For educational institutions and yearbook publishing companies, the annual yearbook is more than just a printed product; it is a historical record meant to be referenced for decades. Unlike marketing brochures or catalogs that have a short lifecycle, a yearbook must withstand repeated handling, shelf storage, and environmental changes over 50 years or more.

Ensuring this longevity requires specific manufacturing choices. The durability of a yearbook is primarily determined by two factors: the mechanical strength of the binding and the chemical stability of the paper. For procurement managers and school administrators, understanding the technical differences between binding methods—specifically Smyth sewn versus standard perfect binding—is critical to producing a volume that stays intact.

This guide explores the industrial specifications required to create durable, archival-quality school yearbooks.

Why Durability Matters for School Yearbooks

Yearbooks face a unique usage profile. Upon delivery, they are opened flat, signed by students, and handled roughly. Over time, they sit on shelves where gravity pulls at the spine. If the binding relies solely on adhesive, the pages will eventually crack and fall out—a common failure point in budget-friendly printing options.

To prevent product failure, buyers must specify materials and assembly methods designed for high-stress applications. This often means moving beyond standard commercial print settings to request library-grade or archival specifications.

The Gold Standard: Smyth Sewn Binding

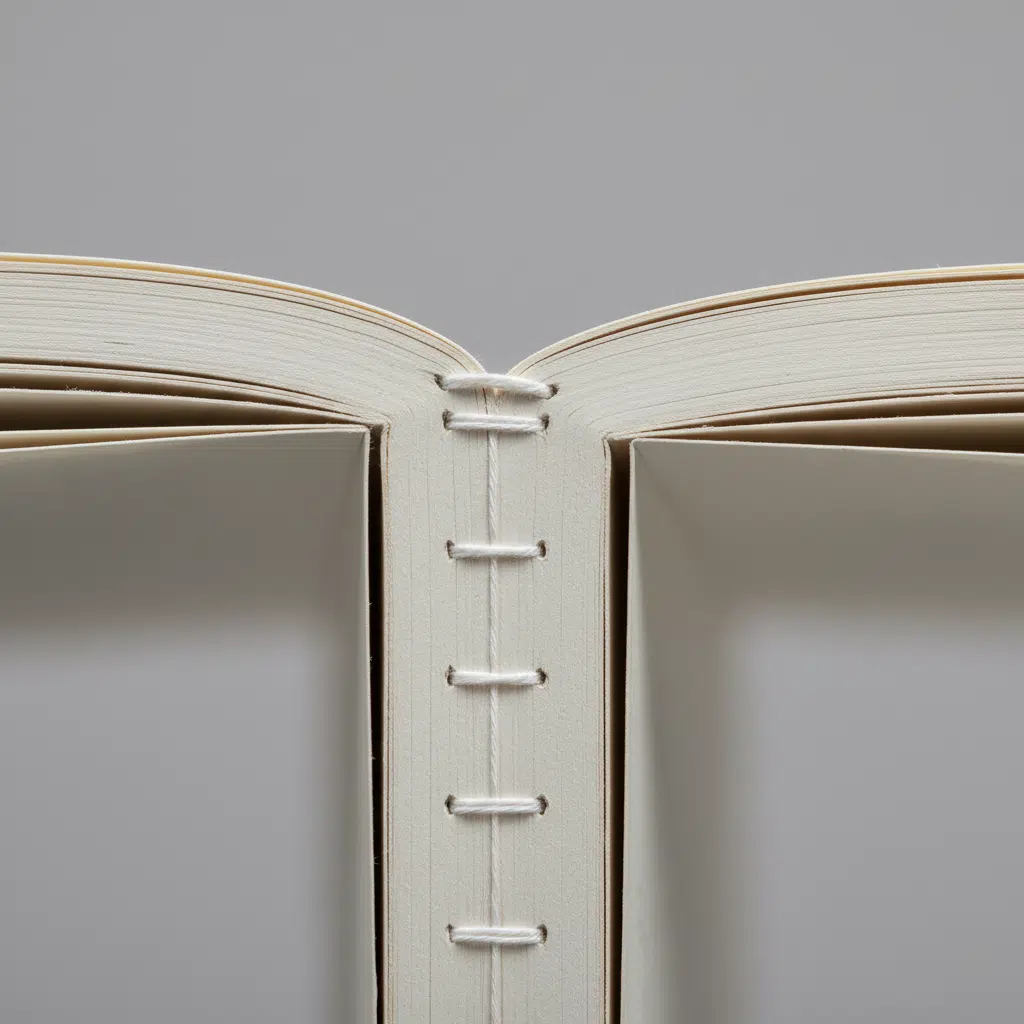

While there are several ways to bind a book, Smyth sewn binding (also known as section-sewn binding) is the undisputed industry standard for high-quality yearbooks. It offers the highest level of durability and lay-flat capability.

How Smyth Sewing Works

In the Smyth sewing process, printed sheets are folded into groups called signatures (typically 16 or 32 pages). These signatures are then stitched together through the fold using industrial-strength thread. Once sewn, the block of pages is reinforced with adhesive on the spine, but the structural integrity comes from the thread, not the glue.

This mechanical linkage ensures that pages cannot simply fall out if the glue dries or becomes brittle over decades. Furthermore, because the pages are sewn at the spine, the book can open almost completely flat without breaking the spine—crucial for double-page photos and signing sessions.

Smyth Sewn vs. Perfect Binding

Many commercial books use reliure parfaite (PUR or EVA glue), where pages are cut at the spine and glued directly to the cover. While cost-effective for paperbacks, standard perfect binding is risky for heavy yearbooks. The rigid layer of glue can crack when the book is forced open flat, leading to page detachment.

Recommendation: For any hardcover yearbook exceeding 40 pages, specify Smyth sewn binding. The marginal cost increase is justified by the significant reduction in failure rates.

Selecting Archival-Quality Paper

The paper substrate is the foundation of print longevity. Paper that yellows or becomes brittle over time does so because of high acid content (often from wood pulp lignin). For yearbooks, acid-free archival paper is a mandatory specification.

Understanding Acid-Free Paper

Acid-free paper has a neutral or basic pH (7.0 or higher). It is manufactured to resist deterioration and yellowing for over 100 years. When requesting quotes, confirm that the stock is wood-free or has been treated to neutralize acids.

Recommended Paper Weights and Finishes

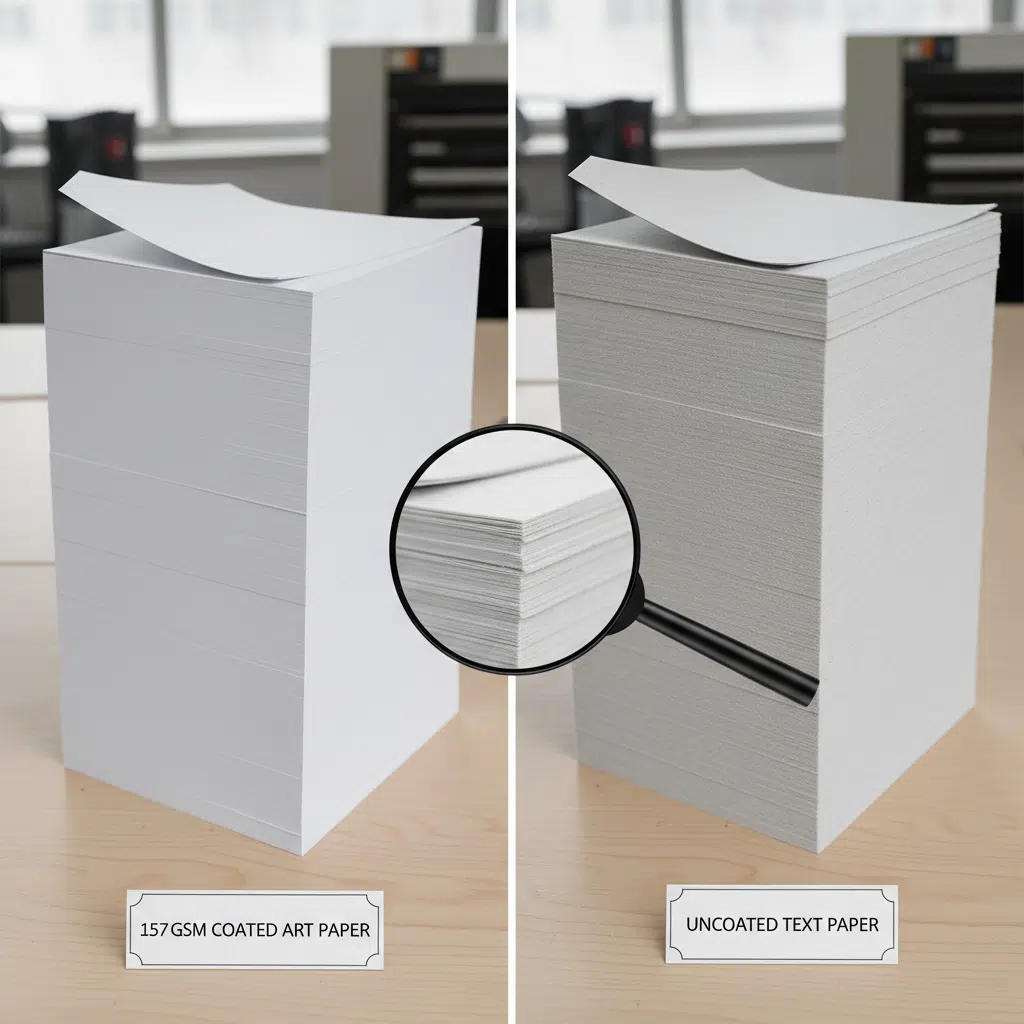

The tactile feel of a yearbook conveys quality. Using flimsy paper can make the book feel cheap and allow ink show-through (opacity issues).

- 128gsm (approx. 85lb Text): The standard baseline for yearbooks. Offers decent opacity and durability.

- 157gsm (approx. 105lb Text): A premium choice. Thick, substantial, and highly opaque. Ideal for heavy ink coverage and full-color photos.

- Gloss vs. Matte: Gloss coated paper makes photographs pop with vibrancy, which is popular for student photos. Matte or silk coated paper reduces glare and provides a more sophisticated, readable finish for text-heavy sections.

Hardcover Casemaking for Longevity

The outer shell, or “case,” protects the interior book block. A durable hardcover case is constructed by wrapping a printed cover sheet (or cloth/leatherette) around rigid greyboard.

Board Density and Thickness

Standard greyboard thickness for yearbooks is typically 2.5mm to 3mm. Thinner boards (2mm) may warp over time due to humidity changes. High-density board resists bending and corner crushing.

Cover Finishes and Protection

To protect the printed cover art from scratches and fingerprints, a lamination layer is essential:

- Anti-scratch Matte Lamination: Highly recommended for yearbooks. It resists the scuffs that occur when books are slid across tables or shelves.

- Spot UV and Foil Stamping: These add aesthetic value but should be applied over a durable lamination layer to ensure they don’t flake off with handling.

Manufacturing & Quality Assurance Checklist

When evaluating a printing partner for yearbooks, inquire about their QA processes. Consistency is key when producing hundreds or thousands of copies.

- Signature Verification: ensuring pages are collated in the correct order before sewing.

- Pull Testing: Random samples should be tested to ensure the page pull-strength meets industry standards.

- Casing-in Precision: The book block must be centered perfectly within the hard case to ensure even margins (squares) and proper opening action.

- Endsheet Strength: The endsheets (the paper connecting the book block to the cover) must be a heavier stock (typically 140gsm+) to support the weight of the book block.

Buying Guide: Specifying Your Yearbook Order

To ensure accurate quotes and a final product that meets longevity expectations, include the following details in your Request for Quote (RFQ):

| Component | Recommended Specification |

|---|---|

| Style de reliure | Hardcover, Smyth Sewn (Section Sewn), Case Bound |

| Inner Paper | 157gsm Gloss or Matte Art Paper, Acid-Free |

| Cover Board | 2.5mm or 3mm High-Density Greyboard |

| Endsheets | 140gsm+ Uncoated Woodfree Paper (plain or printed) |

| Cover Finish | Anti-scratch Matte Lamination + Spot UV (optional) |

Questions fréquemment posées

What is the minimum order quantity (MOQ) for custom yearbooks?

MOQs vary by manufacturer, but offset printing—which offers the highest quality and best unit price—typically becomes viable at 500 copies. For smaller runs (e.g., 50-200 copies), digital printing may be used, though binding options should be carefully checked to ensure durability.

Why is Smyth sewn binding more expensive than perfect binding?

Smyth sewing involves an additional mechanical step where signatures are physically stitched before gluing. This requires specialized machinery and takes slightly longer, but it is the only way to guarantee a book that lays flat and lasts for decades.

Can I use recycled paper for yearbooks?

Yes, recycled options are available. However, ensure the recycled stock is certified acid-free and has sufficient whiteness and opacity for high-quality photo reproduction. Some lower-grade recycled papers may have a grayish tint that affects image vibrancy.

How long does the production process take?

For high-spec hardcover yearbooks, production typically takes 3 to 5 weeks after proof approval, depending on complexity and quantity. Shipping times must be added to this schedule, so planning early is essential.

Do you offer file checking services?

Professional printers usually include a pre-flight check to ensure artwork resolution, bleed, and color profiles (CMYK) are correct before plating. Always request a hard copy proof or a high-resolution digital proof to verify layout.

Ready to start your yearbook project?

Contact us today to discuss your specifications, request a material sample kit, or get a custom quote tailored to your school’s needs.