The Challenge of Fidelity in Art Reproduction

For museums, galleries, and independent artists, an art book is not merely a collection of pages—it is an archival record of the work itself. The primary challenge in art book printing is bridging the gap between the luminous, backlit colors seen on a calibrated monitor and the physical reality of ink on paper. A slight shift in hue or saturation can alter the mood of a photograph or misrepresent a painting’s original palette.

Achieving museum-quality results requires a rigorous approach to color management. It demands a technical understanding of how light-based colors (RGB) translate to pigment-based printing (CMYK) and a manufacturing partner capable of executing high-precision offset printing. This guide outlines the essential steps to ensure what you see on the screen is what is delivered on the pallet.

The Fundamental Conflict: RGB vs. CMYK Gamuts

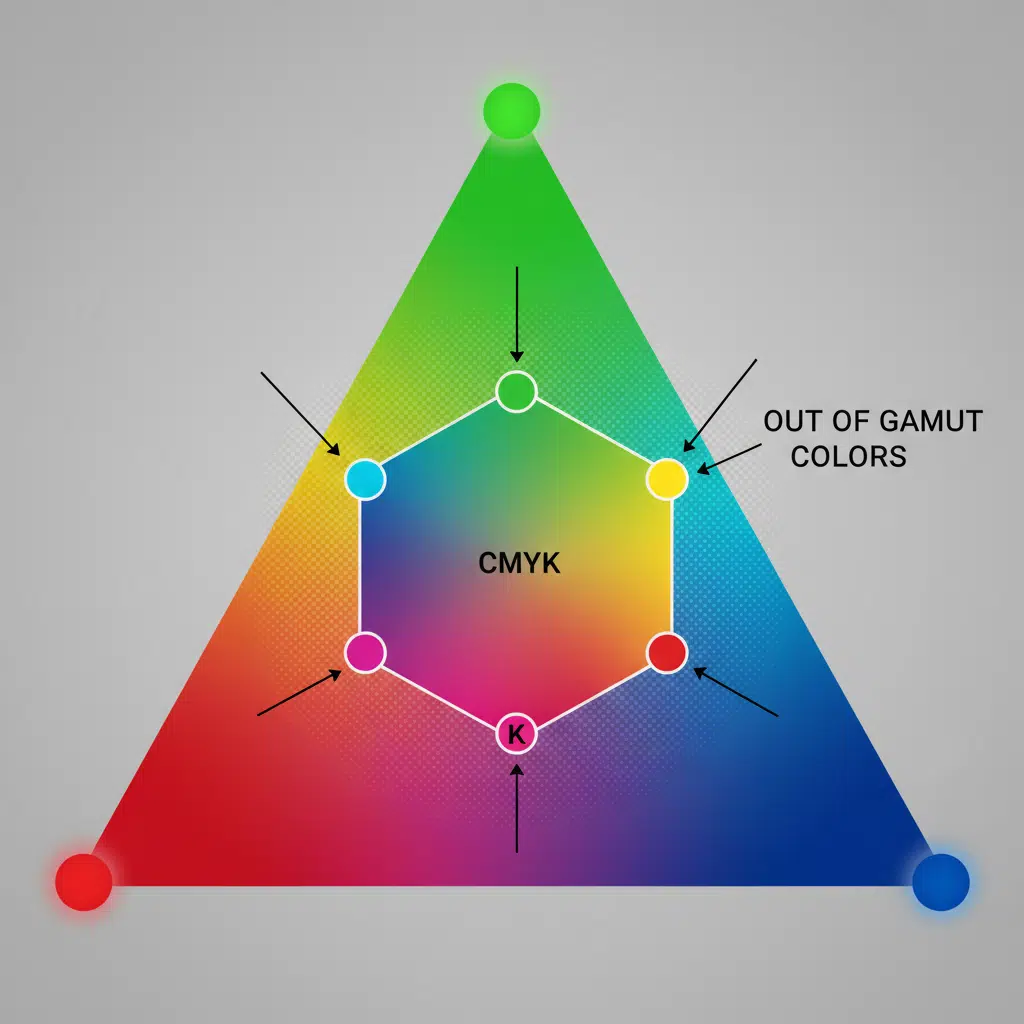

The root of most color discrepancies lies in the fundamental difference between color spaces. Digital cameras and monitors use RGB (Red, Green, Blue), an additive color model capable of displaying a vast spectrum of vibrant, neon-like colors. Offset printing uses CMYK (Cyan, Magenta, Yellow, Black), a subtractive model where inks are layered to absorb light.

The CMYK color gamut is physically smaller than the RGB gamut. Certain colors—particularly bright oranges, electric blues, and neon greens—exist outside the printable range of standard four-color process printing. When an RGB file is converted to CMYK without manual adjustment, the software automatically compresses these “out-of-gamut” colors to the nearest printable equivalent. This often results in muddy or flattened tones.

Managing the Conversion

- Convert Early: Do not leave the RGB-to-CMYK conversion to the automated ripping process at the factory. Designers should convert images in Photoshop using the specific ICC profile recommended by the printer (e.g., FOGRA39 or GRACoL).

- Soft Proofing: Use professional design software to simulate how the colors will look on paper. This allows you to manually adjust saturation and curves to preserve detail in shadow areas that might otherwise clog up during printing.

The Critical Role of Wet Proofs

In standard commercial printing, a digital proof (often called a “plotter” or Epson proof) is sufficient for checking layout and text. However, for art books where color fidelity is paramount, digital proofs are often inadequate. Digital printers use different toners or inkjet technologies that behave differently than offset ink.

Wet proofs (or hard proofs) are the gold standard for high-end art book production. A wet proof involves setting up a proofing press to print a single copy of the signature using the actual offset plates, the actual ink, and the actual paper stock specified for the final run.

Why Wet Proofs are Necessary for Art Books

- Substrate Interaction: They reveal exactly how the ink interacts with the paper fibers. Uncoated papers, for example, suffer from “dot gain” (ink spreading), which darkens images. A wet proof shows this effect definitively.

- Finitions spéciales : If your project involves spot UV, varnish, or metallic inks, a wet proof is the only way to accurately gauge the final aesthetic.

- Contractual Color: A signed wet proof serves as the manufacturing standard. The press operator matches the production run to this approved sheet, ensuring consistency.

While wet proofs incur higher upfront costs and take longer to produce than digital proofs, they are the only insurance policy against disappointing results in a high-stakes museum catalog or photography book.

Paper Selection and Color Perception

The canvas determines the outcome. The whiteness, brightness, and texture of the paper significantly influence color perception.

- Coated Gloss/Matte: Ink sits on top of the coating, resulting in sharper details and more vibrant colors. This is the standard for photography books requiring high contrast.

- Uncoated / Fine Art Paper: Ink absorbs into the fibers. This creates a softer, more tactile feel often preferred for watercolors or historical archives. However, colors will appear more muted. To compensate, prepress technicians must apply specific curves to open up the shadows and increase saturation.

Always request blank paper dummies to assess the weight and feel, but rely on printed proofs to assess color performance.

Pre-Press Checklist for Art Book Production

To streamline production and minimize errors, ensure your files meet these technical specifications before submission:

| Element | Requirement | Why it Matters |

|---|---|---|

| Resolution | 300 DPI minimum at 100% scale | Prevents pixelation and blurriness in fine art details. |

| Color Mode | CMYK | Ensures you control the color shift, not the machine. |

| Blacks | Rich Black (e.g., C60 M40 Y40 K100) | Standard 100% K looks dark grey on large areas; Rich Black looks deep and neutral. |

| Bleed | 3mm minimum (standard) | Ensures images extending to the edge are not cut off with white borders. |

| Fonts | Outlined or Embedded | Prevents font substitution errors. |

Manufacturing Quality Control

Even with perfect files, the printing process itself requires strict controls. High-quality art book printers utilize closed-loop color control systems (such as Heidelberg’s Inpress Control) to monitor ink density in real-time. Additionally, standard lighting conditions (D50 usually) must be used when viewing proofs and press sheets to avoid metamerism, where colors look different under different light sources.

When selecting a printing partner, ask about their quality assurance (QA) protocols. Do they perform press checks? Are they experienced in handling heavy ink coverage without offsetting (ink transferring to the facing page)?

Summary: Investing in Quality

Producing a museum-quality art book is a collaboration between the artist’s vision and the printer’s technical capability. By understanding the limitations of CMYK, choosing the right paper, and investing in wet proofs for critical pages, you can ensure the final product honors the original artwork.

At YBJ Printing, we specialize in high-fidelity offset printing for the global art and publishing community. We understand that for your project, “close enough” is not enough.

Questions fréquemment posées

Q: Can you match a Pantone color using CMYK?

A: We can simulate most Pantone colors using CMYK, but some bright shades cannot be perfectly matched. For exact branding or art colors, we recommend adding a 5th Pantone spot color plate.

Q: Why do my images look darker on uncoated paper?

A: Uncoated paper absorbs more ink, causing “dot gain.” We adjust for this during the pre-press stage, but we always recommend seeing a proof on the actual stock.

Q: What is the minimum order quantity (MOQ) for art books?

A: Due to the setup costs of offset printing and wet proofing, the most cost-effective MOQ typically starts at 500 or 1,000 copies. Short-run digital options exist but may not match offset quality for art reproduction.

Ready to bring your art book to life with precision and care?

Request a Quote or Sample Kit Today