In the world of industrial offset printing, the transition from a digital design file to a physical product is the most critical juncture in the manufacturing process. For procurement managers and brand owners, approving a mass production run represents a significant financial commitment. A single error—whether a shifted color hue, a typo, or an incorrect fold—can render thousands of units unusable.

This is where the proofing stage becomes vital. While digital PDF proofs are standard for checking layout and content, they have limitations regarding color accuracy and material behavior. To truly mitigate risk, especially for high-stakes packaging or publishing projects, hard proof printing is the gold standard for verification.

This guide explains the technical differences between digital and hard proofs, specifically focusing on wet proofs and contract proofs, and helps you decide when the investment in a physical sample is necessary for your production workflow.

Digital Proofs vs. Hard Proofs: Understanding the Difference

Before authorizing a full production run, manufacturers provide a proof to simulate the final result. Understanding the limitations of each type is essential for quality assurance.

1. Digital Proofs (Soft Proofs)

A digital proof is typically a high-resolution PDF sent via email. It is the fastest and most cost-effective way to review a job.

- Best for: Verifying text, pagination, bleed margins, and general layout.

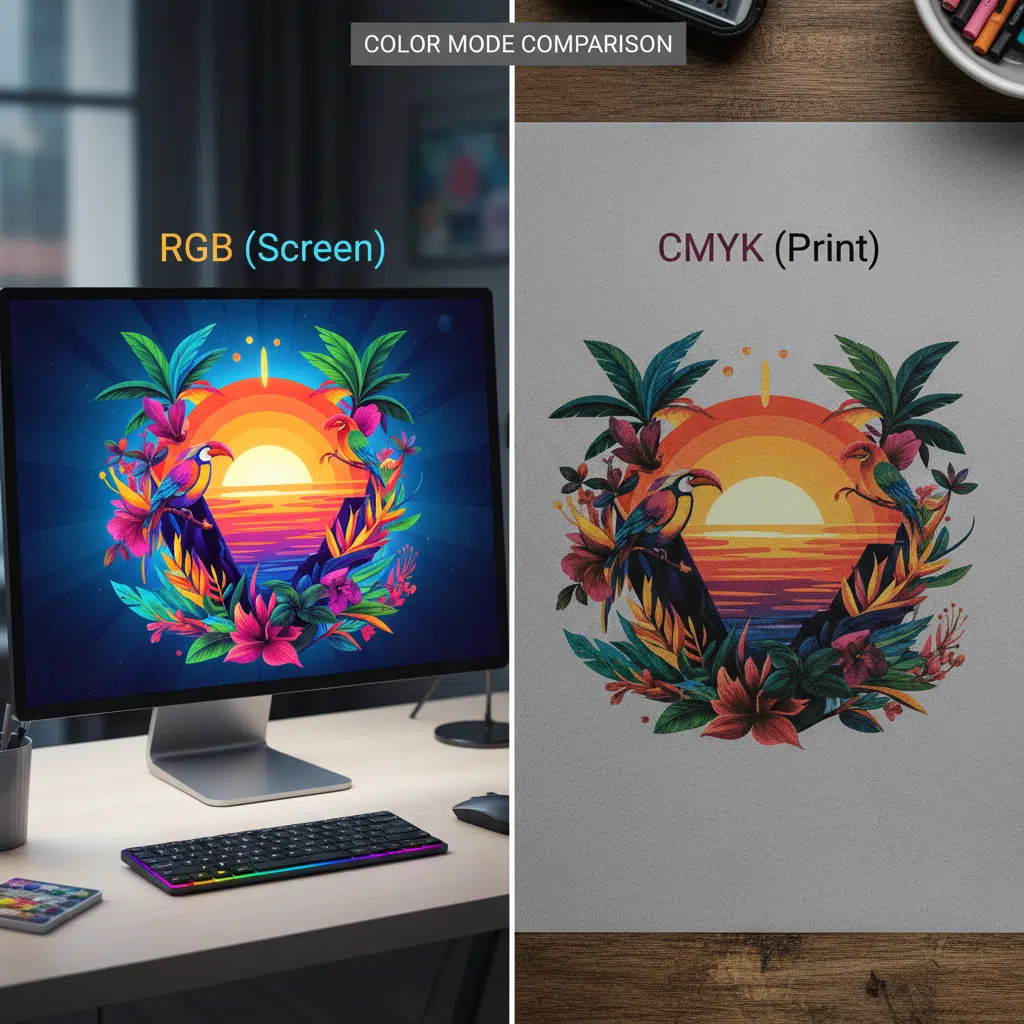

- Limitations: Computer monitors emit light (RGB), while printed paper reflects light (CMYK). Even on calibrated monitors, a screen cannot perfectly simulate how ink absorbs into a specific paper stock (dot gain) or how a matte finish affects color vibrancy.

2. Hard Proofs (Physical Proofs)

A hard proof is a physical sample mailed to you. In the professional printing industry, these generally fall into two categories:

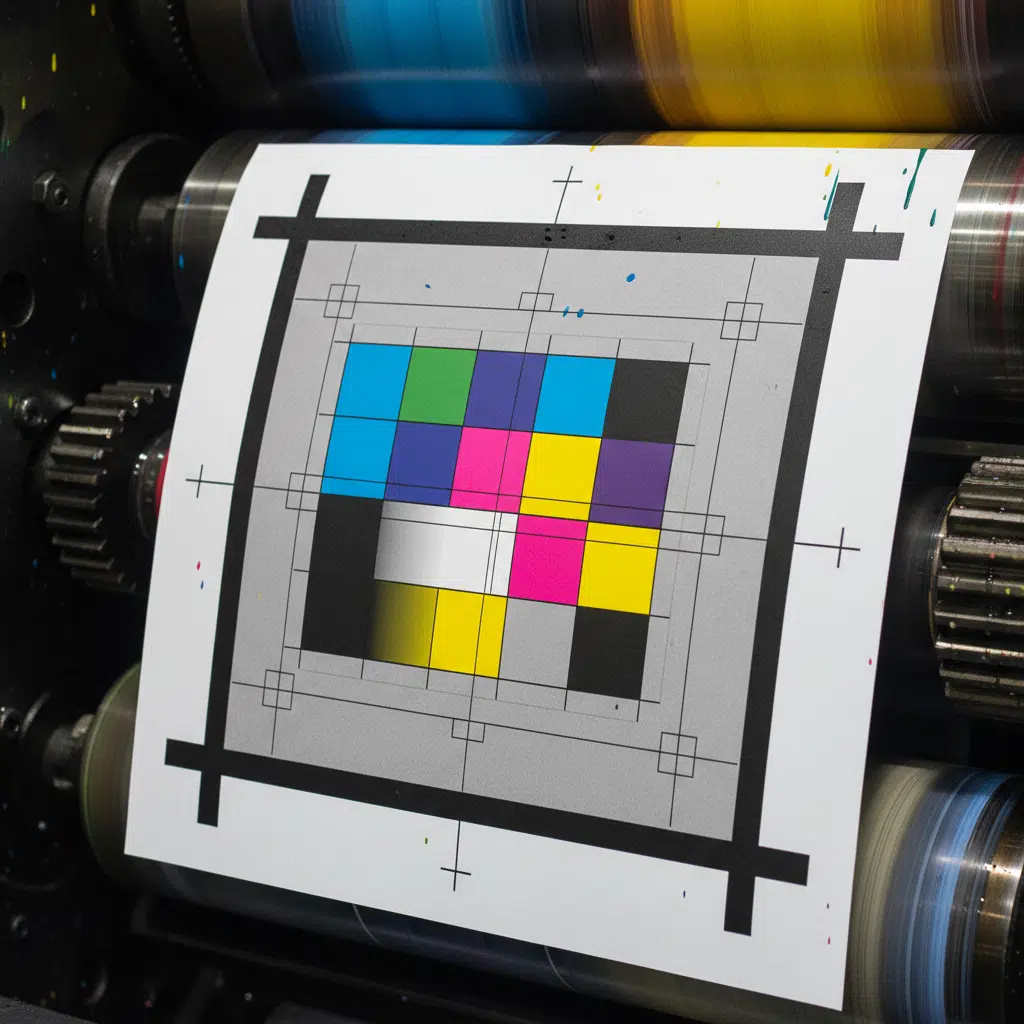

- Digital Hard Proof (Contract Proof): Produced on high-end inkjet printers calibrated to match the color profile of the offset press (e.g., ISO 12647 standards). These are highly accurate for color but may not use the exact final paper stock.

- Wet Proof (Offset Proof): The most accurate and expensive option. The design is printed using the actual printing plates, the actual ink, and the actual paper stock on an offset press. This is a true prototype of mass production.

Why Invest in Hard Proof Printing?

Relying solely on a screen view can lead to “expectation gaps” when the pallets arrive. Here is why hard proofs are often a necessary insurance policy for B2B buyers.

Color Calibration and Consistency

Colors shift depending on the substrate. A “Royal Blue” will look vibrant on gloss coated paper but may appear darker and more muted on uncoated kraft material due to ink absorption. A hard proof reveals these shifts before you print 10,000 units. It allows your brand team to verify that the CMYK conversion matches your corporate identity guidelines.

Paper and Material Interaction

Touching the material is part of the user experience. A physical sample allows you to assess the paper weight (GSM), texture, and stiffness. It also helps verify structural integrity—ensuring that a packaging box folds correctly without cracking at the seams or that a book binding opens flat as intended.

Verifying Special Finishes

Luxury printing often involves finishes that cannot be rendered on a PDF. If your project involves spot UV, hot foil stamping, embossing, or soft-touch lamination, a hard proof (specifically a wet proof or a finished sample) is the only way to inspect the registration and tactile quality of these effects.

When to Request a Wet Proof

Because wet proofs involve setting up printing plates and running a machine, they carry significant setup costs. They are not necessary for every job. Use the following criteria to decide:

| Scenario | Recommended Proof Type | Reasoning |

|---|---|---|

| Standard Marketing Flyers | Digital PDF | Low financial risk; color precision is rarely critical. |

| Corporate Catalogs | Digital Hard Proof | Ensures images and brand colors are accurate without full press setup costs. |

| Luxury Packaging / High Volume | Wet Proof | High financial risk. Material texture and exact color matching are essential. |

| Complex Pantone Matching | Wet Proof / Drawdown | Pantone (PMS) inks must be physically mixed and tested on the specific paper. |

How to Inspect Your Hard Proof

Once you receive your physical proof, use this checklist to verify quality effectively:

- Lighting Conditions: View the proof under standard daylight (D50 lighting) if possible. Office fluorescent lights or warm home lighting can distort color perception.

- Text Sharpness: Check small text for clarity. Ensure black text is set to 100% K (black ink only) rather than rich black (CMYK mix), which can cause fuzziness if registration is slightly off.

- Images and Gradients: Look for “banding” in gradients and ensure high-resolution images appear crisp, not pixelated.

- Bleed and Trim: Verify that background colors extend to the bleed line and that critical text is well within the safety margin to avoid being cut off.

Common FAQs About Printing Proofs

Does a hard proof match the final print 100%?

A wet proof will match 95-100% because it uses the same process. A digital hard proof is typically 90-95% accurate for color but may differ in surface texture. It is the industry standard for balancing cost and accuracy.

How much extra time does a hard proof add?

You should factor in shipping times (typically 3–5 days for international courier) plus 1–3 days for production. While it extends the lead time, it prevents the weeks of delay caused by a rejected mass production run.

What is an “Ink Drawdown”?

An ink drawdown is a smear of a specific Pantone ink on your chosen paper stock. It is a cheaper alternative to a full wet proof if you only need to verify a specific brand color.

Secure Your Production Quality

Skipping the hard proof stage to save time or money is a gamble that often leads to higher costs in the long run. Whether you need a complex book printing sample or a precise packaging prototype, verifying your specifications before mass production is the hallmark of professional procurement.

At YBJ Printing, we understand the precision required for international B2B orders. We offer various proofing levels to match your budget and risk profile, ensuring the final delivery meets your exact expectations.

Ready to start your project with confidence? Contact us today to discuss your specifications and request a sample.