Strategic Value of Branded Stationery in B2B Markets

For corporate buyers, marketing agencies, and office supply distributors, a custom notebook is more than just paper and binding. It is a tangible brand asset. Unlike digital ads that disappear in seconds, a high-quality physical notebook sits on a client’s desk for months, reinforcing brand recall every time it is used.

However, the gap between a generic “off-the-shelf” notebook and a truly custom-manufactured product is significant. Professional custom notebook printing allows for complete control over specifications—from the tactile feel of the cover material to the opacity of the inner pages. This guide covers the technical and logistical factors procurement officers and brand managers must consider when sourcing custom notebooks for corporate use.

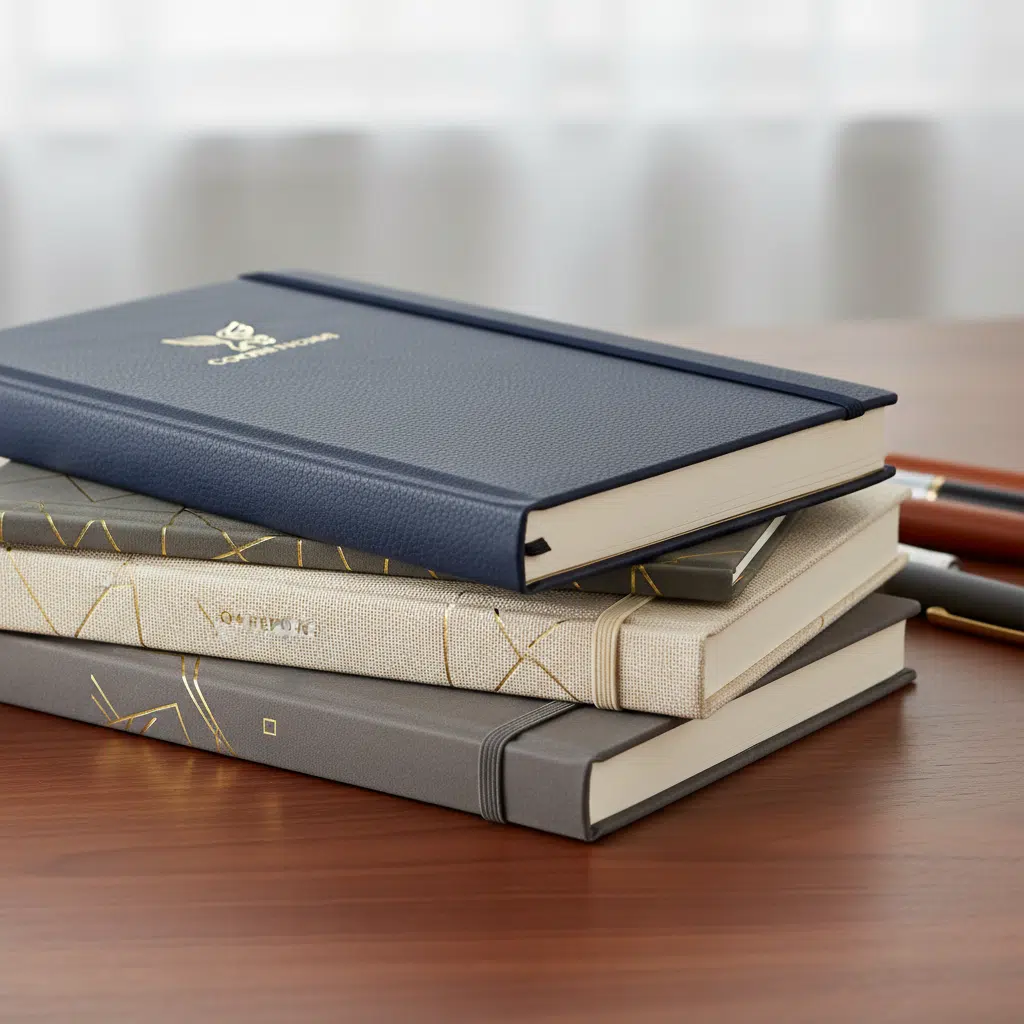

Selecting the Right Cover Material

The cover sets the first impression and dictates the durability of the product. When ordering from a manufacturer, you typically have four primary material categories to choose from:

1. PU Leather (Polyurethane)

This is the industry standard for premium corporate gifts. It mimics the look and feel of genuine leather but offers better color consistency and water resistance.

- Pros: Huge variety of textures (smooth, grain, lizard skin), cost-effective, vegan-friendly, excellent for embossing.

- Cons: Less durable than genuine leather over decades (though sufficient for the lifespan of a notebook).

- Best for: Executive gifts, conference handouts, employee onboarding kits.

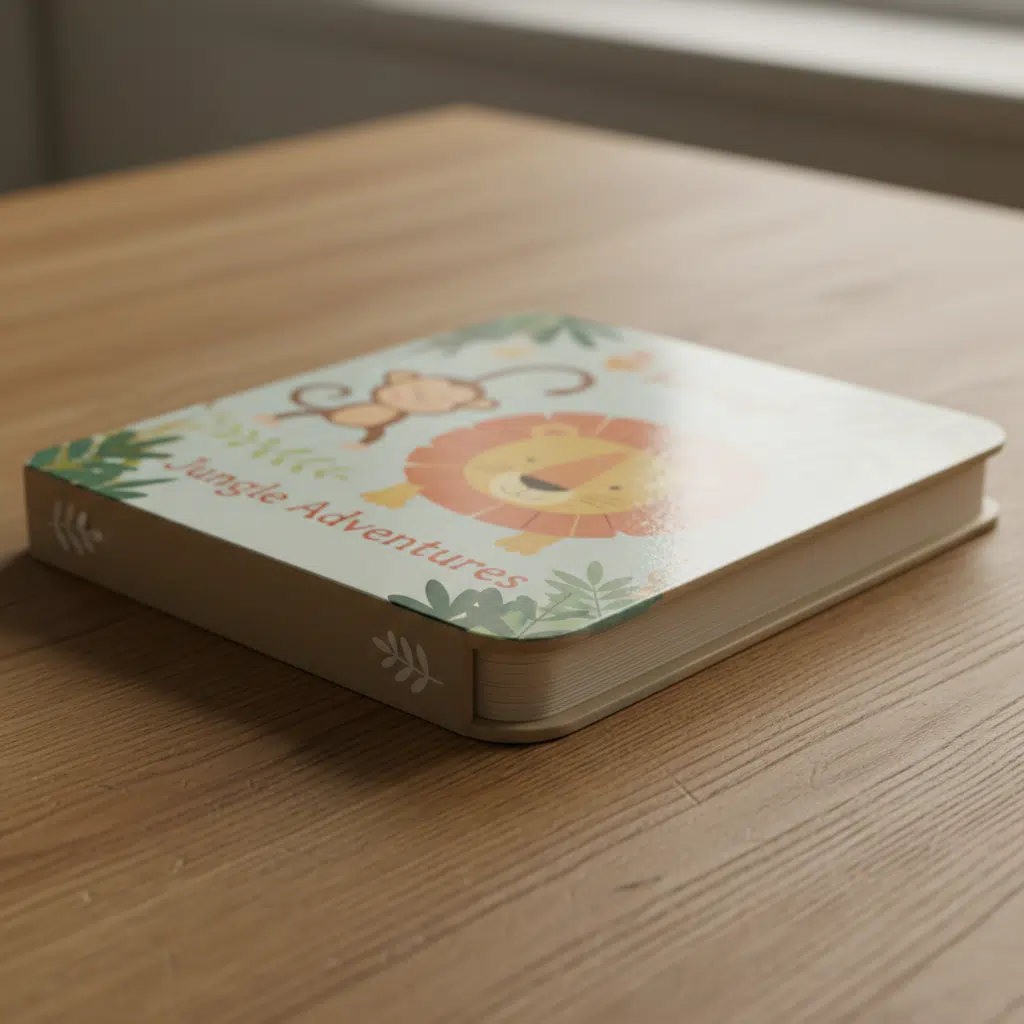

2. Hardcover (Paper wrapped over Greyboard)

A printed paper sheet is laminated and wrapped around a rigid greyboard core (typically 1.5mm to 3mm thick). This allows for full-color printing (CMYK) across the entire cover.

- Pros: Unlimited design flexibility (photos, gradients), rigid protection.

- Cons: Corners can wear down faster than PU leather.

- Best for: Retail products, educational notebooks, design-heavy branding.

3. Kraft Paper & Cardstock

A softer, flexible cover option often associated with eco-friendly branding.

- Pros: Lightweight, recyclable, lower cost.

- Cons: Less protection for inner pages; susceptible to bending.

- Best for: Event giveaways, eco-conscious campaigns, field notes.

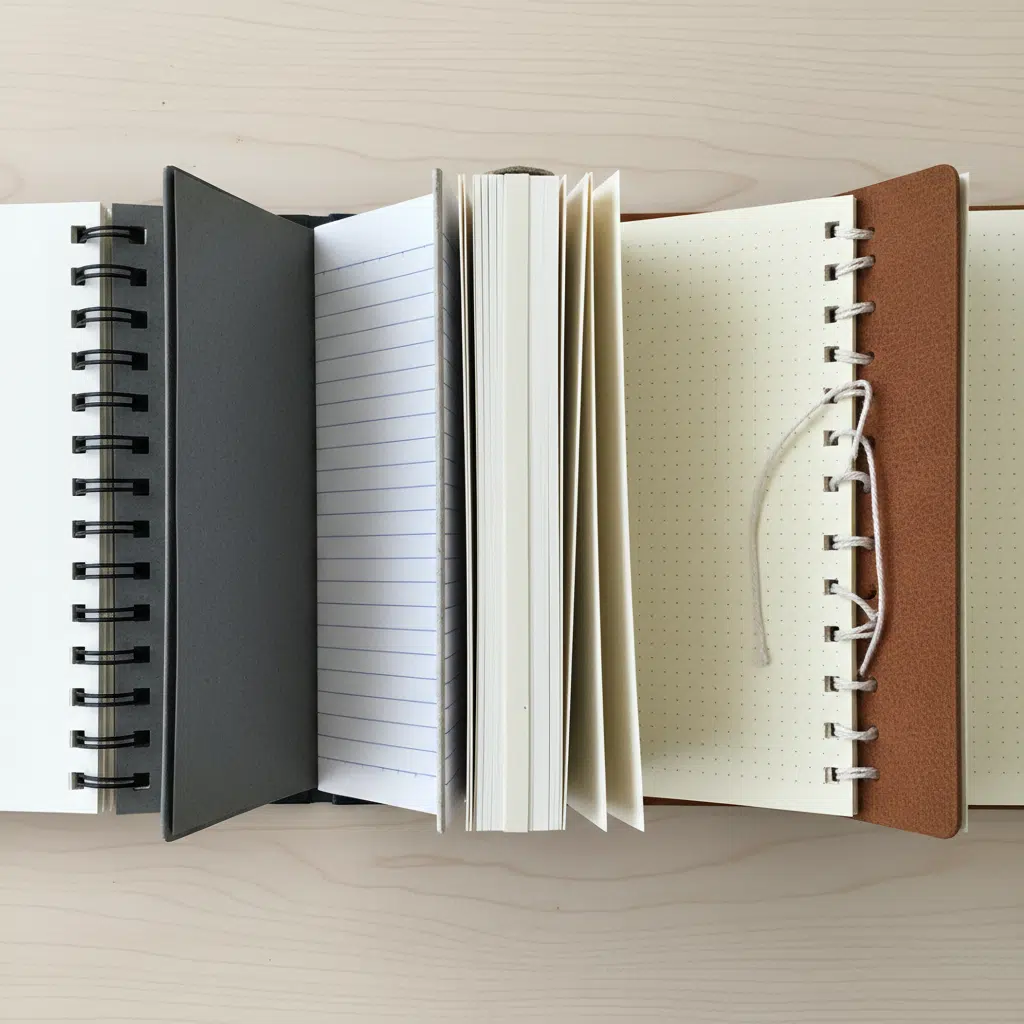

Binding Styles: Durability vs. Functionality

The binding method determines whether the notebook lies flat and how long it survives daily use. This is a critical specification in your manufacturing contract.

| Binding Type | Description | Lay-Flat Capability | Durability |

|---|---|---|---|

| Saddle Stitch | Folded sheets stapled at the spine. | Fair (if thin) | Medium (low page count only) |

| Perfect Bound | Pages glued to the spine (like a paperback book). | Poor (spine may crack) | Medium |

| Thread Sewn (Smyth Sewn) | Signatures are stitched together, then glued. | Excellent | High |

| Wire-O / Spiral | Metal coil through punched holes. | Excellent (360 degrees) | High |

For premium corporate notebooks, Thread Sewn binding is usually the preferred choice. It allows the book to open completely flat on a desk without breaking the spine, which is essential for user comfort.

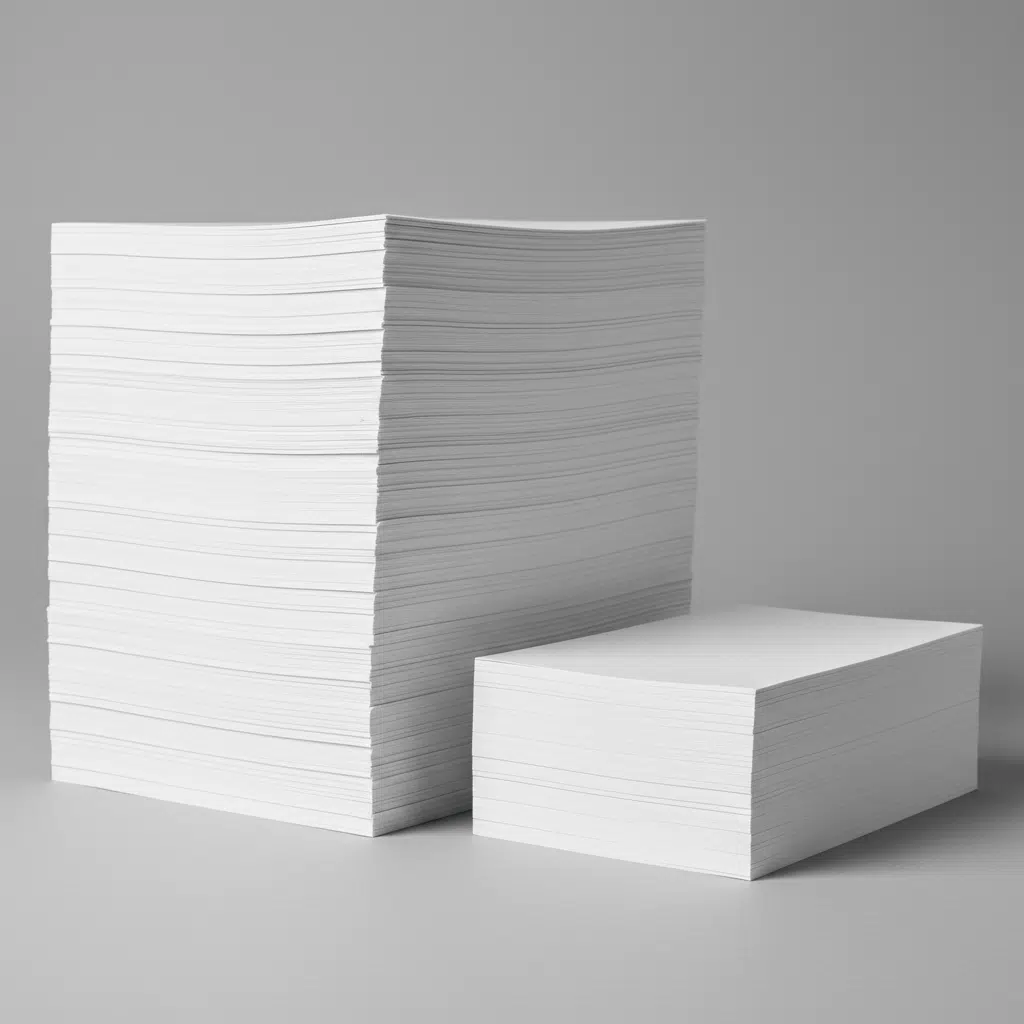

Inner Paper Specifications

Don’t overlook the paper quality. Using standard copier paper (usually 70gsm or 80gsm) may result in ink bleed-through if the user prefers fountain pens or heavy markers.

- Weight (GSM):

- 80gsm: Standard for mass-market notebooks. Good for ballpoint pens.

- 100gsm: Premium feel. Minimal show-through. Ideal for professional journals.

- 120gsm+: Art-quality. thick and heavy.

- Color:

- Ivory / Cream: Reduces eye strain and feels more luxurious.

- Bright White: Provides high contrast, better for technical sketching.

- Coating: Inner pages should generally be uncoated or wood-free to ensure ink dries quickly and doesn’t smudge.

Custom Branding Techniques

How you apply your logo affects the perceived value of the item. Industrial printing offers several methods beyond simple ink printing.

Debossing vs. Embossing

Debossing presses the logo into the cover material, creating an indentation. Embossing raises the logo above the surface. For PU leather notebooks, blind debossing (no foil, just texture) is a subtle, sophisticated choice favored by luxury brands.

Hot Foil Stamping

A heated die transfers metallic foil (gold, silver, copper, holographic) onto the cover. This creates a high-contrast, reflective finish that catches the eye. It works exceptionally well on dark covers (navy, black, charcoal).

Custom Flyleaves & Inserts

The flyleaf is the page glued to the inside of the cover. This is prime real estate for corporate messaging, company values, or contact information. Customizing the flyleaf with a full-color print adds a layer of polish to the product.

Buying Guide: Logistics and MOQ

Minimum Order Quantity (MOQ)

Custom manufacturing involves setup costs for printing plates, cutting dies, and foil stamps.

- 500–1,000 units: Typical starting point for fully custom notebooks (custom size, material, and inner pages).

- Below 500 units: Often restricted to “stock customization,” where a pre-made notebook is simply stamped with a logo. This limits your choice of materials and page layouts.

Artwork Preparation

To ensure production quality matches your design:

- Provide logos in vector format (AI, EPS, PDF) to prevent pixelation during die-making.

- If printing full-color covers, include at least 3mm of bleed area.

- Specify Pantone (PMS) colors if strict brand consistency is required.

Sampling

Before committing to a production run of 5,000 units, always request a pre-production sample. This allows you to test the paper with different pens, check the binding strength, and verify the color accuracy of the cover material.

Frequently Asked Questions

Can I customize the inner pages with my company logo on every sheet?

Yes. Custom watermarks or logos can be printed on every page. However, this requires custom offset printing for the inner block, which typically requires a higher MOQ (often 1,000+ units) compared to using standard lined or blank stock.

What is the difference between PU leather and PVC?

PU (Polyurethane) is generally softer, more flexible, and more environmentally friendly than PVC (Polyvinyl Chloride). PU mimics the breathability and feel of real leather better than PVC, making it the superior choice for high-end notebooks.

How long does production take?

For a fully custom order, allow 15–25 days for production after artwork approval, plus shipping time. Complex features like magnetic closures or pockets may add to this timeline.

Do you offer elastic bands and ribbon markers?

Yes, accessories are fully customizable. You can match the elastic band and ribbon marker color to your brand’s Pantone color, or choose a contrasting color for a bold look.

Request a Quote for Custom Notebooks

Ready to upgrade your corporate stationery? Whether you need 500 branded journals for an event or 10,000 units for retail distribution, we provide professional manufacturing solutions tailored to your specifications.

Contact us today to request a quote or get a sample kit.