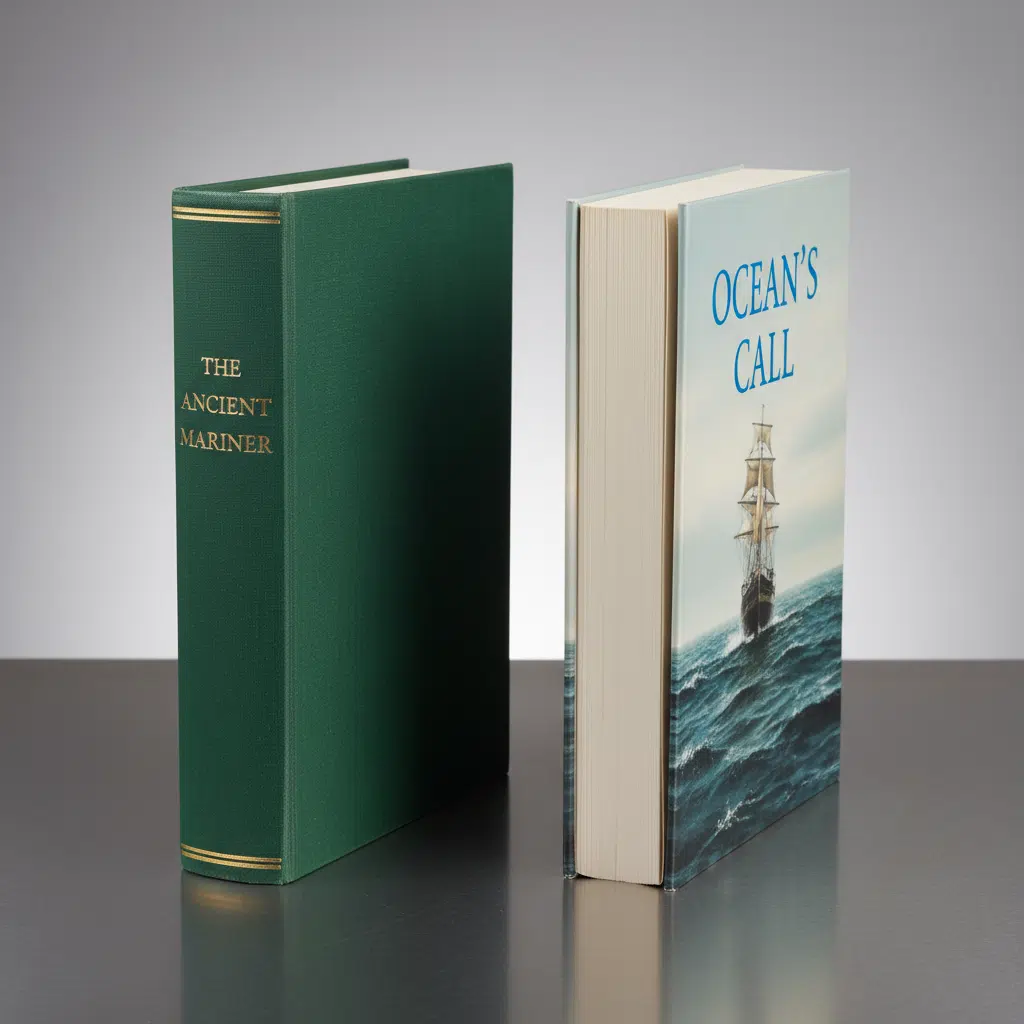

For commercial publishers, corporate procurement teams, and independent authors alike, the choice of binding style is a critical decision that impacts not just the aesthetics of the final product, but the entire economics of a print project. While hardcover (case) binding offers a traditional sense of prestige, paperback binding (often referred to as softcover or perfect binding) has evolved into the industry standard for balancing durability, design flexibility, and cost-efficiency.

In the competitive landscape of book manufacturing, understanding the technical and logistical benefits of paperback binding allows buyers to make informed decisions that optimize budget without compromising on quality. This guide explores the five strategic reasons to prioritize paperback binding for your next print run, along with technical insights into the manufacturing process.

1. Cost Efficiency: Beyond the Unit Price

The most immediate advantage of paperback binding is the reduction in manufacturing costs. However, for B2B buyers, the savings extend beyond the simple unit price.

- Material Reduction: Paperback binding eliminates the need for greyboard (the rigid board inside hardcover cases), cloth or paper wrapping, and endpapers. This reduction in raw materials significantly lowers the bill of materials (BOM).

- Streamlined Assembly: The production line for softcover books is more automated and requires fewer steps than hardcover binding. There is no “casing-in” process, which reduces machine setup times and labor costs.

- Scalability: The cost benefits of paperback binding scale aggressively with volume. For high-volume runs (e.g., 5,000+ units), the lower setup costs and faster cycle times result in a drastically lower cost-per-unit compared to case binding.

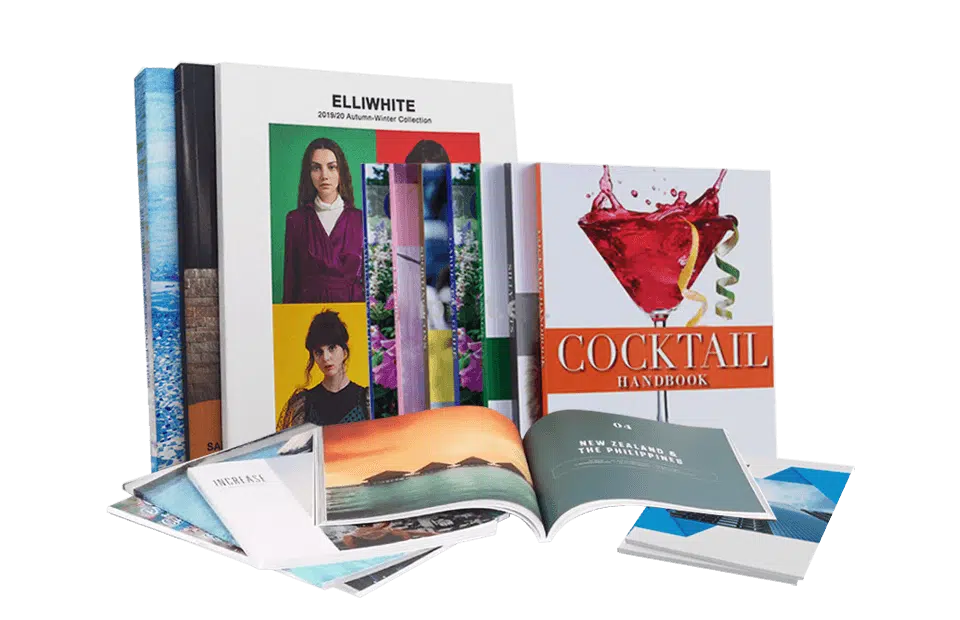

2. Design Flexibility and Shelf Appeal

Modern paperback binding is no longer synonymous with “cheap.” With advancements in cover stocks and finishing technologies, softcover books can achieve a premium look and feel that rivals hardcovers.

Advanced Finishing Options

To differentiate a product on the shelf, industrial printers offer a range of finishes that adhere perfectly to heavy cardstock covers:

- Lamination: Options include Gloss (high impact), Matte (elegant), and Soft-Touch (velvet feel).

- Spot UV & Foil Stamping: High-gloss varnish or metallic foils can be applied to specific areas (like the title or logo) to create contrast and texture.

- Embossing/Debossing: Adding tactile elements to the cover stock.

French Flaps

A popular enhancement for premium paperbacks is the addition of French flaps (gatefold covers). These extensions of the front and back cover fold inward, providing extra space for author bios or marketing copy, mimicking the feel of a hardcover dust jacket while maintaining the single-unit integrity of a paperback.

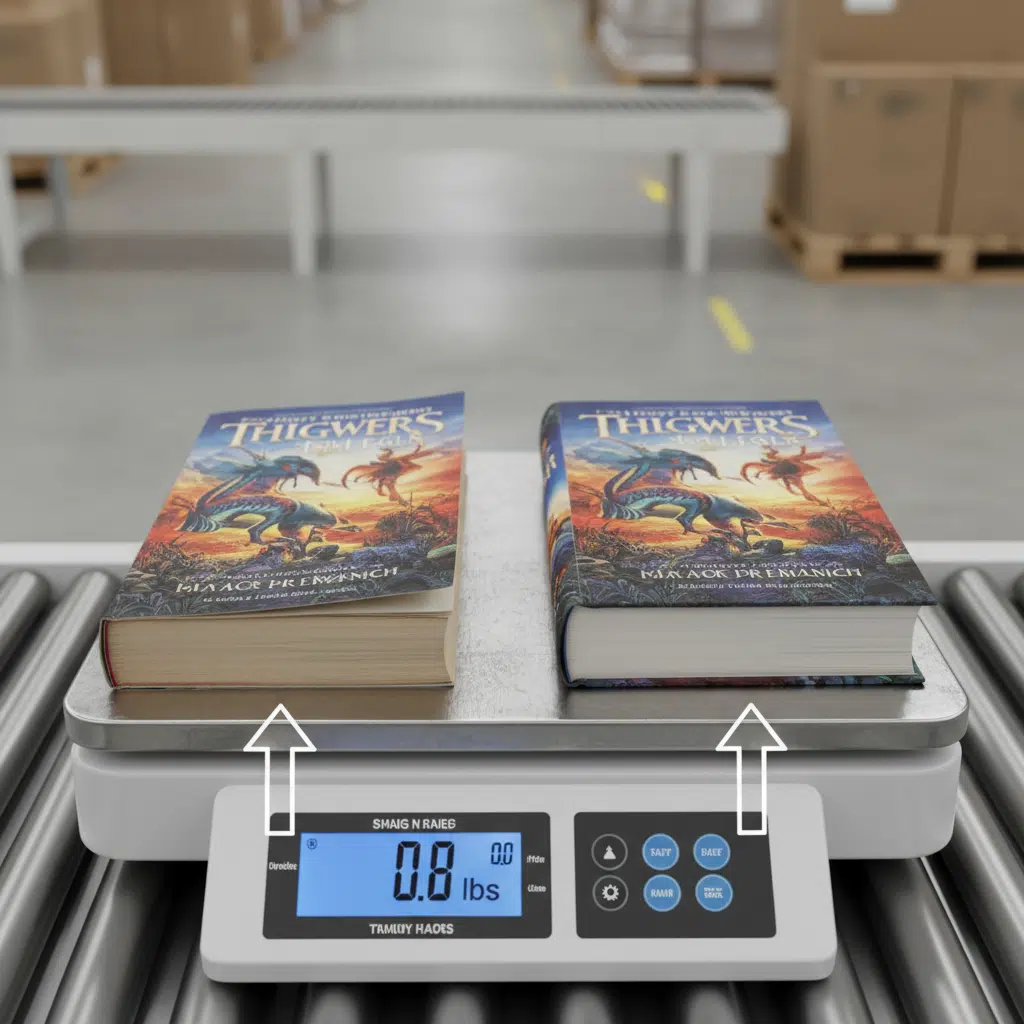

3. Logistics: The Weight Advantage

For international buyers and distributors, the weight of the final product is a crucial logistical factor. Paperback books are significantly lighter than their hardcover counterparts, which has a cascading effect on the supply chain.

- Shipping Costs: Hardcover books can weigh 30-50% more than paperbacks due to the heavy board and endpapers. When shipping pallets of books via air or sea freight, this weight difference translates into substantial savings.

- Storage Density: Softcover books are generally thinner (due to the lack of board overhang), allowing for more units to be packed per carton and per pallet. This maximizes warehouse efficiency and reduces storage fees.

- Portability for End-Users: For trade books, manuals, and educational materials, the reduced weight improves the user experience, particularly for items intended to be carried daily.

4. Sustainability and Eco-Friendliness

As corporate sustainability goals become stricter, the environmental footprint of print projects is under scrutiny. Paperback binding offers a more eco-friendly profile compared to traditional case binding.

- Monocaterial Potential: Paperback books are primarily paper and glue. Unlike hardcovers, which may use cloth, board, and non-paper covering materials, paperbacks are easier to recycle in standard paper streams (provided the glue is removed during the pulping process).

- Reduced Waste: The simplified manufacturing process generates less makeready waste.

- Recycled Stocks: It is standard practice to use recycled or FSC-certified coated/uncoated stocks for both the interior pages and the cover, allowing brands to meet environmental compliance standards easily.

5. Accelerated Speed to Market

In industries where time-to-market is critical—such as topical non-fiction, annual reports, or seasonal catalogs—paperback binding offers superior turnaround times.

Hardcover production requires significant drying and curing time for the adhesives used in case-making and casing-in. Additionally, the covers often need to be produced separately from the text blocks and then married together. In contrast, perfect binding lines can often collate, bind, and trim books in a continuous inline process. This efficiency can shave days or even weeks off production schedules, allowing publishers to react faster to market demands.

Technical Insight: The Perfect Binding Process

To ensure durability, it is important to understand the technology behind “paperback binding,” technically known as Perfect Binding.

The Process:

- Gathering: Folded signatures (groups of pages) are gathered together to form the book block.

- Spine Preparation: The spine edge of the block is milled (ground off) to expose the paper fibers. Notching may be added to increase surface area.

- Gluing: Adhesive is applied to the spine. There are two main types of glue used in industrial binding:

- EVA (Ethylene Vinyl Acetate): Traditional hot melt glue. Cost-effective and fast-curing. Best for standard papers and short-term use.

- PUR (Polyurethane Reactive): A stronger, more flexible adhesive. It bonds to coated papers and heavy ink coverage much better than EVA. It is highly resistant to temperature extremes and allows the book to lay flatter without cracking the spine.

- Cover Application: The cover is wrapped around the glued spine and clamped tight.

- Trimming: The book is trimmed on three sides (head, foot, and face) to create clean, flush edges.

Buying Guide: Specifying Your Order

When requesting a quote for paperback binding, providing precise specifications ensures accurate pricing and quality control. Consider the following parameters:

- Cover Stock: Typically 250gsm to 350gsm C1S (Coated One Side) art board. Heavier stocks feel more premium but may require scoring to prevent cracking.

- Binding Adhesive: Specify PUR binding if you are using coated paper (gloss/matte art paper) for the interior pages, or if the book will be subject to heavy usage.

- Spine Width: This must be calculated precisely based on the paper bulk (thickness) and page count. Your printer should provide a template.

- Grain Direction: Ensure the printer aligns the paper grain parallel to the spine. Cross-grain binding results in pages that resist turning and a book that snaps shut.

Frequently Asked Questions

Is paperback binding durable enough for textbooks?

Yes, provided PUR adhesive is used. PUR offers superior pull-test strength and flexibility, preventing pages from falling out even with repeated opening and closing. For extremely heavy use, however, section-sewn softcover (where signatures are sewn before gluing) is the most durable option.

What is the minimum page count for perfect binding?

Generally, a spine width of at least 3mm (approx. 32-40 pages depending on paper thickness) is required for the glue to hold effectively. For thinner publications, saddle stitching (stapling) is recommended.

Can I print on the inside of the cover?

Yes. This creates a “double-sided” cover effect. It is a cost-effective way to add value, often used for maps, charts, or additional artwork.

Conclusion

Paperback binding offers a compelling combination of economy, speed, and versatility. By selecting the right materials and adhesives (specifically PUR), businesses can produce professional-grade books that withstand the rigors of the supply chain while maximizing ROI. Whether for mass-market fiction, corporate manuals, or product catalogs, softcover binding remains the smart choice for scalable print projects.

Ready to start your next book project? Request a quote today to discuss your specifications and receive a custom sample kit.