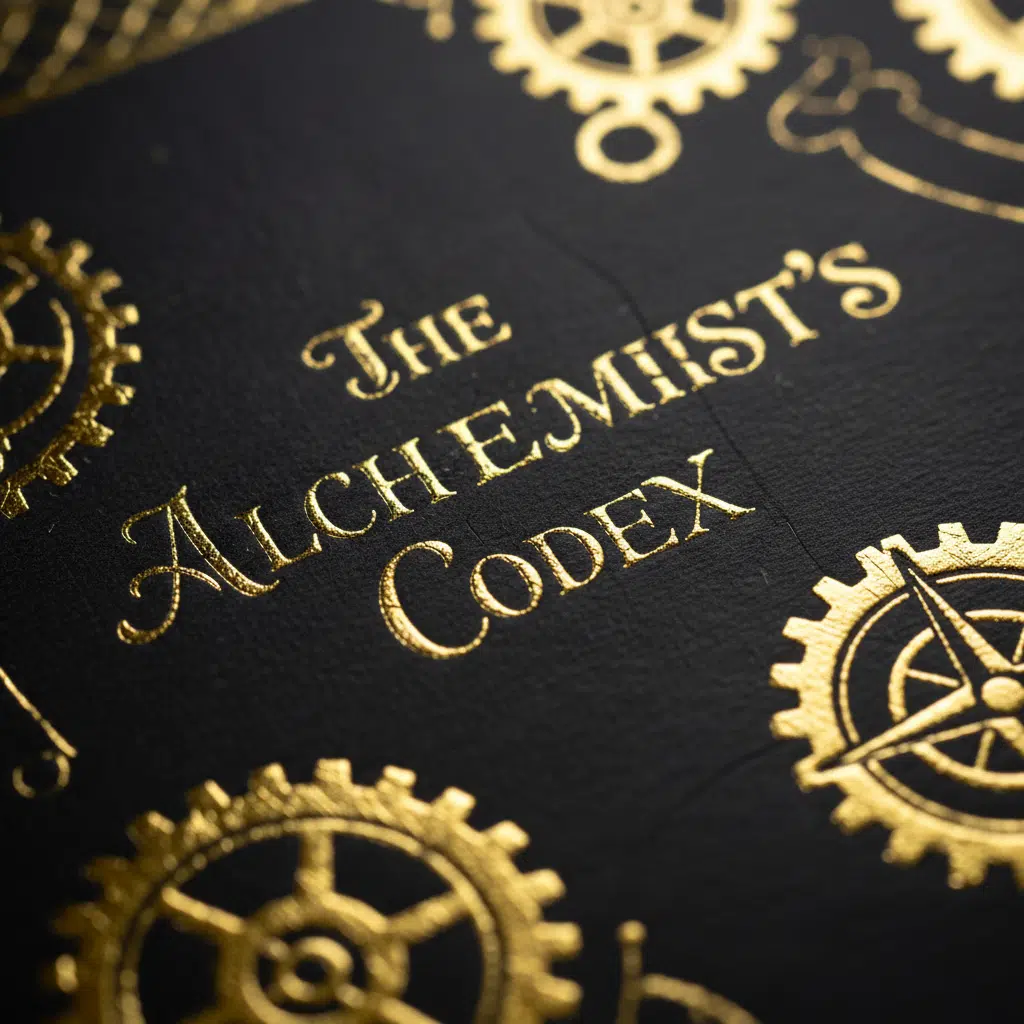

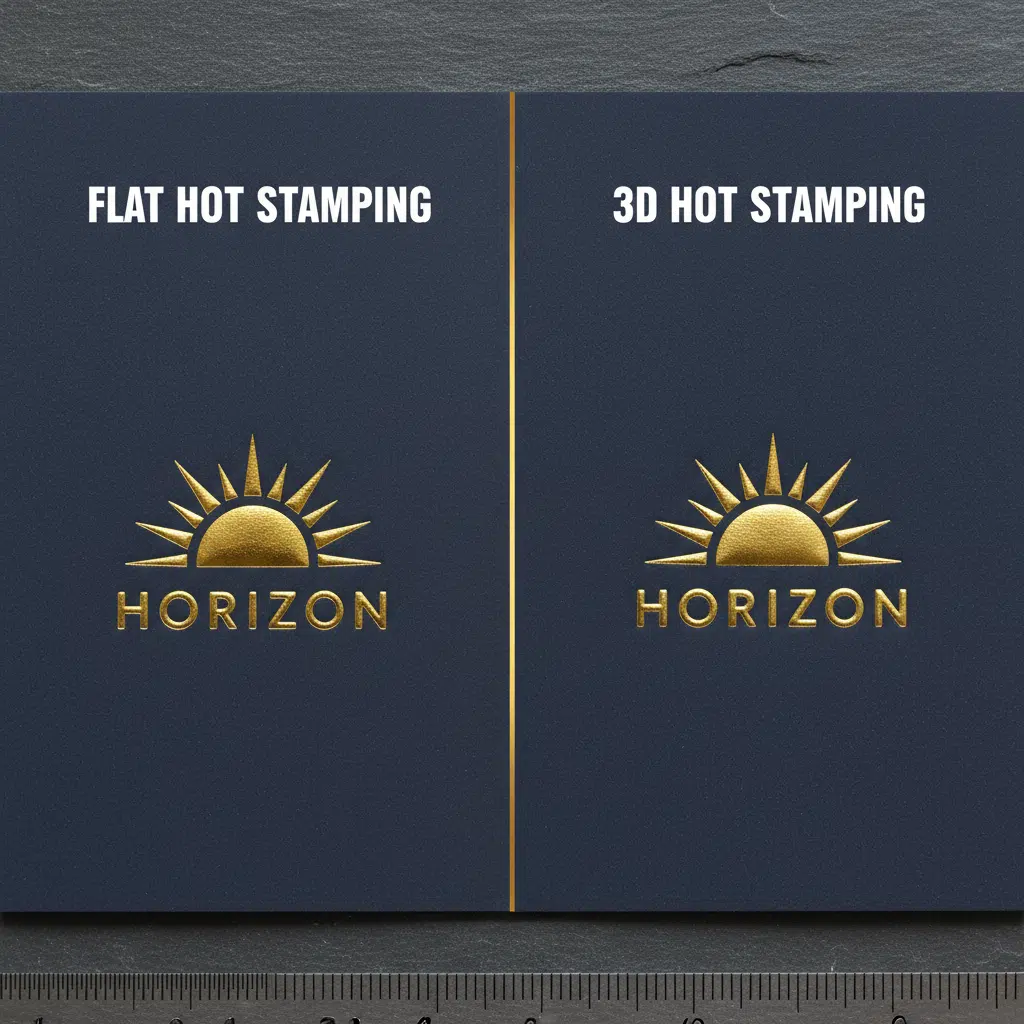

In the competitive world of high-end book publishing and packaging, shelf appeal is often determined by tactile finishes. Three-dimensional (3D) hot stamping—often referred to as combination stamping or foil embossing—is one of the most effective techniques for creating a premium, multi-sensory experience. Unlike standard flat hot stamping, which simply applies metallic foil to the surface, 3D hot stamping simultaneously applies foil and embosses the substrate, creating a raised, sculpted relief.

This process is technically demanding. It requires a precise balance of temperature, pressure, and speed to ensure the foil adheres correctly while the paper fibers are reshaped. For procurement officers and brand managers, understanding the mechanics of this process is essential for specifying the right materials and setting realistic quality expectations.

Understanding the Process: One Pass, Dual Effect

The core distinction of three-dimensional hot stamping is that it combines two finishing steps into a single machine pass. In traditional workflows, a printer might apply hot foil in one pass and then emboss the paper in a second pass. While this works, maintaining perfect registration (alignment) between the foil and the emboss is difficult.

3D hot stamping solves this by using a specialized die set—typically a sculpted brass female die and a matching male counter-die. The foil is fed between the die and the substrate. When the heated die strikes the paper against the counter-die, it transfers the foil and molds the paper fibers simultaneously. The result is a sharp, perfectly registered multi-level image that catches light from different angles.

To learn more about how this fits into broader production workflows, you can explore our detailed guide on <a href=”What is the three-dimensional hot stamping process for book printing?“>three-dimensional hot stamping processes.

The Three Pillars of Quality Control

Achieving a flawless 3D stamp is significantly harder than standard flat stamping. Operators must strictly control three variables: temperature, pressure, and speed. A deviation in any of these can lead to costly waste.

1. Temperature: The High-Heat Requirement

Temperature is perhaps the most critical variable. Standard flat hot stamping typically operates between 70°C and 90°C. However, 3D hot stamping requires significantly higher temperatures, often around 150°C.

Why the difference? The process must not only activate the adhesive on the foil but also soften the paper fibers enough to be permanently molded without cracking. If the temperature is too low, the foil’s adhesive layer may not melt completely, causing the foil to peel or look patchy (a defect known as “blistering” or “exposure of the bottom”).

Conversely, if the temperature exceeds the optimal range, several issues arise:

- Foil Fogging: The metallic finish loses its luster and becomes dull.

- Blurred Edges: The adhesive spreads beyond the image area, ruining fine details.

- Die Expansion: Metal dies expand with heat. Excessive heat can cause the die to expand beyond tolerance, leading to registration errors with the counter-die.

2. Pressure: Molding the Substrate

Pressure in 3D hot stamping serves two purposes: transferring the foil and physically reshaping the paper. This requires significantly higher tonnage than flat stamping. The pressure must be strong enough to compress the fibers and form a permanent relief, but controlled enough to avoid crushing the substrate or cutting through the paper.

The Risk of Imbalance:

- Too much pressure: Can cut the paper at the edges of the design or crush the grain of the surrounding material, ruining the texture of the book cover.

- Too little pressure: Results in a weak emboss (low relief) and poor foil adhesion.

3. Speed (Dwell Time)

Speed determines the “dwell time”—the duration the hot die is in contact with the foil and paper. This is a trade-off between production efficiency and quality.

- Fast Speed (Short Dwell): Increases output but reduces the time available for heat transfer. If the machine runs too fast, the temperature may drop, leading to weak adhesion.

- Slow Speed (Long Dwell): Ensures excellent adhesion and sharp embossing but risks overheating the substrate or slowing down the production line significantly.

Design and Material Specifications

When requesting a quote for 3D hot stamping, the choice of materials impacts the feasibility of the project.

Paper and Board Selection

Not all papers can withstand the stress of 3D stamping. Long-fiber papers and heavier cardstocks (typically 250gsm and above) are preferred because they stretch rather than tear. Coated papers generally provide a sharper foil release than uncoated stocks, though uncoated stocks offer a deeper tactile contrast.

Artwork Guidelines

To ensure the best results, designers should adhere to specific rules for 3D dies:

- Avoid hairline fonts: Serifs and thin lines may break or fill in during the stamping process.

- Spacing: Ensure adequate space between stamped elements to prevent the foil from bridging (connecting unwanted areas).

- Vector Files: Always supply artwork in vector format to ensure the die maker can create precise CNC-milled brass dies.

Buying Guide: Key Considerations

Before finalizing your order for book covers or packaging with 3D hot stamping, consider the following:

- Tooling Costs: 3D dies are CNC-milled from brass, making them significantly more expensive than the magnesium or copper dies used for flat stamping. This cost is usually a one-time setup fee.

- Lead Times: Allow extra time for die manufacturing (usually 3–5 days) in addition to the printing lead time.

- MOQ (Minimum Order Quantity): Due to the long setup times (makeready) required to align the male and female dies, this process is most cost-effective for runs of 500 units or more.

Frequently Asked Questions (FAQs)

Can 3D hot stamping be done on any paper?

No. Extremely thin papers (under 100gsm) will likely wrinkle or tear under the pressure. Heavily textured papers can also be challenging as the foil may not adhere to the valleys of the texture without excessive pressure.

What is the difference between embossing and 3D hot stamping?

Blind embossing creates a raised image without ink or foil. 3D hot stamping applies metallic foil and embosses the image simultaneously, resulting in a metallic, raised effect.

Why is the setup cost higher for this process?

The process requires a matched set of dies (male and female) which must be precisely aligned. The makeready process—adjusting the machine to apply even pressure across the entire image—is time-consuming and requires skilled operators.

Does 3D stamping work with holographic foils?

Yes, holographic foils can be used, but the alignment of the holographic pattern relative to the emboss must be carefully managed. Consult your printer early in the design phase.

Request a Consultation

3D hot stamping transforms ordinary book covers into collector’s items. However, the technical complexity requires an experienced manufacturing partner. If you are planning a project that requires high-precision <a href=”What is the three-dimensional hot stamping process for book printing?“>three-dimensional hot stamping, contact our technical team today.

Ready to elevate your print project?