Turning Books into Collectible Art Objects

For fiction publishers and Kickstarter creators, the book is no longer just a vessel for text; it is a physical object of desire. Driven by the visual demands of social media communities like “BookTok” and the tier-based rewards of crowdfunding campaigns, special edition finishes have moved from niche luxury to essential marketing tools.

Among these finishes, sprayed and stenciled book edges have emerged as the most requested feature for limited runs and collector sets. While traditional manufacturing focused solely on the cover and spine, modern custom book manufacturing now treats the three outer edges of the book block as a canvas.

This guide explains the industrial processes behind these edge finishes, the technical requirements for artwork, and how to source them effectively for your next print run.

Defining the Techniques: Sprayed vs. Stenciled vs. Digital

Buyers often use terms interchangeably, but for a manufacturer, the production methods differ significantly. Understanding these differences helps in defining specifications and managing costs.

1. Solid Sprayed Edges

This is the application of a single, solid color to the edges of the book block.

- Process: Books are clamped tightly to prevent ink migration (bleeding) onto the page surfaces. A fine mist of ink is applied, usually via an airbrush or automated spray booth.

- Best For: Matching a cover’s primary brand color or creating a stark contrast (e.g., black edges on a white cover).

- Color Matching: Printers typically require a Pantone (PMS) code to ensure the edge color matches the cover design elements exactly.

2. Stenciled and Digitally Printed Edges

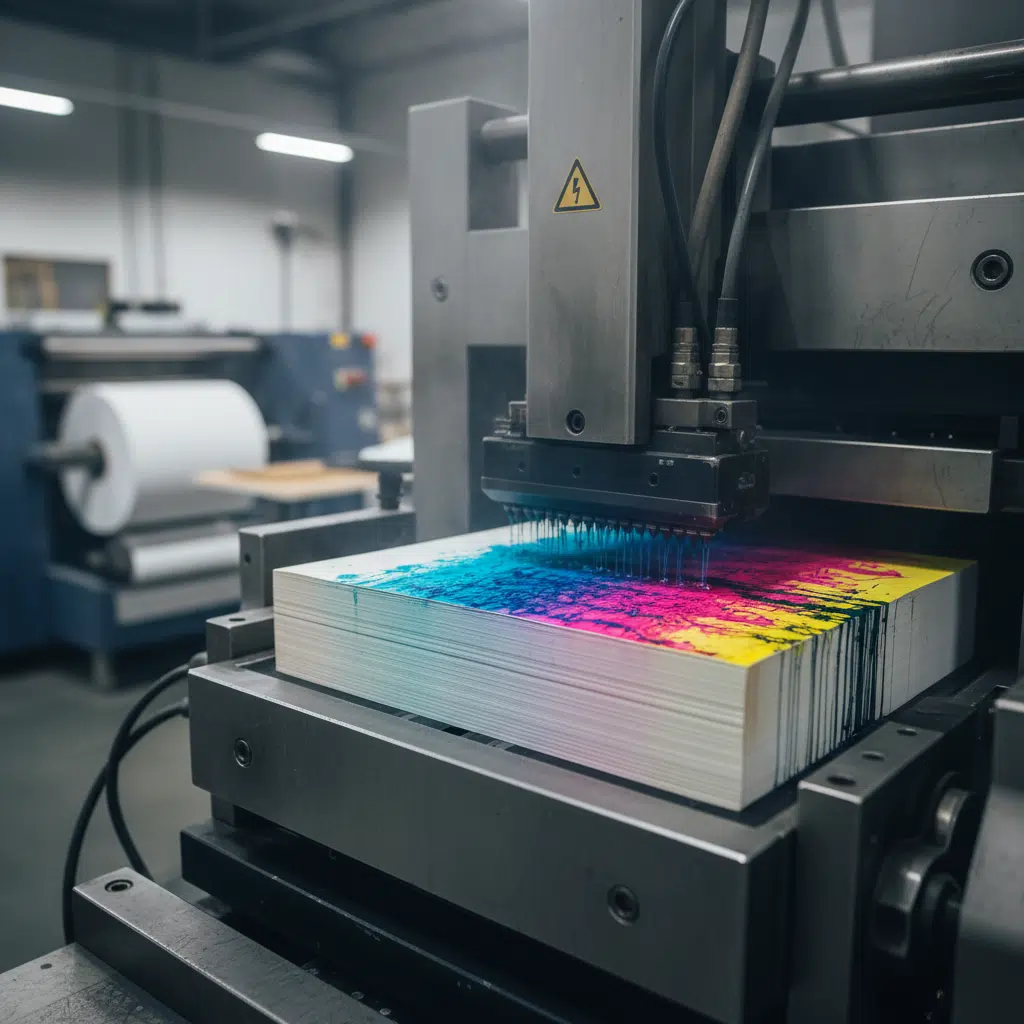

This technique allows for patterns, text, or illustrations to appear on the edges. While historically done with physical stencils and spray paint, modern high-volume manufacturing utilizes digital inkjet technology.

- Process: An industrial inkjet print head passes over the clamped book block, depositing CMYK ink to create high-resolution images. This allows for continuous designs that can span across the spine or wrap around all three edges.

- Best For: Fantasy maps, floral vines, character art, or hidden text that is only legible when the book is closed.

- Design Flexibility: Unlike physical stencils, digital edge printing handles gradients and complex details without the limitations of cut-outs.

3. Gilded and Foiled Edges

Gilding involves applying a thin layer of metallic foil (gold, silver, holographic) to the edges using heat and pressure.

- Process: The edges are sanded perfectly smooth, a size (adhesive) is applied, and the foil is hot-stamped onto the block.

- Best For: High-end luxury editions, religious texts, and prestige classics.

- Durability: Foil offers excellent protection against dust and moisture but is generally more expensive than ink spraying.

Technical Specifications for Designers

To ensure a successful production run, artwork for book edges must be prepared differently than cover files. Improper file preparation is the leading cause of production delays.

Artwork Orientation and Bleed

When designing for digitally printed edges, the artwork is typically laid out as three separate rectangles (Top, Fore-edge, Bottom) or one continuous strip if the design wraps around.

- Bleed: You must include at least 3mm–5mm of bleed on all sides of the edge design. The printer trims the book block before printing, but slight shifts can occur.

- Resolution: Images must be 300 DPI or higher. Low-resolution images will look pixelated on the rough texture of paper edges.

Paper Compatibility

The type of paper used for the book’s interior affects the edge printing quality.

- Uncoated Woodfree Paper: The industry standard for novels. It absorbs ink well, resulting in matte, deep colors. However, highly porous paper requires careful ink regulation to prevent bleeding into the margins.

- Coated Art Paper: Ink sits on top of the surface, creating sharper images. However, drying times are longer, and there is a higher risk of smudging if not properly cured.

Manufacturing Challenges and Quality Control

Producing sprayed edges involves distinct risks that your printing partner must manage. When evaluating samples or establishing quality criteria, look for the following:

1. Bleeding (Seepage)

Ink should never migrate more than a fraction of a millimeter onto the face of the page. If you open the book and see jagged lines of color encroaching on the text margins, the clamping pressure was insufficient or the ink viscosity was incorrect.

2. Sticking Pages (Blockage)

If books are unclamped or packed before the ink is fully dry, the pages may stick together. A high-quality production line includes a “fanning” or separation stage, or uses quick-dry UV inks to prevent this.

3. Color Consistency

For series or large print runs, consistency is vital. The edge color of the first book off the line must match the last. Professional printers use spectrophotometers to ensure the sprayed color remains within acceptable Delta E tolerances.

Buying Guide: MOQ and Cost Factors

For Kickstarter creators and independent publishers, economics are key. Here is how edge finishing impacts the bottom line.

Minimum Order Quantities (MOQ)

While digital printing has lowered the barrier to entry, setting up edge-printing machinery takes time.

- Typical MOQ: Many industrial printers require an MOQ of 500 to 1,000 units for custom edge printing.

- Unit Cost: Expect edge printing to add a noticeable percentage to the unit cost, primarily due to the manual handling required (loading and unloading book blocks).

Lead Times

Edge printing is a post-production process. It happens after the book block is bound and trimmed but often before casing-in (depending on the machine). Always add 1–2 weeks to your standard production timeline to account for spraying, drying, and QC.

Frequently Asked Questions

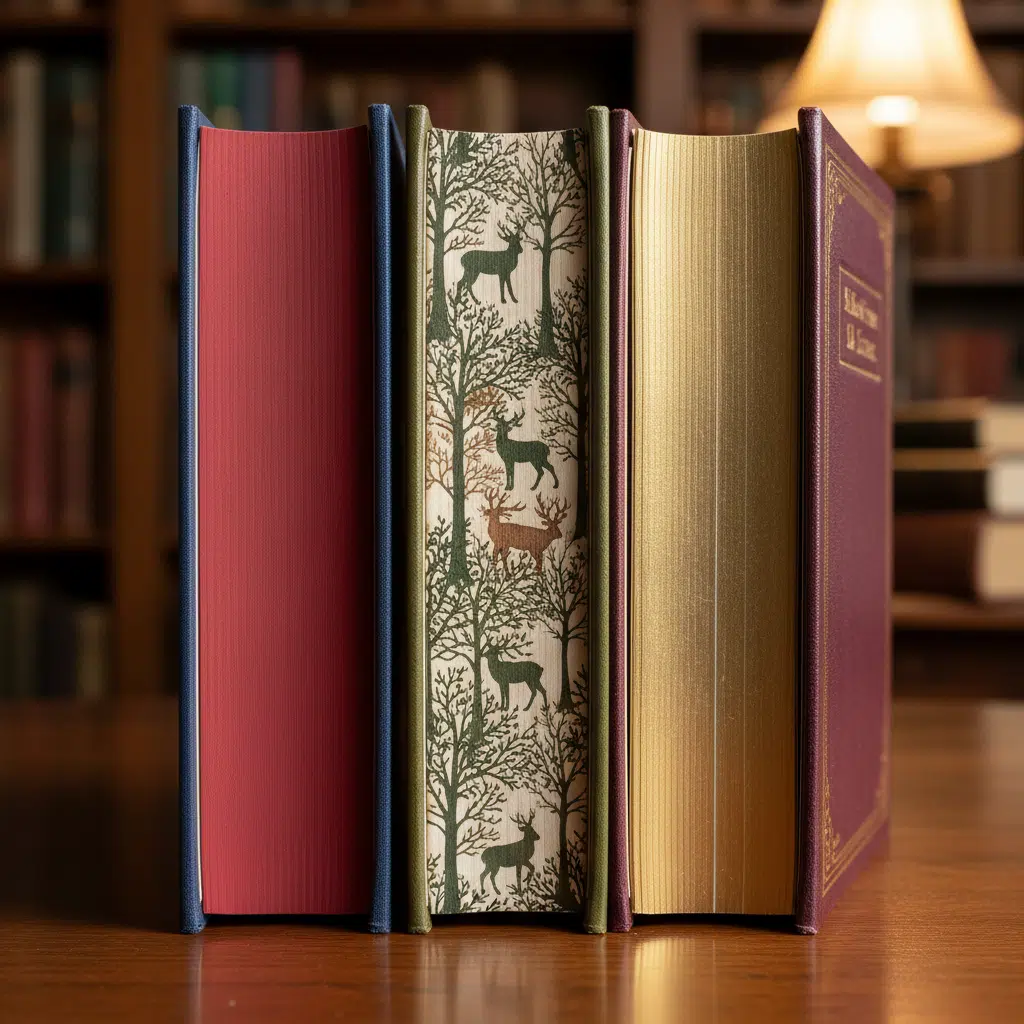

Can you print a continuous image across a book series?

Yes. If you have a trilogy, we can print a segmented image on the spines or fore-edges so that when the books are shelved together, they form a single large image. This requires precise calculation of the spine widths.

Will the edge ink fade over time?

Most industrial edge inks are UV-resistant, but like all printed materials, direct sunlight can cause fading over years. Ideally, books should be shelved away from direct window light.

Can softcover (paperback) books have sprayed edges?

Yes, sprayed edges are possible on paperbacks. However, because paperback covers are usually flush with the book block, there is a risk of ink getting on the cover edge. Hardcovers are generally preferred for this finish because the cover overhang (squares) protects the edges.

Do I need to provide a physical sample?

While not strictly necessary, providing a physical color swatch or a hard proof is helpful. However, most workflows rely on digital proofs and Pantone references.

Start Your Custom Edition Project

Sprayed and stenciled edges transform a standard reading copy into a premium collector’s item. Whether you are fulfilling a crowdfunding stretch goal or launching a special anniversary edition, YBJ Printing provides the technical expertise to execute complex edge designs with precision.

Ready to elevate your book project? Contact our team today to discuss your design specifications and request a quote for custom edge printing.