The Unique Engineering Behind Religious Text Production

Printing a Bible—or any high-page-count religious text—is widely considered one of the most technically demanding tasks in the book manufacturing industry. Unlike standard trade paperbacks or marketing brochures, Bibles require a delicate balance between extreme portability and massive content volume. A standard Bible may contain over 1,200 pages yet must remain thin enough to be carried comfortably to services.

For publishers and religious organizations, sourcing bible printing services is not just about finding a printer; it is about finding a manufacturing partner capable of handling ultra-thin substrates (often called India paper) and executing complex finishing techniques like edge gilding and leather binding. This guide explores the technical intricacies of producing high-quality religious books and what procurement managers need to know to ensure a durable, elegant final product.

Understanding Bible Paper: Opacity and Tension Control

The defining feature of a high-quality Bible is the paper. Standard book paper typically ranges from 60gsm to 80gsm (grams per square meter). In contrast, Bible paper (or India paper) usually falls between 28gsm and 40gsm.

The Technical Challenges of Thin Paper

Printing on paper this thin introduces significant manufacturing hurdles:

- Show-Through (Opacity): The thinner the paper, the more likely text from the reverse side will be visible. Premium Bible paper is engineered with high opacity, often using titanium dioxide fillers to block light transmission while maintaining a low weight.

- Tension Management: On high-speed offset presses, thin paper is prone to tearing or wrinkling. Specialized tension control systems are required to feed the paper smoothly without snapping the web or causing registration errors.

- Ink Absorption: Because the paper is thin, heavy ink coverage can cause saturation issues. Pre-press teams must adjust color density (total ink limit) to prevent bleed-through or wavy pages.

Gilded Edges: Aesthetics Meets Function

Gold or silver edging on Bibles is not merely decorative; historically, it served a functional purpose. Gilded edges protect the paper from dust, moisture, and yellowing over decades of use. Today, it remains a hallmark of premium religious publishing.

The Gilding Process

Applying metallic foil to the edges of a book block is a precision process:

- Sanding: The edges of the book block must be sanded perfectly smooth. Even microscopic paper fibers can disrupt the foil application.

- Application: Heat and pressure are used to bond the metallic foil to the paper edges.

- Art Gilding (Salmoning): For ultra-premium editions, a red dye is applied to the edges before the gold foil. When the book is closed, it looks gold; when open, the edges appear reddish. This requires additional processing steps and higher minimum order quantities (MOQs).

Binding Styles for Longevity

A Bible is intended to be opened thousands of times over many years. Standard adhesive binding (perfect binding) is rarely sufficient for a 1,000+ page book, as the spine will eventually crack, and pages will fall out.

Smyth Sewing (Section Sewing)

The industry standard for Bibles is Smyth sewing. In this process, folded signatures (groups of pages) are stitched together with thread before being glued into the spine. This offers two critical benefits:

- Lay-Flat Ability: The book can stay open on a pulpit or table without snapping shut.

- Durability: The mechanical thread bond is far stronger than glue alone.

Cover Materials

Buyers typically choose between three tiers of cover materials:

- Genuine Leather: The most durable and expensive option (e.g., calfskin, goatskin). It develops a patina over time and is flexible.

- Bonded Leather: A composite material made from leather fibers. It offers the look and smell of leather at a lower cost but is less flexible.

- PU (Polyurethane) / Faux Leather: A popular choice for mass-market Bibles. High-quality PU can mimic the soft feel of leather and allows for extensive thermal embossing (heat stamping) of designs.

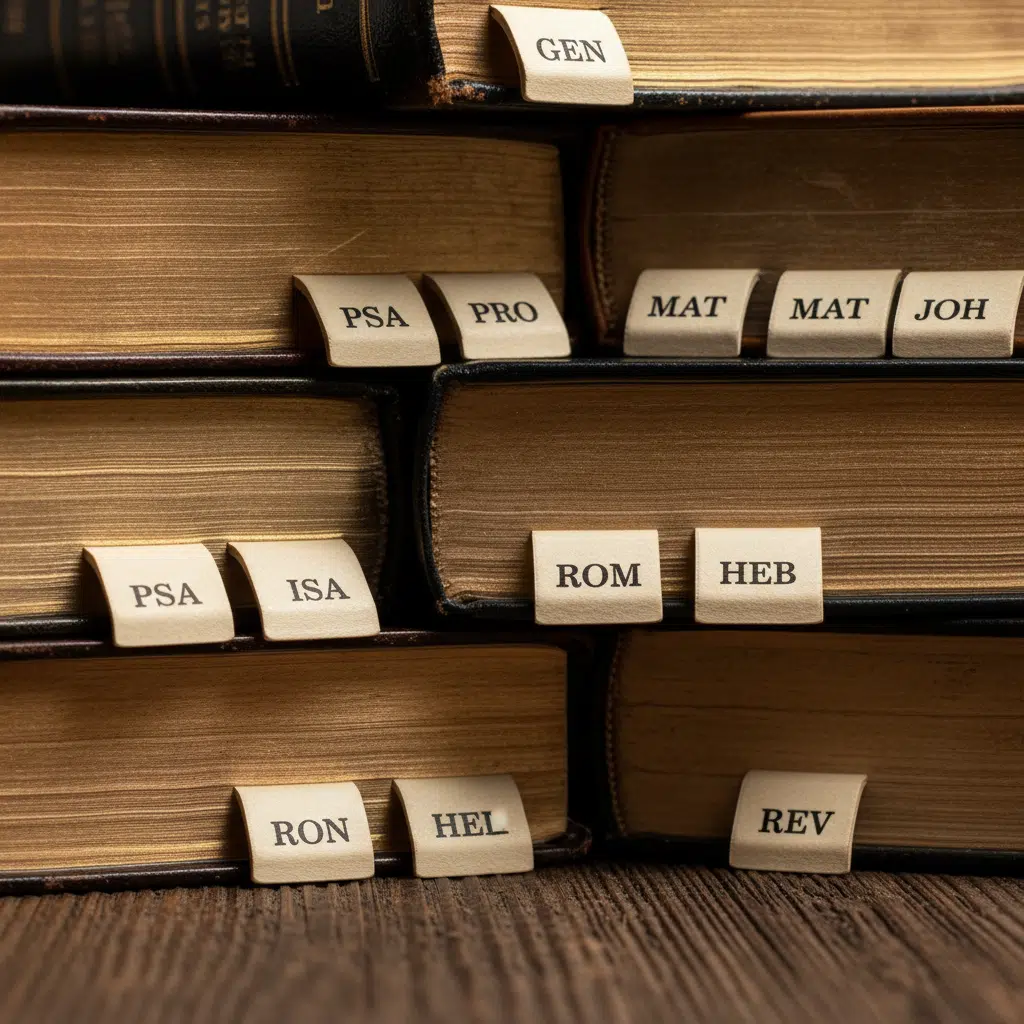

Thumb Indexing and Ribbons

Navigation is key for religious texts. Thumb indexing involves cutting semi-circular notches into the side of the book block and applying labeled tabs (e.g., “Gen”, “Exo”) to help readers locate chapters quickly. This is a post-binding operation that requires specialized die-cutting machinery to avoid damaging the delicate thin paper.

Similarly, ribbon markers are inserted during the casing-in process. High-end Bibles may require two or three satin ribbons, which must be heat-sealed at the ends to prevent fraying.

Buying Guide: Key Considerations for Publishers

When commissioning a print run for Bibles, consider the following specifications to ensure accurate quotes and quality results.

Minimum Order Quantities (MOQs)

Due to the setup time required for thin paper tensioning and custom gilding, MOQs for custom Bibles are typically higher than standard books. Expect MOQs starting around 1,000 to 2,000 units, though this varies based on material availability.

File Preparation

- Margins: Thin paper moves slightly more during production. Ensure safety margins are generous (at least 10-15mm) to prevent text from being trimmed or lost in the gutter.

- Fonts: Avoid extremely fine serif fonts on Bible paper, as ink spread (dot gain) can reduce legibility.

Frequently Asked Questions

What is the best paper weight for a compact Bible?

For a truly compact “pocket” Bible, 28gsm to 30gsm paper is ideal. For a standard pew Bible where durability is more important than thickness, 40gsm to 50gsm is recommended.

Can you print full-color illustrations on Bible paper?

Yes, but it requires careful color management. Because the paper is translucent, images on one side can interfere with text on the other. It is often better to print illustrations on slightly thicker, coated inserts (tipped-in pages) distributed throughout the book.

What is the difference between gold gilding and sprayed edges?

Gilding uses a metallic foil applied with heat for a shiny, reflective finish. Sprayed edges use ink or paint, resulting in a matte color. Gilding is more durable and traditional for Bibles.

How long does production take?

Bible printing typically has a longer lead time than standard books—often 4 to 8 weeks after proof approval—due to the complex binding, drying times for glues, and manual finishing steps like ribbon insertion.

Partner with Experts in Religious Printing

Producing a Bible is a convergence of tradition and industrial precision. Whether you need a leather-bound heirloom edition or a durable hardcover for pew use, YBJ Printing offers the specialized capabilities required to handle thin paper and complex bindings with care.

Ready to start your project? Contact our team today to discuss specifications, request paper samples, or get a custom quote for your religious book printing needs.