In B2B printing, the physical presentation of your document often speaks as loudly as the content itself. Whether you are producing a corporate history, a high-end product catalog, or an educational textbook, the choice of binding impacts durability, budget, and brand perception. While Hardcover Bookbinding Pros and Cons hardcover bookbinding pros and cons are often debated, the decision ultimately rests on the specific lifecycle requirements of your project.

This guide breaks down the technical and commercial considerations of case binding (hardcover) for purchasing managers and print buyers, moving beyond aesthetics to analyze ROI, production logistics, and longevity.

Understanding the Mechanics: What is Case Binding?

Hardcover binding, technically known as case binding, is a multi-step process where the internal pages (the book block) are attached to a rigid cover (the case). Unlike perfect binding, where the cover is merely glued to the spine, case binding involves:

- Signatures: Pages are printed in groups (usually 16 or 32) and folded.

- Sewing: These signatures are typically Smyth sewn or side-sewn for maximum strength.

- Endpapers: Heavyweight paper glues the book block to the inside of the hardcover case.

- The Case: Typically constructed from greyboard (2mm to 3mm thick) wrapped in printed paper, cloth, or leatherette.

The Pros: Why Invest in Hardcover?

1. Superior Durability and Longevity

The primary advantage of hardcover binding is structural integrity. The rigid boards protect the pages from bending, moisture, and corner damage. For B2B applications like technical manuals or reference guides that undergo frequent handling, this extends the replacement cycle significantly. A well-bound hardcover book can last decades, whereas a softcover manual may dog-ear and degrade within months of heavy industrial use.

2. Premium Brand Perception

Hardcovers command authority. In a stack of proposals or catalogs, the hardcover spine stands out physically and visually. This format allows for premium finishing options that are difficult to execute on softcovers, such as:

- Debossing and Embossing: Creating tactile depth on the board.

- Foil Stamping: Applying metallic foils directly to cloth or leatherette materials.

- Spot UV and Lamination: enhancing the visual appeal of printed covers.

3. Spine Rigidity and Shelf Presence

A hardcover book is self-supporting. It stands upright on a shelf, ensuring the spine title is always visible. For retail environments or corporate libraries, this visibility is a passive marketing tool that keeps your brand top-of-mind.

The Cons: Factors to Mitigate

1. Higher Unit Cost

Hardcover production is more material-intensive and labor-intensive. You should anticipate a unit cost that is 30% to 60% higher than a comparable perfect-bound softcover. This cost includes the greyboard, endpapers, and the additional “casing-in” production step.

2. Increased Weight and Logistics

The rigid boards add significant weight. For a standard 200-page A4 book, the hardcover version can weigh 20–30% more than its softcover counterpart. This impacts:

- Shipping Costs: Higher freight charges for bulk distribution.

- Storage: Heavier boxes require sturdy palletization.

- Portability: Less convenient for end-users who travel (e.g., field sales reps).

3. Longer Production Lead Times

Due to the complexity of case making and the drying time required for adhesives, production schedules are longer. While a softcover run might be completed in 7–10 days, a hardcover run often requires 15–20 business days depending on volume and finishing specs.

Comparison: Hardcover vs. Softcover ROI

| Feature | Hardcover (Case Bound) | Softcover (Perfect Bound) | Best Application |

|---|---|---|---|

| Durability | High (Years/Decades) | Medium (Months/Years) | Reference manuals, Yearbooks |

| Cost Index | $$$ | $ | Budget-sensitive handouts |

| Lay-Flat Ability | Excellent (if Smyth Sewn) | Poor (unless Otabind used) | Cookbooks, Art books |

| Turnaround | 3–5 Weeks | 1–2 Weeks | Urgent event collateral |

Production Workflow: What to Expect

Understanding the workflow helps in planning your project timeline. Here is the typical process at our ISO 9001 certified facility:

- Printing & Folding (Days 1–5): Text blocks are printed on offset presses and folded into signatures.

- Gathering & Sewing (Days 6–10): Signatures are collated and Smyth sewn for durability.

- Case Making (Days 6–10): Concurrent with sewing, the cover material is glued to the greyboard to create the “case.”

- Casing-In (Days 11–14): The book block is glued into the case using endpapers.

- Pressing & Curing (Days 15+): Books are pressed to ensure the glue sets flat and prevents warping.

Data Point: Our facility maintains a daily capacity of 15,000 hardcover units, ensuring we can handle high-volume seasonal demands without bottlenecks.

Strategic Use Cases

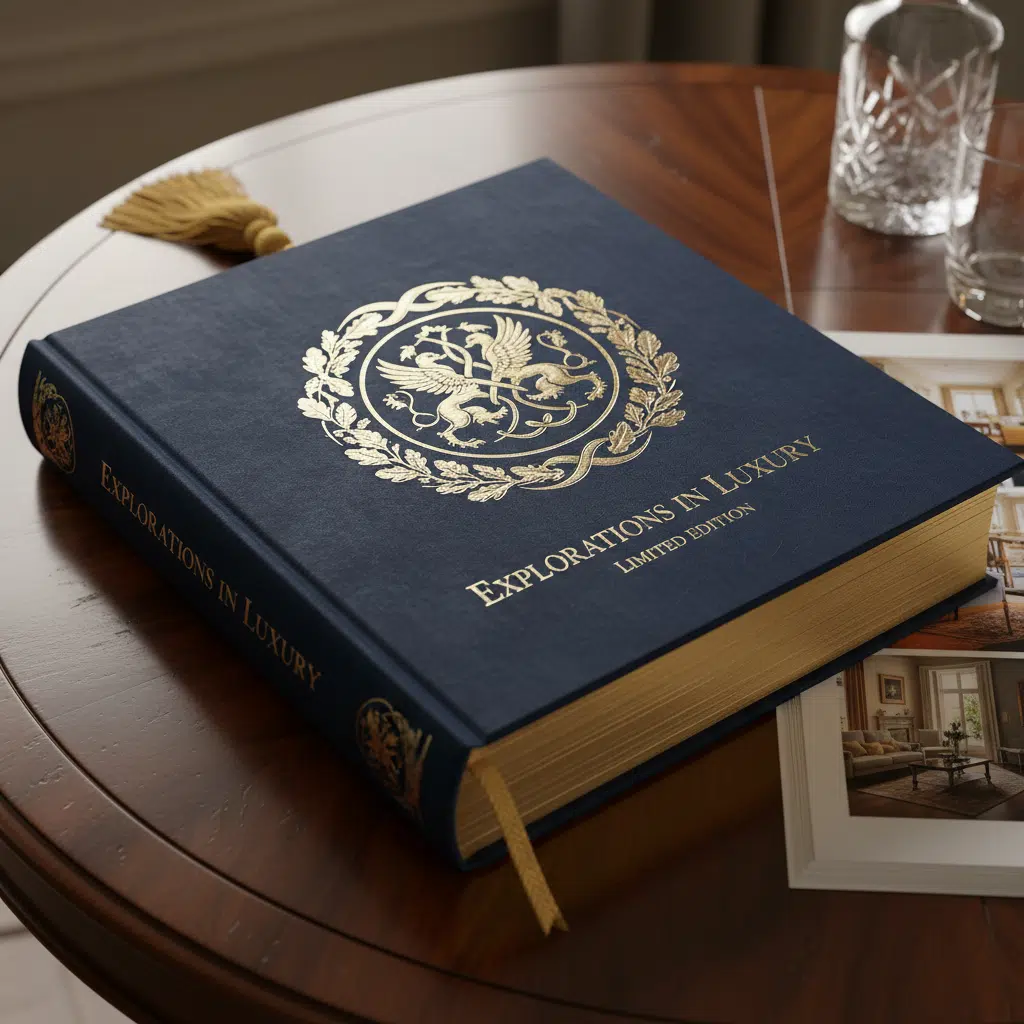

Sample Client: Luxury Furniture Manufacturer

A B2B furniture client switched from softcover to hardcover for their annual “Lookbook.” Although the unit cost increased by 40%, the catalog was designed to sit on the desks of interior designers for a full year. The switch reduced the need for mid-year reprints (as the softcovers were falling apart), resulting in a net annual saving of 15% and a higher conversion rate due to the premium presentation.

Downloadable Asset

Planning a project? Download our Hardcover Specification Checklist (PDF) to ensure you have all the details ready for your quote request, including spine width calculations and board thickness options.

Frequently Asked Questions

What is the Minimum Order Quantity (MOQ) for hardcover books?

Due to the setup time for case-making machines, the typical MOQ for cost-effective pricing is 500 to 1,000 units. Short-run digital hardcover is possible but carries a higher unit price.

Can hardcover books lay flat when opened?

Yes, if the book block is Smyth sewn. This allows the pages to open freely without cracking the spine, making it ideal for art books or technical manuals that need to stay open on a desk.

What is the difference between printed paper case (PPC) and cloth binding?

PPC involves printing graphics onto paper which is then laminated and wrapped around the board. Cloth binding uses a fabric material wrapped around the board, usually finished with foil stamping for the text. PPC allows for full-color photos, while cloth offers a classic, tactile feel.

How does page count affect the spine width?

The spine width is calculated based on the paper caliper (thickness) multiplied by the page count, plus the thickness of the boards. We provide a custom template for every project to ensure your spine artwork fits perfectly.

Are there eco-friendly hardcover options?

Yes. We offer FSC-certified greyboards and papers, as well as soy-based inks. While hardcovers use more material, their longevity often results in a lower environmental footprint over time compared to disposable softcovers.

Conclusion

Hardcover bookbinding offers a blend of durability and prestige that softcover options cannot match. While the initial investment and shipping weights are higher, the long-term value for brand assets, reference materials, and premium catalogs is undeniable. By weighing the pros and cons against your distribution strategy, you can select the binding method that delivers the best ROI.

Ready to elevate your next print project? Request a quote or get a sample of our premium hardcover finishes today.

About the Author: Mark Stevens is a Senior Production Specialist with over 15 years of experience in industrial bookbinding and offset printing. He specializes in helping B2B buyers navigate complex print specifications for maximum efficiency.