Choosing between hardcover and softcover book printing is one of the most critical decisions in the publishing production cycle. It impacts not only the manufacturing cost and retail price but also the durability, perceived value, and logistics of your project. For procurement managers and independent publishers alike, understanding the technical tradeoffs between these binding styles is essential for protecting margins and ensuring product quality.

This guide analyzes the structural, financial, and practical differences between hardcover (case bound) and softcover (paperback) printing to help you make an informed decision for your next print run.

The Core Difference: Construction and Materials

While the internal text block (the pages inside) is often printed similarly for both formats, the external construction differs significantly.

Couverture rigide (reliure cartonnée)

Hardcover books, technically known as case-bound books, are constructed using a rigid protective cover. This cover is made by wrapping a printed sheet (or cloth/leather material) around heavy-duty grayboard (typically 2mm to 3mm thick). The text block is attached to this case using endpapers.

Key structural features include:

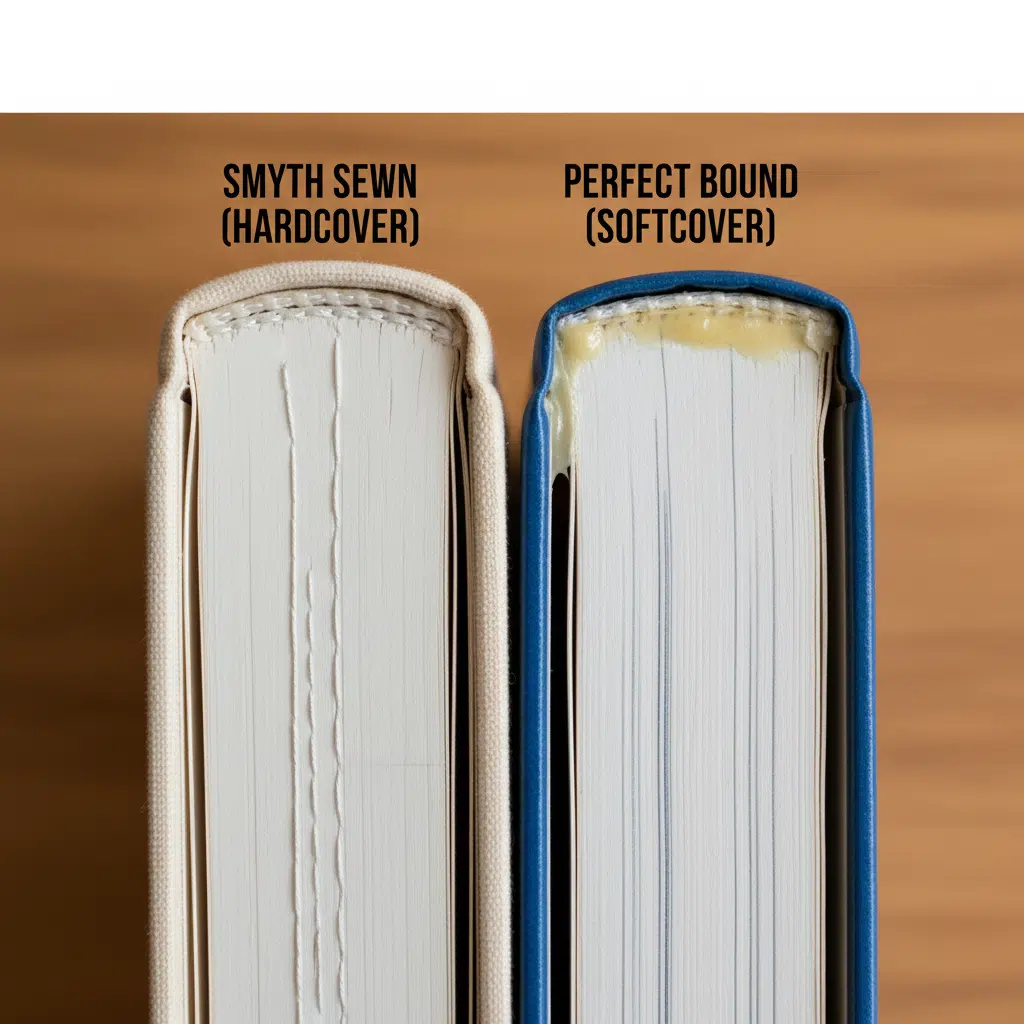

- Rigid Spine: The spine is stiff and does not flex when opened, protecting the binding glue.

- Smyth Sewing: High-quality hardcovers often feature Smyth sewn signatures (pages stitched together) before being glued into the case, allowing the book to lay flat.

- Pages de garde : These thick sheets of paper glue the text block to the inside of the hardcover board.

Softcover (Perfect Binding)

Softcover books use a flexible cover made from heavy cardstock, typically coated on one side (C1S) or both sides (C2S). The text block is glued directly to the spine of the cover using strong adhesives.

Key structural features include:

- Flexible Spine: The spine moves with the pages, though excessive flexing can sometimes crack the glue if standard EVA adhesive is used.

- Paper Weight: Covers usually range from 200gsm to 350gsm, depending on the book’s size and page count.

- Direct Adhesion: There are no endpapers; the first and last pages of the text block are adjacent to the inside cover.

For a deeper dive into why softcover might be the right choice for efficiency, you can read about the <a href="Cinq raisons de relier vos livres avec une reliure de poche“>five reasons to bind your books with paperback binding.

Strategic Comparison: Cost, Durability, and Logistics

When sourcing print services, three main factors usually drive the decision: budget, longevity, and distribution.

1. Production Costs

Hardcover production is more labor-intensive and material-heavy. It requires multiple steps: printing the wrap, cutting boards, case-making, and casing-in (marrying the book block to the case). Consequently, hardcover unit costs are typically 30% to 50% higher than softcovers, though this gap narrows on very large offset runs.

Softcovers are faster to produce. The cover is printed, laminated, and glued to the book block in a single automated pass on a perfect binder. This efficiency makes them the standard for mass-market titles.

2. Durability and Shelf Life

Hardcovers are built for longevity. The rigid board protects page corners from curling and the spine from breaking. They are the standard for libraries, textbooks, and keepsakes. If your project is a children’s book intended for repeated reading, the durability of a hardcover is often necessary. However, paper choice also plays a role here; see our guide on <a href="Cinq types de papier pour l'impression de livres pour enfants“>five types of paper for printing children’s books to pair the right stock with your binding.

Softcovers are durable enough for trade fiction, manuals, and annual reports, but they show wear faster. The corners of the cover may dog-ear over time, and the spine can crease if forced open aggressively.

3. Logistics and Shipping Weights

A factor often overlooked by buyers is shipping weight. Hardcovers are significantly heavier due to the grayboard and endpapers. For international shipping, this increased weight affects freight costs. Furthermore, hardcovers take up slightly more volume per unit, reducing the number of copies that fit on a pallet compared to softcovers.

When to Choose Hardcover vs. Softcover

Best Use Cases for Hardcover

- Premium Corporate Gifts: High-end yearbooks or company history books.

- Coffee Table Books: Art and photography books require the rigidity of a hardcover to support heavy coated paper.

- Journals and Planners: These products benefit from the sturdy writing surface a hardcover provides. If you are developing a stationery line, consider reading our guide on <a href="Fabrication de planificateurs et de journaux personnalisés : Guide des accessoires et des compléments“>custom planner and journal manufacturing to explore accessories like elastic bands and ribbons.

- Collector’s Editions: Limited runs meant to justify a higher retail price point.

Best Use Cases for Softcover

- Trade Fiction & Non-Fiction: The standard format for bookstores and airport shops.

- Instruction Manuals: Lightweight and flexible for easy handling in workshops or offices.

- Event Programs: Cost-effective for items with a short useful lifespan.

- Advance Reader Copies (ARCs): Cheap prototypes sent to reviewers before the final launch.

Technical Considerations: Spine Width and Paper Bulk

Regardless of the binding type, calculating the spine width accurately is crucial for your cover artwork. If the spine design is too wide or too narrow, the text will wrap onto the front or back cover, looking unprofessional.

Hardcover Spines: You must account for the thickness of the board and the “hinge” area where the cover opens. The calculation is more complex than softcover.

Softcover Spines: The width is determined strictly by the page count multiplied by the paper caliper (thickness). Understanding paper bulk is essential here. For a detailed explanation on getting this math right, refer to our article on <a href="Understanding Paper Bulk vs. GSM: How to Calculate Accurate Spine Widths“>Understanding Paper Bulk vs. GSM.

Binding Variations to Know

PUR vs. EVA Glue

For softcovers, ask your printer about PUR (Polyurethane Reactive) adhesive. Unlike traditional EVA glue, PUR is incredibly flexible and resistant to temperature extremes. It prevents pages from falling out even when the book is flattened. For hardcovers, sewn binding is superior to adhesive binding, ensuring the pages never detach from the spine.

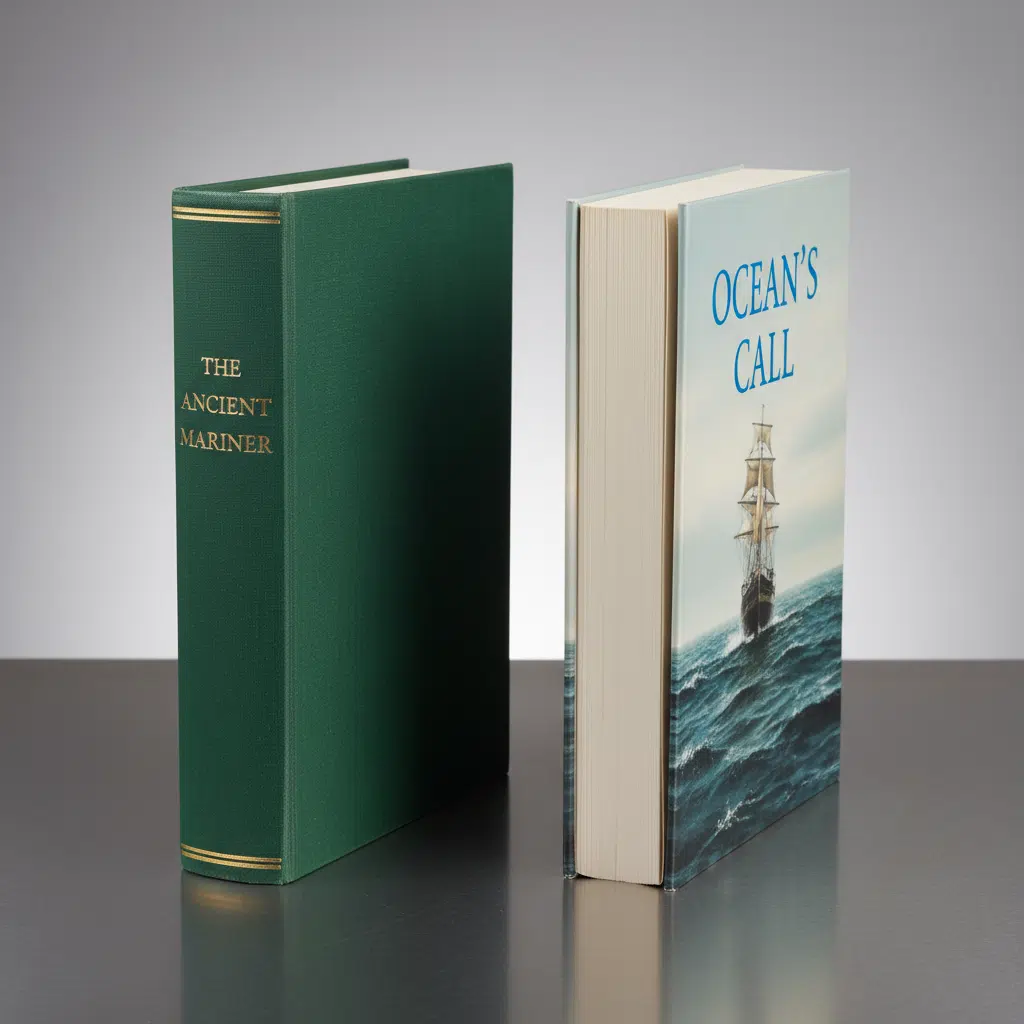

Dust Jackets vs. Printed Case (Image Wrap)

Hardcovers offer two main aesthetic paths:

- Image Wrap (Printed Case): The artwork is printed directly onto the paper that wraps the board. This is durable and modern.

- Cloth with Dust Jacket: The board is covered in linen or cloth (often with foil stamping), and a loose paper jacket wraps around it. This is traditional and highly perceived as “premium.”

Buying Guide: FAQs

What is the Minimum Order Quantity (MOQ)?

For custom offset printing, MOQs typically start at 500 to 1,000 units for both hard and softcovers to achieve a cost-effective unit price. Digital printing can accommodate shorter runs but with higher unit costs.

Can I mix hard and softcovers in one order?

Yes, this is common (split runs). However, it counts as two separate production setups. The interior pages can be printed in one run to save money, but the binding lines are completely different.

Which has a faster turnaround time?

Softcover is faster. Hardcover production requires drying time for the case-making glues and additional assembly steps. Expect hardcovers to add 5–10 days to the production timeline compared to softcovers.

Conclusion

The choice between hardcover and softcover printing ultimately balances budget against the intended user experience. Hardcovers offer unmatched durability and prestige, making them ideal for books intended to be kept for years. Softcovers offer efficiency, lower shipping costs, and portability, perfect for high-volume distribution.

At YBJ Printing, we specialize in high-quality offset printing for both formats, ensuring your project meets professional global standards.

Ready to start your project? Demander un devis / Obtenir un échantillon today to compare pricing for your specific specifications.