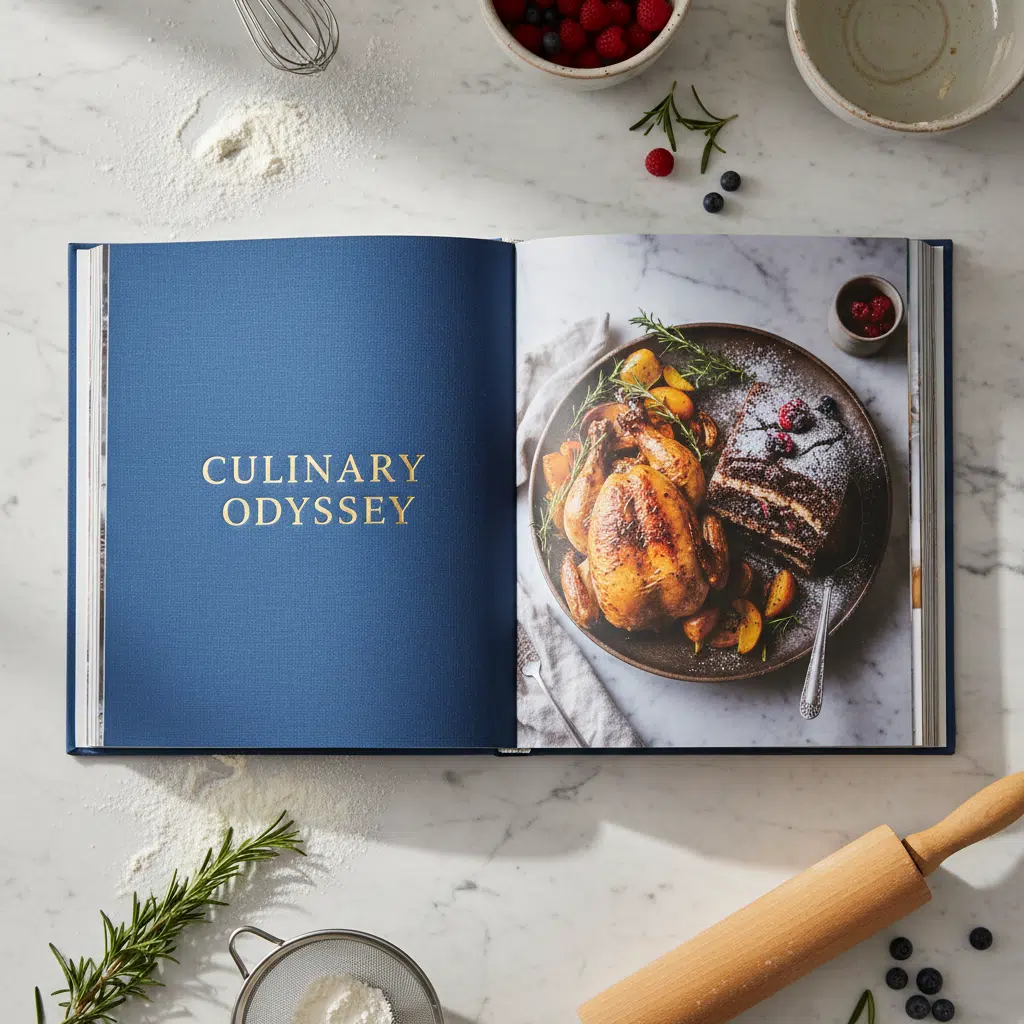

Balancing Visual Appeal with Kitchen Durability

For culinary publishers and brand owners, a cookbook is a dual-purpose product. It serves as an art book, showcasing high-resolution food photography that requires impeccable color reproduction. Simultaneously, it is a utility tool used in high-heat, high-moisture environments where oil splatters and flour dust are common.

Selecting the right specifications for cookbook printing services requires a technical understanding of materials. A beautiful book that falls apart after two months of use damages the publisher’s reputation. Conversely, a durable book with poor color management fails to sell the recipes. This guide outlines the critical decisions regarding paper stocks, protective coatings, and binding techniques specifically for professional cookbook manufacturing.

Selecting the Right Paper Stock

The choice of paper impacts opacity, texture, and how the ink sits on the surface (ink holdout). For cookbooks, the paper must support vibrant imagery while offering enough tensile strength to withstand page-turning.

Coated vs. Uncoated Stocks

- Coated Art Paper (Gloss or Matte): This is the industry standard for full-color cookbooks. The clay coating prevents ink from absorbing deep into the fibers, resulting in sharper images and a wider color gamut.

- Gloss Art: Maximizes color vibrancy and contrast. Ideal for modern, pop-style cookbooks.

- Matte Art: Reduces glare under kitchen lights while maintaining high print quality. Often preferred for a sophisticated, high-end feel.

- Uncoated (Woodfree/Offset): Uncoated paper offers a rustic, organic texture popular in artisan baking or farm-to-table titles. However, uncoated paper absorbs more ink, resulting in softer images (dot gain). It is also highly susceptible to staining and moisture absorption.

Recommended Paper Weights

Cookbooks generally require heavier stock than standard fiction books to prevent “show-through” (seeing images from the reverse side) and to provide a tactile sense of quality.

- Standard Interior: 128gsm to 157gsm (approx. 86lb to 105lb text). This range offers good opacity without making high-page-count books excessively heavy.

- Premium Interior: 157gsm to 200gsm. Used for coffee-table style cookbooks where luxury is the priority over portability.

Oil Resistance and Protective Coatings

A cookbook’s cover faces the harshest abuse. Standard varnish is often insufficient for a working kitchen environment. Publishers should consider specific laminations to ensure longevity.

Cover Finishes

- Thermal Lamination (PP/PET): This is mandatory for most cookbook covers (hardcover or softcover). A thin layer of plastic film is bonded to the paper. It makes the cover wipeable, water-resistant, and tear-resistant. Options include Gloss, Matte, and Soft-touch (Velvet) lamination.

- Spot UV: Often used in conjunction with matte lamination to highlight the title or specific food elements with a high-gloss finish.

Interior Protection

While laminating every interior page is cost-prohibitive for most projects, an aqueous varnish or press varnish should be applied to coated papers. This seals the ink, prevents smudging (set-off) during binding, and offers mild resistance to fingerprints.

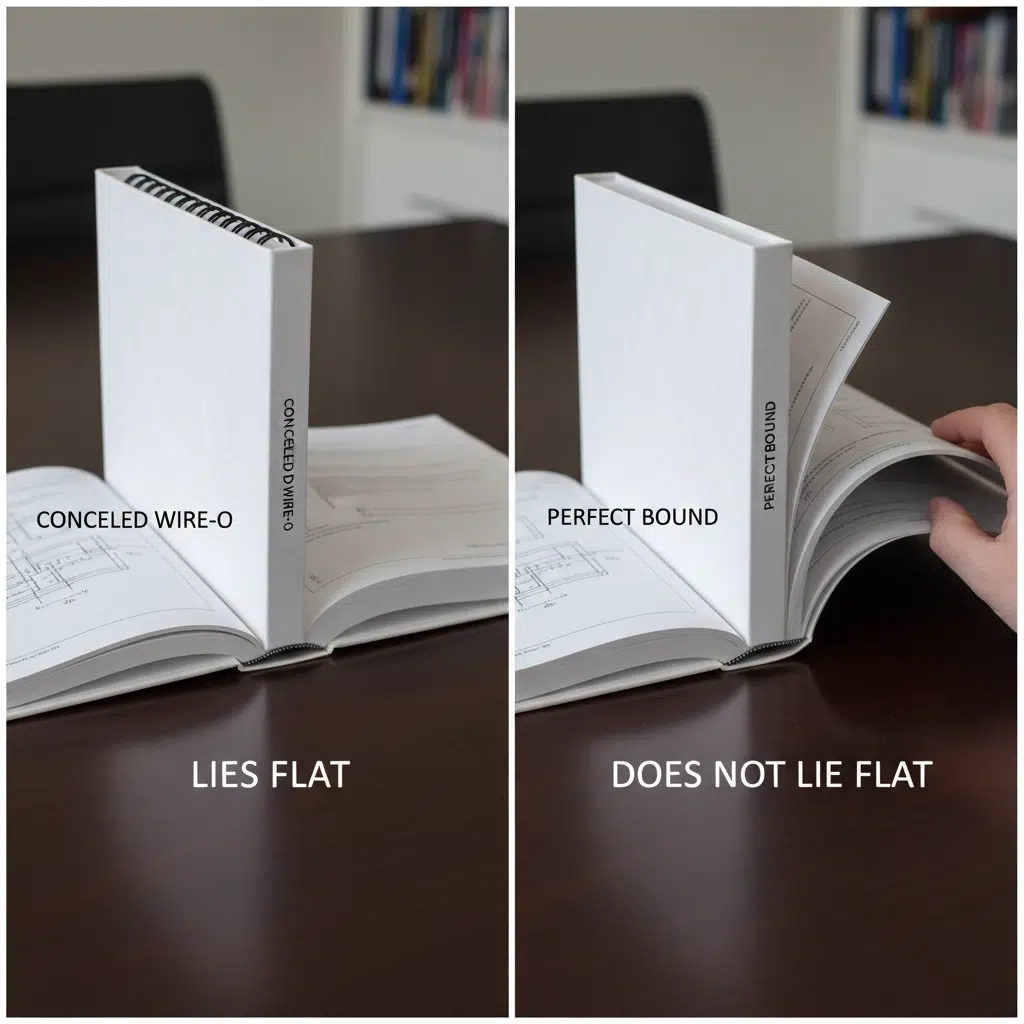

Binding Styles: Lay-Flat is Non-Negotiable

The most frequent complaint from home cooks is a book that snaps shut while they are chopping ingredients. Professional recipe book manufacturing must prioritize lay-flat capabilities.

1. Smyth Sewing (Section Sewn)

For hardcover (case bound) cookbooks, Smyth sewing is the gold standard. Signatures (groups of folded pages) are stitched together with thread before being glued into the spine.

Pros: Extreme durability; lays completely flat when opened; signatures cannot fall out.

Cons: Higher manufacturing cost and slightly longer lead time compared to adhesive binding.

2. Wire-O and Spiral Binding

Wire-O (double-loop wire) is highly functional for instructional manuals and fast-paced kitchen environments. It allows the book to open 360 degrees or lie perfectly flat without tension.

- Exposed Wire-O: The wire is visible on the spine. Practical but less shelf-friendly for retail bookstores.

- Concealed Wire-O (Canadian Binding): The wire is hidden inside a hard or soft cover, providing a printable spine for bookshelves while retaining the lay-flat utility.

3. PUR Perfect Binding

Standard perfect binding (EVA glue) is generally not recommended for cookbooks as it does not lay flat and pages can detach if the spine is cracked. However, PUR (Polyurethane Reactive) adhesive is significantly stronger and more flexible. It is a cost-effective option for softcover cookbooks, though it still lacks the superior lay-flat performance of sewing or wire.

Technical Considerations for Manufacturing

Color Management (CMYK)

Food photography relies on appetizing colors. Greens must look fresh, not muddy; reds (meats/fruits) must be vibrant.

Requirement: Ensure files are converted to the printer’s required CMYK profile (e.g., GRACoL 2013 or FOGRA39). Requesting a “wet proof” (hard copy proof on the actual paper stock) is advisable for checking color accuracy before the full production run.

Durability Add-ons

- Round Corners: Square corners on heavy hardcover books can easily become dog-eared or damaged during shipping and shelving. Rounding the corners adds durability and a unique aesthetic.

- Head and Tail Bands: Decorative fabric bands at the top and bottom of the spine hide the binding glue and add a finished look to hardcovers.

Buying Guide and FAQs

Common Questions

Q: What is the Minimum Order Quantity (MOQ) for custom cookbooks?

Most industrial offset printers set MOQs around 500 to 1,000 units. While digital printing can handle shorter runs, offset printing becomes significantly more cost-effective per unit as volumes increase (e.g., 2,000+ copies).

Q: Can I use different paper for different sections?

Yes. Some publishers use glossy coated paper for photo inserts and uncoated paper for text-heavy recipe instructions. This is called a “mixed stock” book. It requires careful planning of the signatures (page groupings) during the prepress phase.

Q: How do I ensure the cover is truly oil-resistant?

Specify “Thermal Lamination” (Polypropylene or Polyester) rather than just a varnish. Lamination creates a physical plastic barrier that oil cannot penetrate.

Requesting a Quote

When contacting a printer, provide the following details for an accurate estimate:

- Size: (e.g., 8.5″ x 11″ or A4)

- Page Count: Total pages (must usually be a multiple of 4, 8, or 16 for offset).

- Material: Cover stock and Interior stock (weight and coating).

- Binding: e.g., Hardcover Smyth Sewn or Softcover Wire-O.

- Finishing: Lamination, foil stamping, debossing.

- Quantity: e.g., 1,000, 3,000, 5,000.

For publishers looking to produce high-quality, durable cookbooks that withstand the rigors of the kitchen, selecting the right manufacturing partner is essential. Ensure your printer understands the specific demands of culinary publishing.