For independent publishers and retail brands, the physical book is often the primary touchpoint with the customer. However, the journey from the warehouse to the reader’s hands is fraught with logistical risks. Damaged corners, scuffed covers, and crushed spines result in returns and diminished brand value. Simultaneously, the “unboxing” phenomenon has turned packaging into a marketing channel in its own right.

Effective custom book packaging must balance two competing priorities: structural integrity for shipping and aesthetic appeal for the retail or unboxing experience. This guide explores the technical specifications, material choices, and design finishes available for creating branded book packaging that protects inventory and elevates your brand.

Defining the Scope: Mailers vs. Retail Boxes

Before selecting materials, it is critical to distinguish the primary function of the packaging. Are you shipping single units directly to consumers (DTC), or are you designing a shelf-ready box set for retail distribution?

1. Corrugated Book Mailers (DTC Focus)

Corrugated mailers are designed to withstand the rigors of courier networks. They are typically constructed from E-flute or B-flute corrugated board, which offers excellent crush resistance while remaining lightweight to minimize shipping costs.

- Roll-End Tuck-Front (RETF): The industry standard for subscription boxes and premium book shipments. The double-walled sides provide extra protection for book corners.

- Variable Depth Mailers: Cross-shaped folders that wrap around the book, allowing for variable spine widths. These are cost-effective but offer less “premium” presentation than RETF boxes.

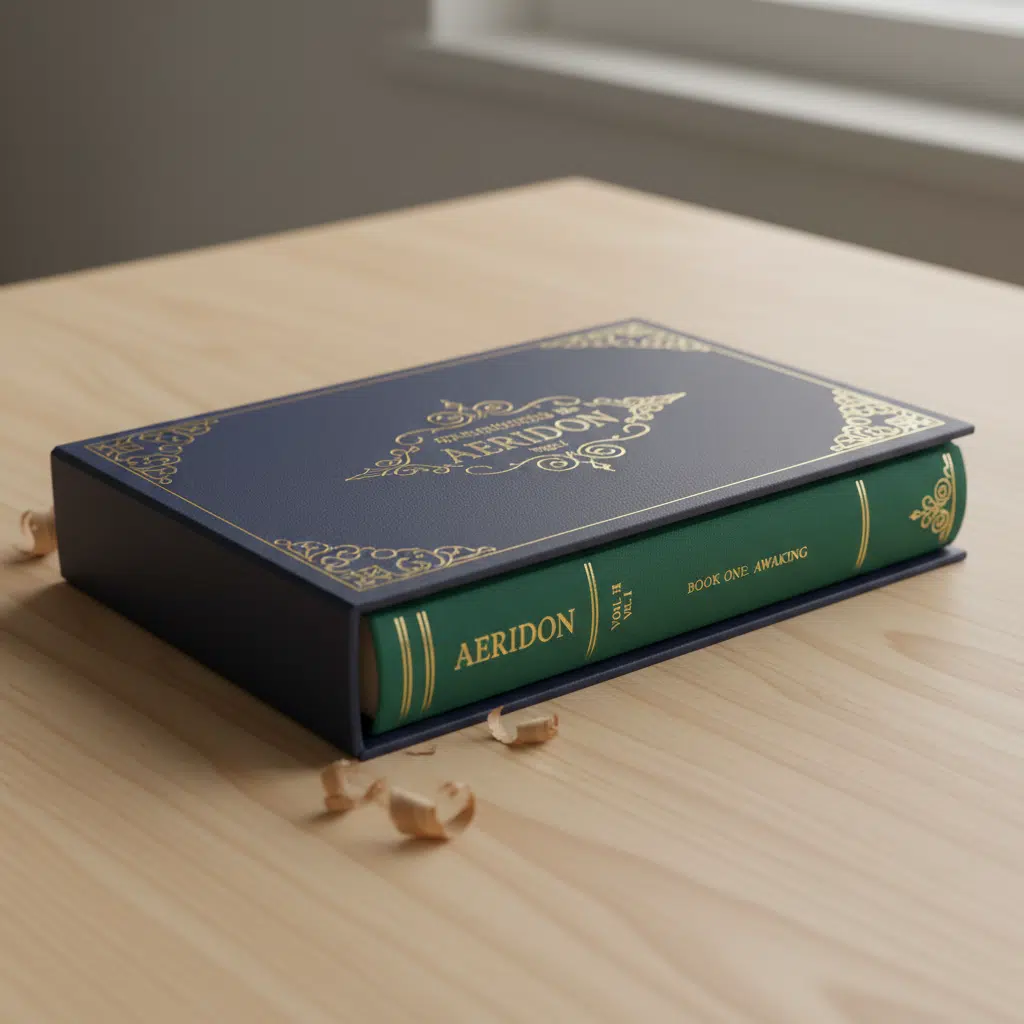

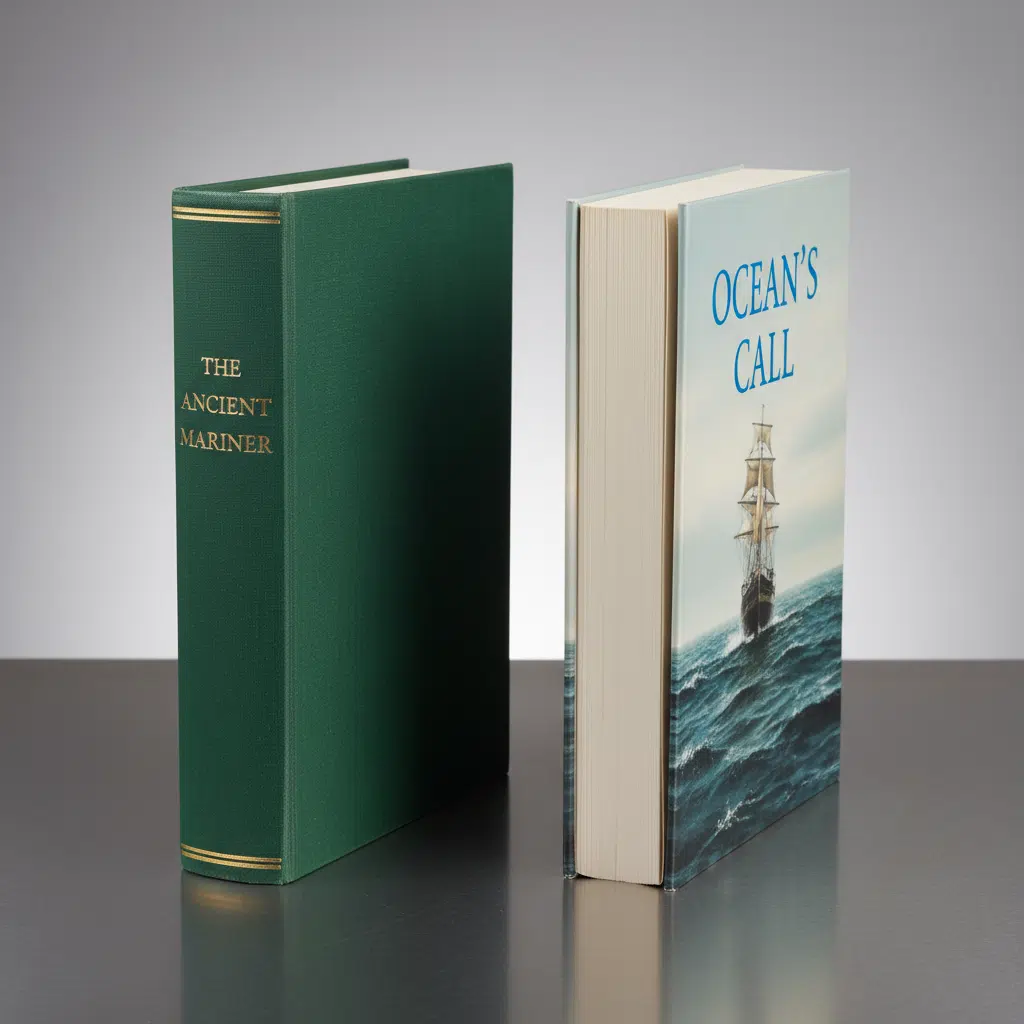

2. Rigid Boxes & Slipcases (Retail & Luxury Focus)

Rigid boxes (setup boxes) are not designed to be shipping containers on their own; they usually require an outer corrugated shipper. They are constructed from high-density greyboard wrapped in printed paper (art paper or specialty texture). These are ideal for:

- Limited Edition Sets: High-value collectors’ items.

- Multi-Volume Box Sets: Holding a series of books together on a shelf.

- Corporate Gifts: Presentation kits including a book and branded merchandise.

Material Specifications and Structural Design

Selecting the right substrate is the foundation of effective packaging. The choice depends on the weight of the book and the desired shelf appeal.

Rigid Board Thickness

For slipcases and luxury boxes, the thickness of the greyboard determines the structural rigidity. Common specifications include:

- 1.5mm – 2mm (approx. 1000gsm – 1200gsm): Standard for most single-book slipcases.

- 2.5mm – 3mm (approx. 1600gsm+): Required for heavy hardcover encyclopedias, art books, or multi-book sets to prevent bowing.

Corrugated Flute Types

For shipping boxes, the flute refers to the wave-shaped paper arch between the linerboards:

- E-Flute (1.6mm): Fine flute, excellent surface for high-quality printing (litho-lamination). Good for smaller, lighter books.

- B-Flute (3.2mm): Thicker and stronger. Better for heavy hardcovers or bulk shipments.

Comparison: Corrugated vs. Rigid

| Fonctionnalité | Corrugated Mailer | Rigid Box / Slipcase |

|---|---|---|

| Primary Use | Shipping / Protection | Presentation / Storage |

| Material Cost | Low to Medium | High |

| Shipping Volume | Ships flat (Space-saving) | Ships assembled (High volume) |

| Protection Level | High impact resistance | High structural rigidity |

| Printing Surface | Direct print or Litho-lam | Wrapped art paper (Premium) |

Printing Finishes and Branding Options

Once the structure is defined, the exterior finish transforms the packaging from a container into a brand asset. Industrial printing capabilities allow for extensive customization.

Lamination

Lamination is mandatory for most rigid boxes and coated corrugated boxes to prevent cracking on the fold lines and to protect the ink.

- Matte Lamination: A sophisticated, non-reflective finish that resists fingerprints.

- Gloss Lamination: High vibrancy, making colors pop.

- Soft-Touch Lamination: A velvet-like tactile finish often used for premium editions.

Finitions spéciales

- Spot UV : A high-gloss clear polymer applied to specific areas (e.g., the book title or logo) to create contrast against a matte background.

- Marquage à la feuille : Using heat and pressure to apply metallic foil (gold, silver, holographic). This is highly effective for title text on slipcases.

- Debossing/Embossing: Physically pressing textures into the board for a 3D effect.

Structural Engineering: Inserts and Fit

A common failure in book packaging is poor fit. If a book can move inside the box, the corners will inevitably sustain damage during transit. The internal dimensions must be calculated with precision.

Calculating Dimensions

Always specify Inner Dimensions (ID) when communicating with a manufacturer. A standard tolerance gap is roughly +2mm to +3mm on each side of the book to allow for easy insertion without friction damage, but tight enough to prevent sliding.

Custom Inserts

For presentation boxes holding a book plus other items (e.g., a pen, bookmark, or USB drive), custom inserts are required:

- Paper Pulp / Cardboard: Eco-friendly and cost-effective.

- EVA Foam: High-density foam providing the ultimate luxury feel and shock absorption. Can be die-cut to the exact shape of the book.

Manufacturing & Buying Guide

Procuring custom packaging involves several logistical considerations that impact cost and lead time.

Minimum Order Quantities (MOQs)

Due to the setup costs of offset printing plates and die-cutting molds, industrial manufacturers typically set MOQs. While digital printing allows for smaller runs, true custom packaging (especially rigid boxes) becomes cost-effective at volumes of 500 to 1,000 units or more.

Logistics: Flat vs. Assembled

Rigid boxes usually ship assembled, meaning you are paying to ship mostly air. This can significantly increase freight costs. Collapsible rigid boxes (which ship flat and use magnetic closures and adhesive strips to assemble) are a modern solution that balances luxury with logistical efficiency.

Sampling

Before committing to a full production run, always request a physical sample. There are two types:

- White Dummy: An unprinted structural sample to test size, paper quality, and fit.

- Digital Proof / Pre-production Sample: A printed sample to verify color accuracy and finishes.

Conclusion

Custom packaging is an investment in brand perception and product safety. Whether you require a robust corrugated mailer for global distribution or a gold-foiled slipcase for a special edition, understanding the materials and manufacturing processes ensures you get the right solution for your budget.

At YBJ Printing, we specialize in high-quality paper and packaging solutions tailored to international standards. Our team can guide you through the structural design and material selection to ensure your books arrive in pristine condition.

Questions fréquemment posées

What is the difference between a slipcase and a clamshell box?

A slipcase is open on one side (the spine usually shows). A clamshell box (or Solander box) opens like a book and fully encloses the contents, offering superior protection against dust and light.

How do I supply artwork for custom boxes?

Artwork should be supplied on a vector-based dieline template (usually provided by the manufacturer) in PDF or AI format, with at least 3mm bleed and fonts outlined.

Can you print on the inside of the box?

Yes. Double-sided printing is a popular trend for unboxing experiences. For corrugated boxes, this often involves litho-lamination on both sides or flexographic printing on the interior.

Are these packaging options eco-friendly?

Yes. Most rigid and corrugated boards are made from recycled pulp. Using soy-based inks and avoiding lamination (or using biodegradable laminates) can further enhance sustainability.

Ready to upgrade your book packaging?

Contact YBJ Printing today to discuss your project requirements, request a dieline template, or get a custom quote.