprint" in your design software.

Selecting the right materials is the first step in transforming a collection of images into a masterpiece. If you are ready to discuss specifications for your next project, our team is here to guide you through the options.