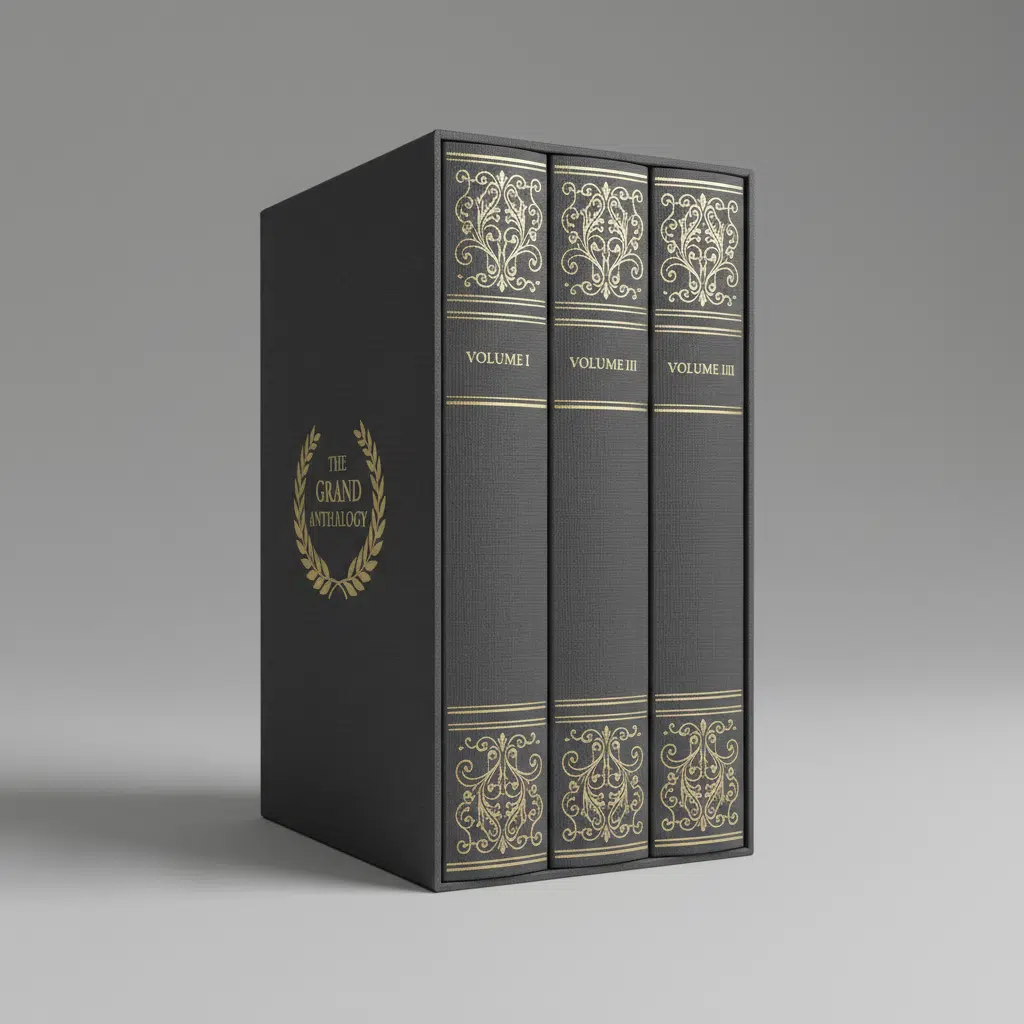

For publishers and brand owners, a multi-volume book set represents a significant investment in content and design. However, the perceived value of these collections is often determined before the reader even opens the first volume. The slipcase—the rigid protective enclosure that houses the books—serves as both a shield and a marketing canvas.

In the world of B2B printing and packaging, designing custom slipcases requires a balance of structural engineering and aesthetic finesse. Unlike standard folding cartons, rigid slipcases must withstand the weight of multiple hardcover books while maintaining a premium feel. This guide explores the manufacturing considerations for high-end book slipcases, focusing on material selection, structural integrity, and finishing options for collector’s editions.

The Structural Core: Greyboard Thickness and Rigidity

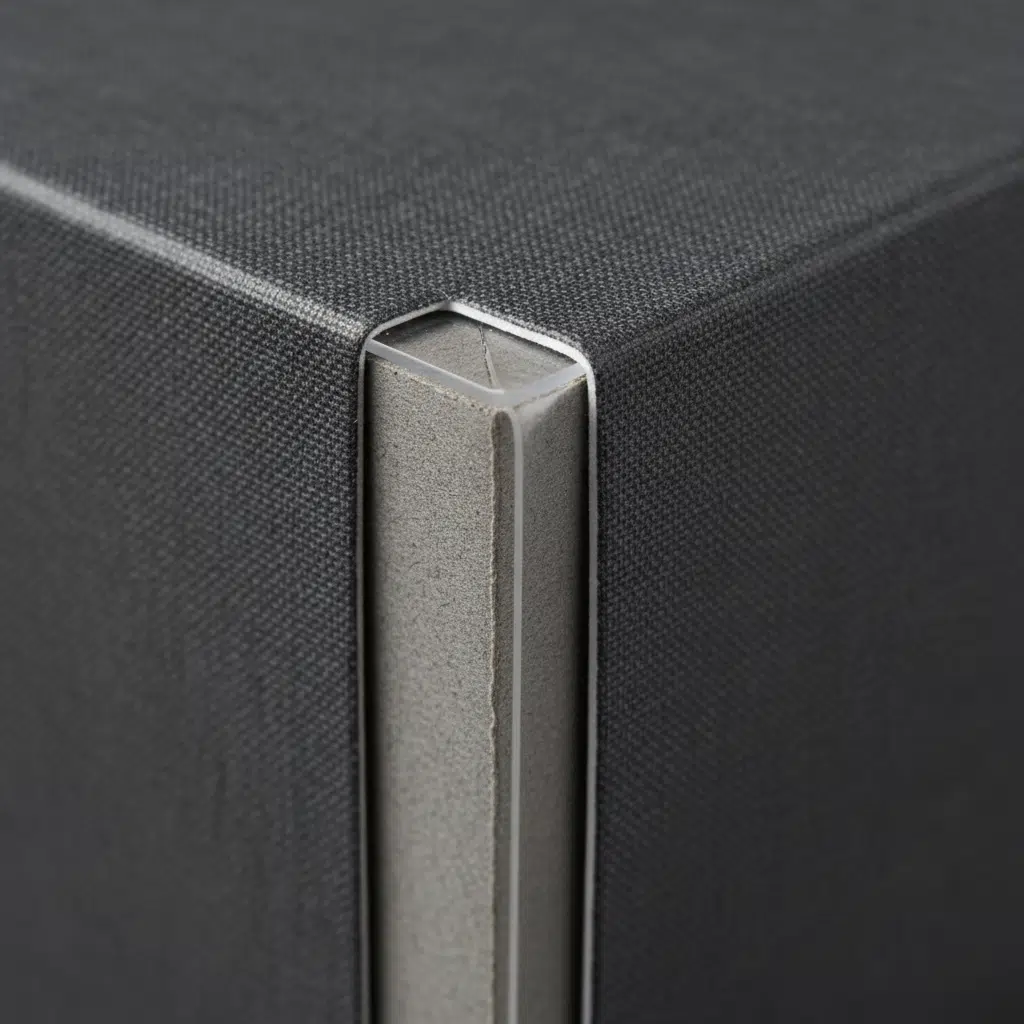

The foundation of any high-quality slipcase is the greyboard (also known as chipboard). This material provides the skeleton of the box. For multi-volume sets, standard packaging board is often insufficient. The structural integrity depends heavily on the thickness and density of the board selected.

Selecting the Right Caliper

Choosing the correct board thickness is a trade-off between durability and bulk. Common specifications include:

- 1.5mm to 2.0mm (approx. 1000gsm – 1200gsm): Suitable for single hardcover books or lightweight paperback sets. This offers a sturdy feel without excessive weight.

- 2.5mm to 3.0mm (approx. 1600gsm – 1800gsm): The industry standard for heavy, multi-volume encyclopedias, art books, or deluxe collector’s sets. This thickness prevents the walls from bowing under the weight of the books during shipping and shelving.

For sets exceeding 3kg, reinforced corners or double-wall construction may be recommended to prevent crushing impacts during logistics.

Wrapping Materials: The "Skin" of the Slipcase

Once the greyboard structure is formed, it is wrapped (laminated) with a cover material. This layer defines the visual and tactile experience of the product. Manufacturers typically offer three primary categories of wrapping paper.

1. Coated Art Paper (C1S)

Coated one-side art paper is the most versatile option for branding. It allows for high-resolution, full-color (CMYK) offset printing. This is ideal for slipcases that require photographic artwork, complex illustrations, or strict brand color matching. It is almost always finished with lamination (matte, gloss, or soft-touch) to protect the ink and prevent cracking at the fold lines.

2. Specialty and Textured Papers

For limited editions and luxury releases, specialty papers offer an immediate sense of prestige. Options include:

- Linen or Cloth-Textured Paper: Simulates the look and feel of fabric binding, offering a classic library aesthetic.

- Leatherette: A synthetic paper that mimics the grain of leather, popular for corporate gifts or historical reprints.

- Dyed Uncoated Stock: Paper that is dyed through the core (not just printed on top), ensuring that edges and scuffs do not reveal white fibers underneath.

3. Kraft Paper

For brands focusing on sustainability or a rustic aesthetic, unbleached Kraft paper provides a natural look. It is durable and pairs well with simple one-color black printing or foil stamping.

Critical Design Features for Functionality

A beautiful slipcase fails if the user cannot easily remove the books. Functional design features must be integrated into the die-line early in the process.

Fit and Tolerance

The "fit" is the most challenging aspect of slipcase manufacturing. If the case is too tight, a vacuum effect is created, making it impossible to remove the books without damaging them. If too loose, the books will rattle and potentially sustain corner damage.

Manufacturers typically aim for a tolerance gap of 1mm to 2mm on the top and spine sides. This allows for the natural expansion of paper in humid environments while keeping the books secure.

Extraction Methods

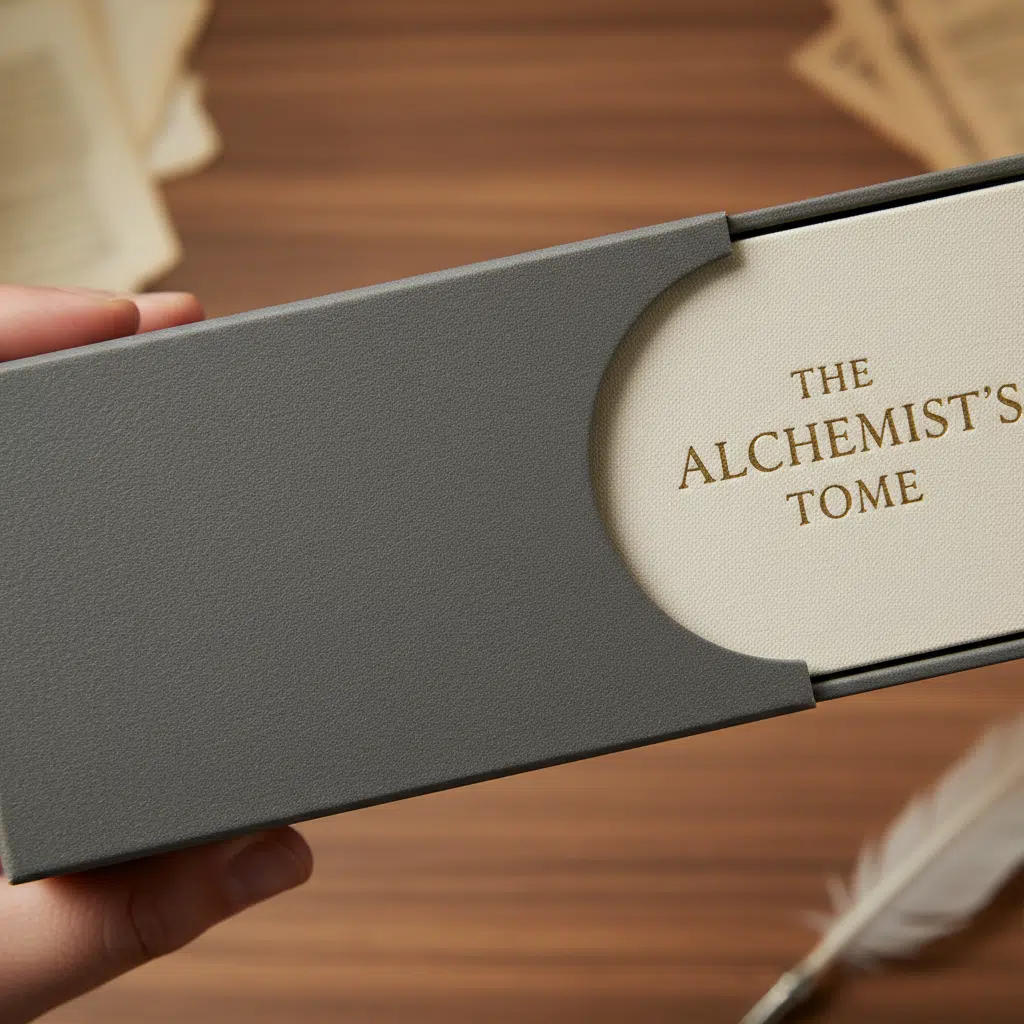

- Thumb Cuts (Finger Notches): A semi-circular cut-out on the open edges of the slipcase allows the user to grip the book spines. This is the standard solution for most sets.

- Ribbon Pulls: For a more elegant solution, a ribbon can be anchored to the inside back wall of the slipcase, laying under the books. Pulling the ribbon ejects the books gently. This is common in luxury packaging where preserving the spine condition is paramount.

Surface Finishes and Embellishments

To elevate a slipcase from a simple container to a collector’s item, post-press finishes are essential. These techniques are applied to the wrapping paper before it is glued to the board.

- Hot Foil Stamping: Metallic gold, silver, or holographic foils are stamped onto the spine and cover. This is highly effective on textured papers where ink printing might lack vibrancy.

- Spot UV: A high-gloss clear varnish applied over specific areas (like a title or logo) to create contrast against a matte background.

- Debossing/Embossing: Pressing a design into the board creates a 3D tactile effect. Blind debossing (without ink/foil) on leatherette paper creates a subtle, sophisticated look.

- Anti-Scratch Lamination: For matte black or dark-colored slipcases, standard lamination shows scuffs easily. Anti-scratch lamination is highly recommended to maintain a pristine appearance throughout the supply chain.

B2B Buying Guide: Manufacturing Considerations

When procuring custom slipcases, several factors influence cost, lead time, and quality.

Minimum Order Quantities (MOQ)

Due to the complex setup involved in rigid box manufacturing—including custom die-making, foil stamping plates, and manual assembly steps—MOQs are typically higher than digital printing products. Buyers should generally anticipate MOQs starting at 500 to 1,000 units to achieve a viable unit cost.

Prototyping is Mandatory

Never proceed to mass production without a physical white sample (structural dummy). You must physically insert the actual production copies of your books into the sample slipcase to verify the fit. Paper thickness in books can vary slightly between print runs; verifying the combined spine width of the set is crucial.

Artwork Preparation

Designers should request a custom template (dieline) from the manufacturer. Because the paper wraps around the thick board, significant bleed (usually 15-20mm) is required to ensure the board is fully covered on the inside lip.

FAQ: Custom Slipcase Production

What is the difference between a slipcase and a clamshell box?

A slipcase is open on one side (usually the spine side) and books slide in. A clamshell box (or presentation box) is a hinged box that opens like a book or a pizza box, enclosing the contents on all sides. Clamshells offer higher protection but are more expensive to manufacture.

Can you print inside the slipcase?

Yes. The interior is usually lined with standard white woodfree paper, but you can opt for a printed liner or a solid color liner to match the exterior branding.

How do I measure my book set for a slipcase?

Measure the total width of the spines when the books are stacked together (without squeezing them too tight), the height of the cover, and the depth (front to back). Provide these exact dimensions to the manufacturer, who will calculate the necessary internal allowance.

Are slipcases shipped flat or assembled?

Rigid slipcases are "set-up" boxes, meaning they are manufactured and shipped fully assembled. They cannot be folded flat. This increases shipping volume compared to folding cartons, so logistics costs should be factored into the total landed cost.

Ready to elevate your publication with custom rigid packaging? Request a quote or get a sample today to discuss your specifications.