The Mechanics of Reusable Educational Publishing

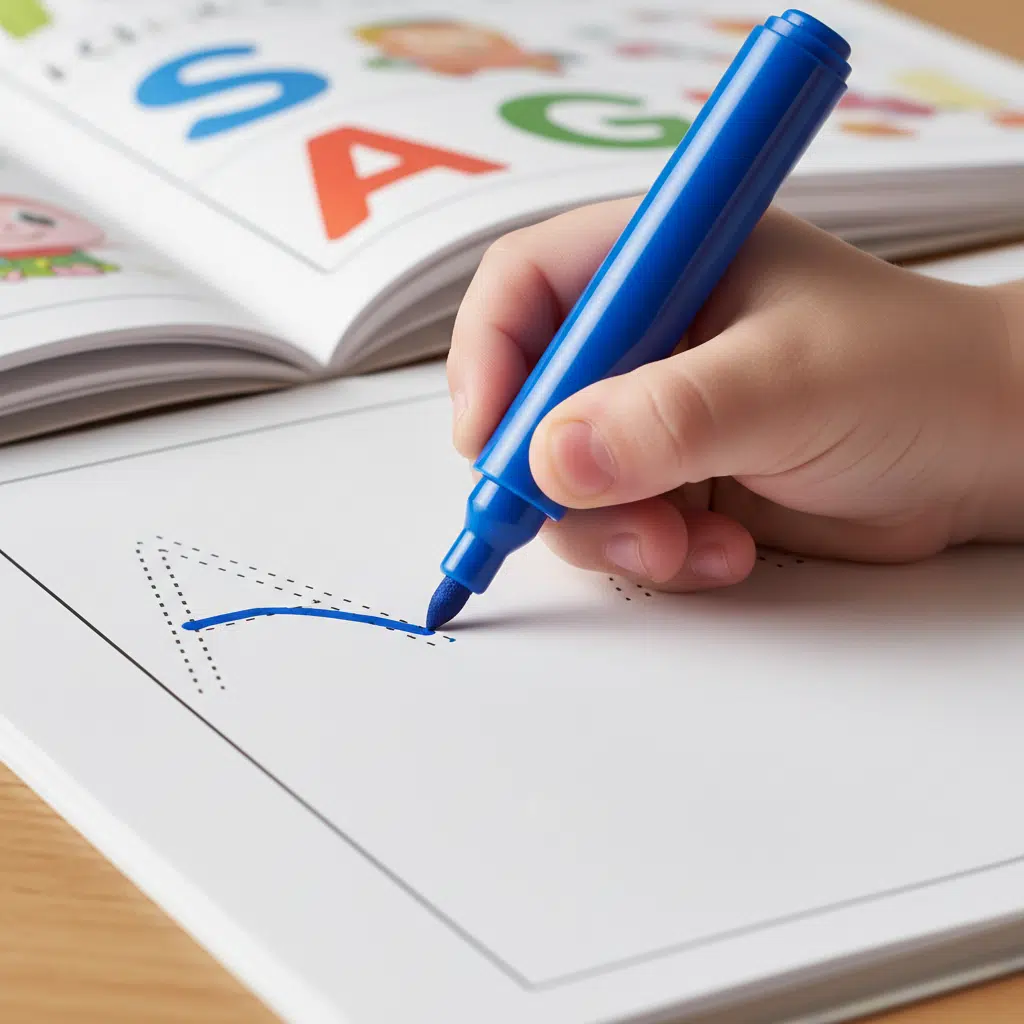

For educational publishers and toy brands, wipe-clean (dry-erase) activity books represent a high-value product category. Unlike standard workbooks that are consumed once, these products offer parents and educators the value of repeated practice—whether for handwriting, math drills, or creative drawing. However, manufacturing a durable wipe-clean book requires precise specifications regarding paper stock and lamination.

At YBJ Printing, we understand that the success of a dry-erase book relies entirely on the surface quality. If the lamination is too porous, ink "ghosts" (leaves a permanent stain). If the paper is too thin, it crumples under the pressure of a child’s writing. This guide outlines the technical manufacturing standards required to produce professional, durable wipe-clean activity books.

The Critical Component: Lamination Technology

The core feature of any wipe-clean book is its ability to resist ink absorption. This is achieved not through the paper itself, but through a specific plastic film application known as lamination.

Gloss vs. Matte Lamination for Dry-Erase

While matte lamination is popular for premium aesthetics in picture books, it is generally unsuitable for standard dry-erase markers. The texture of matte film creates microscopic valleys that trap ink pigments, making them difficult to wipe off completely.

- High-Gloss Lamination: This is the industry standard for wipe-clean surfaces. The smooth, non-porous finish allows the solvent-based ink of dry-erase markers to sit on top of the film without bonding. It ensures that ink can be wiped away with a cloth or tissue even days after writing.

- Specialized Dry-Erase Films: For premium projects, specific dry-erase polypropylene (OPP) or polyester (PET) films are used. These are chemically treated to enhance chemical resistance and prevent ghosting over long-term use.

Coating Thickness and Adhesion

For educational workbooks intended for young children, the lamination must be robust. We typically recommend a film thickness that balances flexibility with protection. If the film is too thin, it may scratch under the pressure of a marker tip; if too thick, it may cause the pages to curl. A standard thermal lamination process ensures the film bonds tightly to the paper fibers, preventing peeling at the corners—a common failure point in low-quality productions.

Paper Stock and Board Selection

Because these books are handled repeatedly and often subjected to vigorous wiping, standard text paper (e.g., 80gsm or 100gsm) is insufficient. It lacks the structural integrity to withstand the friction of wiping and the pressure of writing.

Recommended Paper Weights

To ensure durability, the substrate must be rigid enough to lay flat and resist tearing.

- Standard Activity Pages: We recommend a minimum of 250gsm to 350gsm C2S (Coated Two Sides) art card. This weight provides a card-stock feel similar to a high-quality postcard or business card.

- Heavy-Duty Board Books: For toddlers, mounting the printed sheet onto greyboard (creating pages 1mm–2mm thick) is ideal. This "board book" construction is virtually indestructible during normal play.

Grain Direction and Flatness

Paper grain direction is critical in manufacturing wipe-clean books. If the grain runs perpendicular to the spine, the pages may resist turning or curl aggressively after lamination. Experienced manufacturers ensure the grain direction aligns with the binding to ensure the book opens easily and lays relatively flat.

Binding Styles for Usability

A wipe-clean book is useless if it snaps shut while a child is trying to write in it. The binding method dictates the user experience.

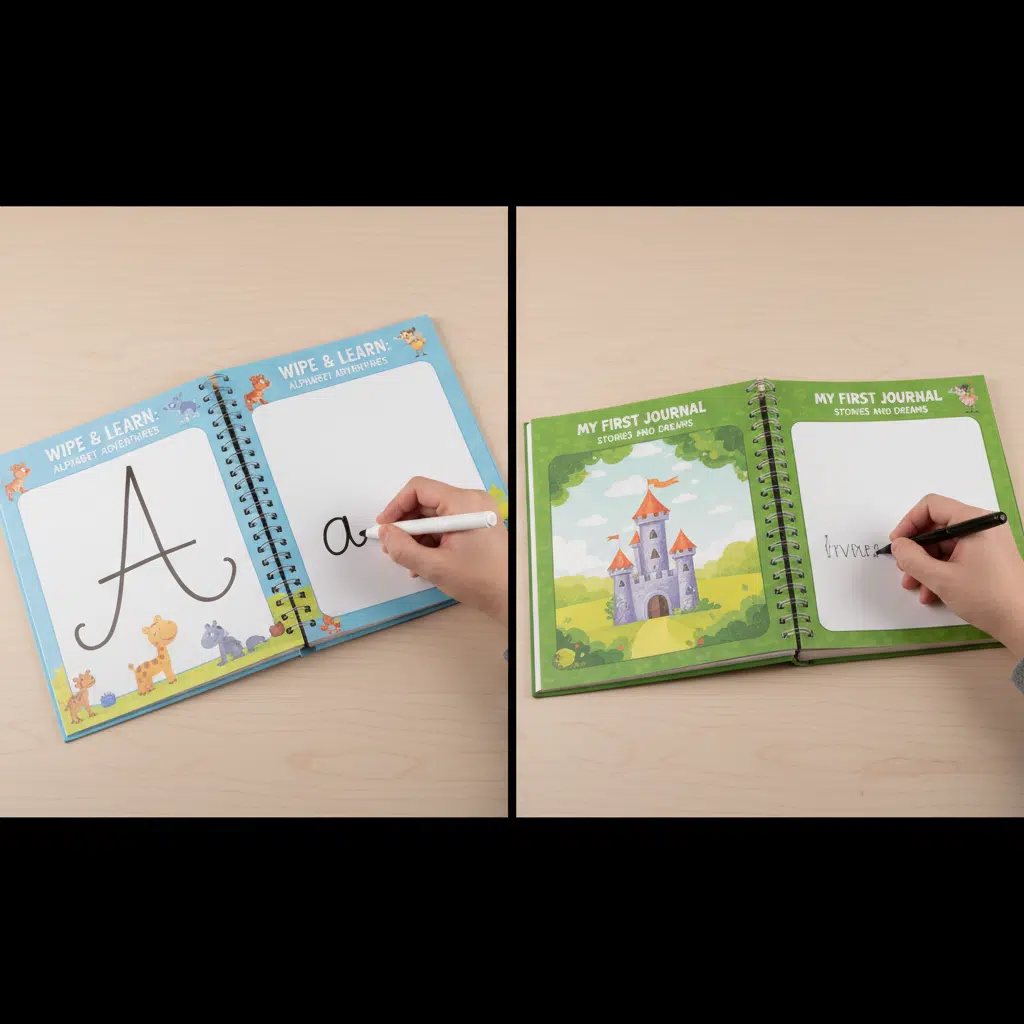

Wire-O and Spiral Binding

This is the most functional option for workbooks.

- Pour : Allows the book to lay completely flat (180 degrees) or fold back on itself (360 degrees). This provides a stable writing surface on a table or a child’s lap.

- Safety Note: For children’s products, we recommend using a concealed Wire-O binding (where the wire is hidden inside the spine cover) or ensuring the wire ends are securely tucked to prevent scratching.

Piqûre sellier

Suitable for thinner booklets (typically under 32 pages). While cost-effective, saddle-stitched books (stapled spine) do not lay as flat as Wire-O books, which can be frustrating for handwriting practice. It is best reserved for promotional items or thinner supplements.

Manufacturing Quality Control (QC) for Educational Books

When producing educational materials for international markets, strict QC protocols are non-negotiable.

- The Wipe Test: A crucial QC step involves writing on sample sheets with standard dry-erase markers, leaving the ink for 24 to 48 hours, and then attempting to erase it. The surface must wipe clean without leaving faint shadows (ghosting).

- Safety Compliance: Since these products are often categorized as toys or educational materials for children, the lamination, inks, and binding materials must comply with safety standards such as EN71 (Europe) or ASTM F963 (USA). This ensures the materials are free from heavy metals and phthalates.

- Marker Compatibility: If you are including a marker with the book, it is vital to source markers that are chemically compatible with the lamination film selected. We can assist in sourcing compliant markers to package as a complete set.

Buying Guide: Key Specifications for Your RFQ

To receive an accurate quote for custom wipe-clean book manufacturing, include the following details in your request:

- Taille : Common sizes are A4, 8.5" x 11", or square formats.

- Page Count: Remember that thick paper adds bulk quickly.

- Material: Specify "300gsm C2S with Gloss Lamination on both sides."

- Binding: Wire-O (color of wire), Spiral, or Board Book.

- Accessoires : Do you need a marker included? Should it be glued to the cover in a blister pack or inserted in a re-sealable bag?

- Quantity (MOQ): Custom lamination and die-cutting typically require an MOQ of 500–1,000 units to be cost-effective.

Summary Table: Paper vs. Application

| Target Age Group | Recommended Material | Style de reliure | Best Use Case |

|---|---|---|---|

| Preschool (3-5 yrs) | Mounted Greyboard (1-2mm) | Board Book / Cased-in | Basic motor skills, durability focus |

| Primary (5-8 yrs) | 300gsm C2S Cardstock | Wire-O / Spiral | Handwriting, math, complex activities |

| Travel/Portable | 350gsm Cardstock | Spiral (Top or Side) | Bingo, travel games, mazes |

Questions fréquemment posées

Can I use matte lamination if I want a modern look?

It is risky. Standard matte lamination holds onto ink residue. If a matte look is essential for your brand, we must use a specialized, high-cost anti-scuff matte film designed specifically for dry-erase, but gloss remains the safest and most functional choice.

Do you provide the dry-erase markers?

Yes, we can source safety-tested markers (with or without erasers on the cap) and package them with your books. We can also provide custom blister packaging to attach the marker to the cover.

What is the lead time for these books?

Due to the extra steps of lamination and drying time required to ensure a perfect cure, lead times are slightly longer than standard books. Typically, production takes 20–30 days after proof approval, depending on quantity and assembly complexity.

Ready to produce high-quality educational materials? Demande de devis today to discuss your wipe-clean book project and get a sample pack to test our lamination quality.